What is Welded Wire and How to Choose the Right Type for Your Projects

Welded wire is a versatile and essential material used across various industries, ranging from construction and agriculture to fencing and reinforcement applications. According to a recent industry report by Grand View Research, the global welded wire market is expected to witness substantial growth, driven by increasing investments in infrastructure and urban development projects. This highlights the importance of selecting the appropriate type of welded wire for specific projects, as the right choice can enhance durability, safety, and overall effectiveness.

Welded wire is a versatile and essential material used across various industries, ranging from construction and agriculture to fencing and reinforcement applications. According to a recent industry report by Grand View Research, the global welded wire market is expected to witness substantial growth, driven by increasing investments in infrastructure and urban development projects. This highlights the importance of selecting the appropriate type of welded wire for specific projects, as the right choice can enhance durability, safety, and overall effectiveness.

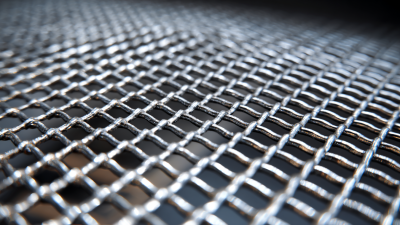

When choosing welded wire, it's crucial to consider factors such as wire gauge, spacing, and coating type, which significantly impact the material's strength and corrosion resistance. For example, galvanized welded wire is favored in outdoor applications due to its resistance to rust and environmental degradation, making it an ideal choice for agricultural fencing and garden structures. Industry experts emphasize the need for thorough knowledge of welded wire specifications to ensure optimal performance and compliance with safety standards in various applications.

In this guide, we will explore the different types of welded wire available on the market and provide insights into how to choose the right type for your specific projects, ensuring that you make informed decisions that align with industry standards and project requirements.

Understanding Welded Wire: Definition and Common Applications

Welded wire is a versatile construction material made from intersecting steel wires that are welded together at their joints. Defined primarily by its strength and durability, it is widely used across various industries, including agriculture, construction, and landscaping. According to a report by Grand View Research, the global welded wire market size was valued at approximately $3.5 billion in 2022, with expectations to expand as the demand for reinforced structures increases. This surge is attributed largely to the material's adaptability to various applications, such as fencing, concrete reinforcement, and architectural designs.

Welded wire is a versatile construction material made from intersecting steel wires that are welded together at their joints. Defined primarily by its strength and durability, it is widely used across various industries, including agriculture, construction, and landscaping. According to a report by Grand View Research, the global welded wire market size was valued at approximately $3.5 billion in 2022, with expectations to expand as the demand for reinforced structures increases. This surge is attributed largely to the material's adaptability to various applications, such as fencing, concrete reinforcement, and architectural designs.

In construction, welded wire fabric provides structural integrity to concrete slabs and walls, effectively redistributing load and preventing cracking. A study published by the American Concrete Institute revealed that using welded wire in concrete significantly improves tensile strength by up to 40%. Additionally, in agricultural applications, welded wire is commonly employed for livestock enclosures and crop protection, ensuring longevity and resistance to harsh environmental conditions. As industries continue to evolve, the influence of welded wire in enhancing safety and efficiency is paramount, making it an essential material for modern projects.

The Benefits of Using Welded Wire in Various Projects

Welded wire has gained popularity in various construction and landscaping projects due to its remarkable benefits. According to a report by MarketsandMarkets, the global wire mesh market is expected to reach $5.25 billion by 2026, driven by increased demand in the construction sector. This growth highlights the advantages that welded wire brings, such as strength and durability. Unlike traditional fencing, welded wire offers enhanced structural integrity, making it suitable for applications ranging from garden fencing to concrete reinforcement.

Another significant benefit of welded wire is its versatility. With different gauge sizes and mesh openings available, it can be tailored to meet the specific needs of any project. Whether used in forming cages for animals, creating trellises for plants, or providing support in industrial applications, welded wire's adaptability is evident. The American Society of Civil Engineers states that structures reinforced with welded wire fabric show an increase in performance compared to those without it, which can be attributed to its ability to distribute loads evenly. This makes it an ideal choice for engineers and contractors seeking reliable solutions in diverse projects.

How to Assess the Quality of Welded Wire Materials

When selecting welded wire for your projects, assessing the quality of the materials is paramount. Quality can be determined through various factors, including the type of welding process, the wire's composition, and the overall consistency of the welds. For instance, the Mn-content in ER5356 welding rods is known to significantly influence the mechanical properties of aluminum alloy joints. Research indicates that higher manganese content enhances tensile strength and improves resistance to cracking, which is crucial for durable applications.

**Tips:** When evaluating welded wire, always check for detailed product specifications and consider conducting ultrasonic testing (UT) to inspect the integrity of the welds. This non-destructive testing method is effective in revealing internal flaws that traditional inspections might overlook. Additionally, look for suppliers who provide thorough certification of their materials, as this speaks to their commitment to quality assurance.

Furthermore, understanding the market trends is essential. The welding materials market, which includes electrodes and filler materials, has been projected to grow significantly, driven by advancements in welding technology and increasing end-use applications. Awareness of these trends can guide you in choosing the right type of welded wire that meets your specific project needs while ensuring long-lasting performance.

Choosing the Right Welded Wire: Key Factors to Consider

When choosing the right welded wire for your projects, several key factors should be considered. First, assess the intended use of the welded wire. Different applications, such as fencing, reinforcement, or security, require various specifications in terms of wire gauge, mesh size, and material type. For example, a project that demands high durability may benefit from heavier gauge wire, while more flexible projects might require lighter options.

Next, evaluate the environmental conditions to which the welded wire will be exposed. Corrosion resistance can be crucial for outdoor applications, so opting for galvanized or stainless steel can enhance the longevity of your structure. Additionally, consider the mesh size, as smaller openings can provide better containment and security, while larger openings might be suitable for ventilation and visibility. Taking these factors into account ensures that you select the right welded wire that meets both your functional needs and durability requirements.

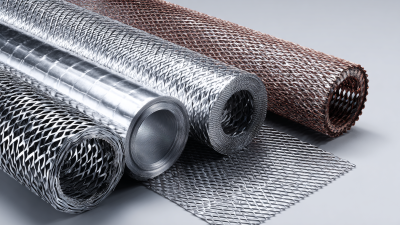

Top Types of Welded Wire for Different Project Needs

Welded wire is a versatile material used in a variety of projects, offering strength and durability for numerous applications. When selecting the right type of welded wire, it’s essential to consider the specific needs of your project, including weight capacity, corrosion resistance, and spacing dimensions. Different types of welded wire include standard welded wire mesh, heavy-duty mesh, and specialized types designed for agricultural or industrial use. Each type serves a unique purpose, making it crucial to choose wisely.

**Tips:** When choosing welded wire, evaluate the environmental factors your project will face. For outdoor applications, stainless steel may be preferable due to its superior resistance to rust and corrosion. Additionally, if your project requires support for heavy loads, opt for heavy-duty welded wire for enhanced stability. Lastly, always consider the spacing of the wire intersections; closer spacing provides more strength and prevents smaller items from falling through.

Each welded wire type has its own set of characteristics tailored for different needs. For instance, welded wire for fencing is designed to keep animals secure, while the type used in construction focuses on load-bearing capabilities. By understanding these distinctions, you can select the ideal welded wire that aligns with your project’s requirements.

Top Types of Welded Wire for Different Project Needs

This chart illustrates the most common types of welded wire used in various projects along with their typical uses. Each type serves unique purposes based on its characteristics.

Related Posts

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

Enhancing Safety and Durability: The Essential Role of Aluminum Stair Treads in Public Infrastructure

-

Enhancing Safety and Style: The Ultimate Guide to Choosing Steel Stair Treads for Your Home

-

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics