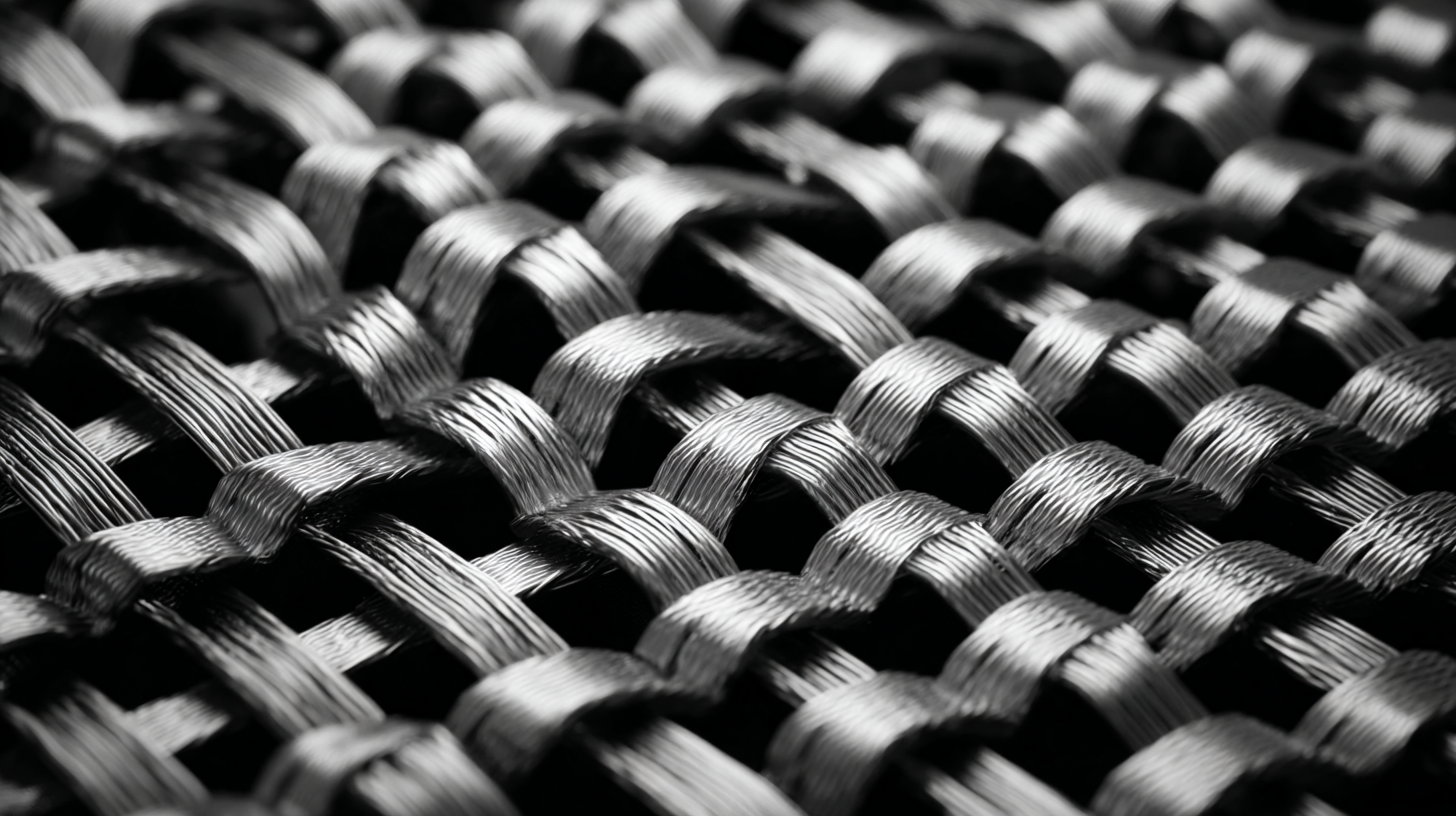

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

The modern design and engineering landscape is increasingly embracing the versatility of metal mesh screens, a feature that blends functionality with aesthetics. According to a recent report by MarketsandMarkets, the global metal mesh screen market is projected to grow from USD 900 million in 2023 to USD 1.2 billion by 2028, reflecting a CAGR of 6.1%. This growth is driven by the rising demand in various sectors, including architecture, aerospace, and automotive, where metal mesh screens are celebrated for their unique properties such as durability, lightweight design, and customizable dimensions.

Industry expert Dr. James Reynolds, a leading researcher in materials engineering, has remarked, "The adaptability of metal mesh screens allows them to serve multiple roles, from structural elements to decorative features, making them indispensable in innovative design." The incorporation of metal mesh screens in modern projects not only enhances visual appeal but also offers practical solutions for ventilation, privacy, and safety. As architects and engineers explore new frontiers in material science, the potential applications for metal mesh screens continue to expand, shaping the future of sustainable and effective design solutions.

Versatile Applications of Metal Mesh Screens in Architecture and Interior Design

Metal mesh screens have emerged as a pivotal element in contemporary architecture and interior design, thanks to their adaptability and aesthetic appeal. These screens serve various functions, ranging from providing privacy and security to enhancing ventilation and natural light. In public spaces, such as shopping malls and airports, metal mesh screens can act as both decorative features and functional barriers, allowing for a sense of openness while maintaining safety. Their lightweight nature and durability also make them ideal for use in façades, where they contribute to energy efficiency and climate control.

In interior design, metal mesh screens are increasingly being utilized to create distinct zones within open spaces. They can define dining areas in restaurants or separate workspaces in offices without closing off the environment entirely. By incorporating different patterns and finishes, designers can achieve a balance between industrial aesthetics and modern elegance. The versatility of metal mesh screens allows them to blend seamlessly into various design themes, making them a preferred choice for innovative projects that seek to marry form with function.

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

| Application Area | Material Type | Key Benefits | Design Considerations |

|---|---|---|---|

| Architecture | Stainless Steel | Durability, Aesthetic Appeal | Corrosion Resistance, Load-Bearing Capacity |

| Interior Design | Aluminum | Lightweight, Versatility | Color Finish Options, Custom Shapes |

| Safety & Security | Woven Wire Mesh | Visibility, Resistance to Impact | Mesh Size, Frame Design |

| Acoustic Management | Perforated Mesh | Sound Absorption, Aesthetic Integration | Hole Pattern, Material Density |

| HVAC Systems | Galvanized Steel | Corrosion Resistance, Strength | Design for Airflow, Maintenance Accessibility |

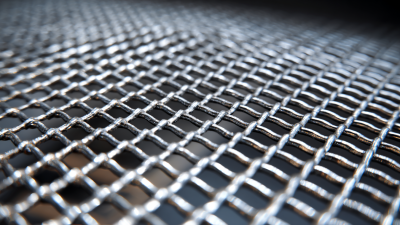

Enhancing Acoustic Performance with Metal Mesh Panels in Public Spaces

The use of metal mesh panels in public spaces is becoming increasingly popular due to their exceptional acoustic performance. According to a report by the American National Standards Institute (ANSI), improper acoustics in public areas can significantly affect occupant comfort and productivity, with up to 50% of individuals reporting difficulty concentrating in noisy environments.

Metal mesh screens are specifically designed to address these challenges, offering a unique blend of durability and sound absorption properties.

Recent studies indicate that metal mesh can reduce noise levels by up to 30%, making it an ideal solution for busy urban environments. These panels can be strategically installed in locations like restaurants, offices, and public transport systems, where noise reduction is crucial. The porous nature of metal mesh allows it to absorb sound waves, minimizing echoes and enhancing overall auditory experience.

Furthermore, the variety of designs and finishes available enables architects and designers to seamlessly integrate these panels into their projects while still achieving desired aesthetic and functional outcomes. As demand for improved acoustic solutions grows, metal mesh screens stand out as versatile and effective components in modern design and engineering.

The Role of Metal Mesh Screens in Sustainable Building Practices

Metal mesh screens have emerged as a pivotal component in sustainable building practices, offering a perfect blend of functionality and aesthetics. Their ability to allow natural light and ventilation while minimizing energy consumption makes them an ideal choice for modern architecture. By incorporating metal mesh screens, buildings can reduce reliance on artificial lighting and climate control systems, thus significantly decreasing their overall carbon footprint. Moreover, these screens can be integrated into façades and windows, enhancing buildings' thermal performance and contributing to energy efficiency.

In addition to their energy-saving attributes, metal mesh screens promote the use of sustainable materials. Many metal mesh options are made from recycled materials, minimizing resource extraction and waste. Their durability further emphasizes sustainability, as these products require less frequent replacement compared to traditional building materials. Furthermore, the adaptable nature of metal mesh allows for various designs, enabling architects to craft visually appealing structures that also prioritize environmental responsibility. Through innovative applications, metal mesh screens play an essential role in shaping a greener future in construction and design.

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

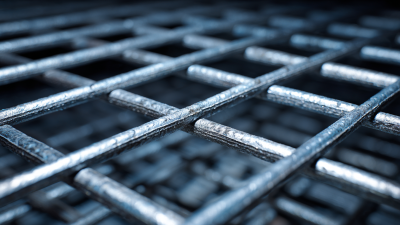

Innovative Uses of Metal Mesh in Industrial Equipment and Safety Solutions

Metal mesh screens have become essential in various industrial applications, offering innovative solutions that enhance both functionality and safety. In manufacturing, metal mesh is utilized in equipment such as filters and conveyor belts, where its durability and resistance to wear provide reliable performance. The openness of the mesh allows for efficient airflow and processing, making it ideal for ventilation systems, where it helps maintain optimal working conditions by reducing dust and contaminants.

Metal mesh screens have become essential in various industrial applications, offering innovative solutions that enhance both functionality and safety. In manufacturing, metal mesh is utilized in equipment such as filters and conveyor belts, where its durability and resistance to wear provide reliable performance. The openness of the mesh allows for efficient airflow and processing, making it ideal for ventilation systems, where it helps maintain optimal working conditions by reducing dust and contaminants.

In terms of safety, metal mesh screens play a critical role in safeguarding personnel and machinery. They are employed in applications like machine guarding and safety barriers, where they prevent accidents without obstructing visibility. Additionally, the robust nature of metal mesh ensures longevity and resistance to extreme conditions, making it suitable for hazardous environments. As industries continue to prioritize safety and efficiency, the versatility of metal mesh will undoubtedly lead to further innovative designs that meet modern engineering challenges.

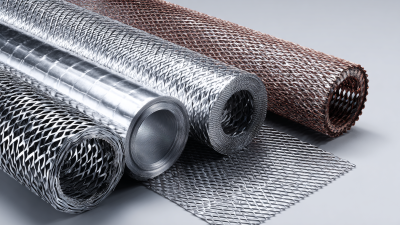

Future Trends: Advancements in Metal Mesh Technology for Smart Manufacturing

The advancement of metal mesh technology is set to significantly impact smart manufacturing, with trends indicating a convergence of innovative engineering solutions. As industries increasingly adopt automation, metal mesh screens provide unique advantages, such as lightweight strength and enhanced durability, making them ideal for modern applications. Their versatility supports various functions, from filtration to structural reinforcement, crucial in developing smart factories that prioritize agility and efficiency.

The advancement of metal mesh technology is set to significantly impact smart manufacturing, with trends indicating a convergence of innovative engineering solutions. As industries increasingly adopt automation, metal mesh screens provide unique advantages, such as lightweight strength and enhanced durability, making them ideal for modern applications. Their versatility supports various functions, from filtration to structural reinforcement, crucial in developing smart factories that prioritize agility and efficiency.

In the landscape of emerging technologies, metal mesh screens will likely see integration with AI and robotics, enabling more efficient production processes. This evolution aligns with the growing need for sustainable practices within manufacturing sectors, as companies seek to optimize resource use while maintaining high productivity levels. As we advance towards 2026, the interplay between metal mesh technology and intelligent supply chains is poised to redefine operational frameworks, creating environments that are not only faster and safer but also more predictable in their outputs.

Related Posts

-

Unlocking Strength: How Steel Mesh Reinforces Modern Construction Trends with 30% Increased Durability

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights

-

Choosing the Right Trench Drain Grate for Your Home Landscape Needs

-

Understanding the Benefits of Steel Grating in Industrial Applications

-

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications