Exploring the Versatility of Metal Mesh Screens: Innovative Applications Across Industries

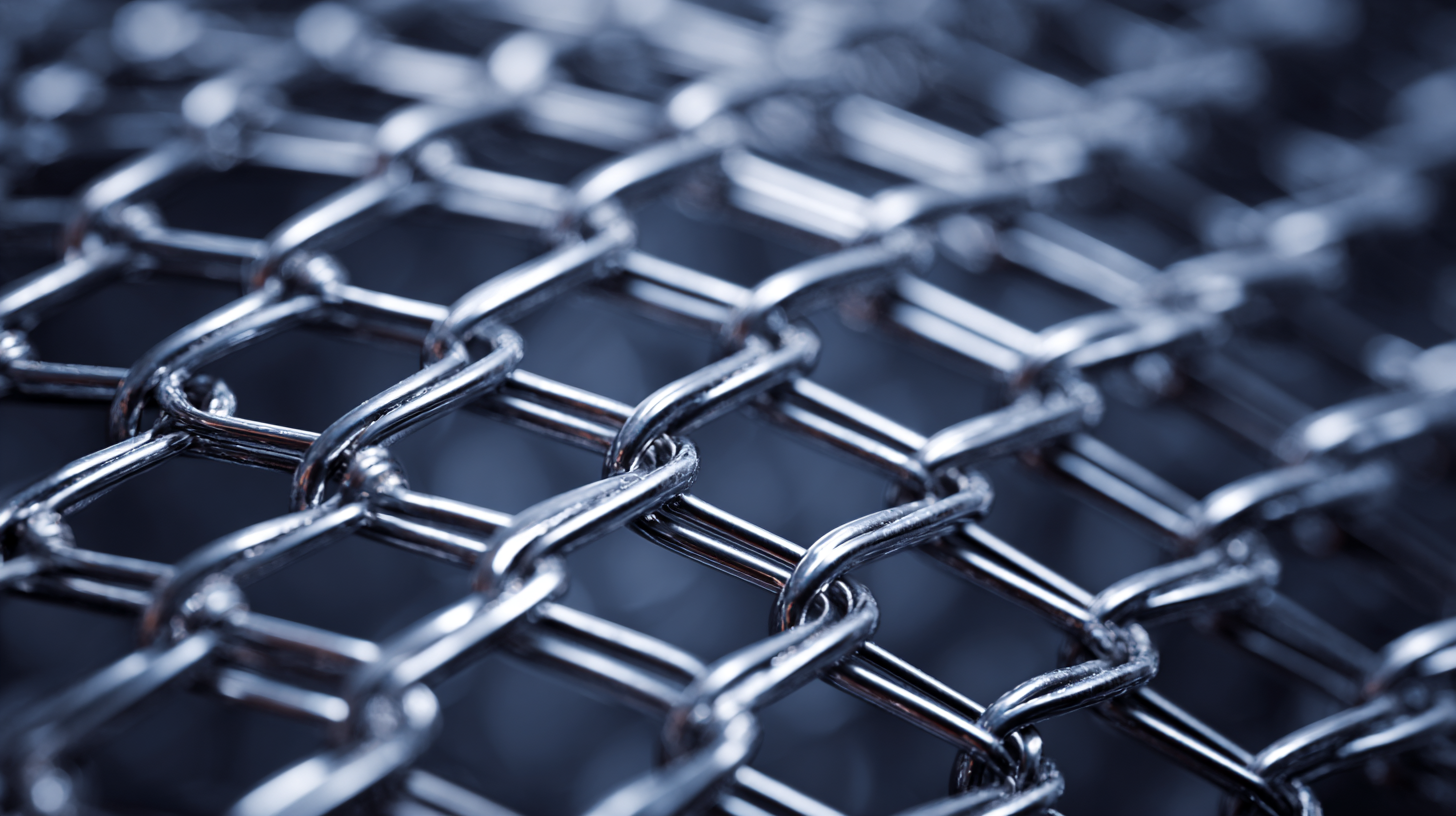

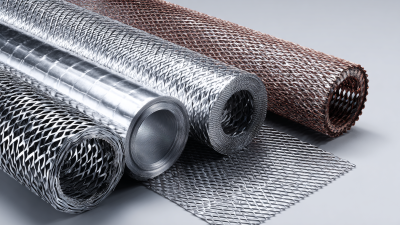

In today's rapidly evolving industrial landscape, the versatility of metal mesh screens has emerged as a significant topic of interest. These innovative materials, characterized by their intricate and flexible structures, are being increasingly utilized across various sectors, including architecture, filtration, automotive, and electronics.

A metal mesh screen not only offers aesthetic appeal but also enhances functional performance, making it a preferred choice for designers and engineers alike. From providing safety barriers to enabling efficient airflow in HVAC systems, the applications of metal mesh screens are vast and continually expanding. This exploration of their innovative applications highlights not just their practicality, but also their adaptability in addressing modern challenges, illustrating how they bridge the gap between form and function in numerous industries.

A metal mesh screen not only offers aesthetic appeal but also enhances functional performance, making it a preferred choice for designers and engineers alike. From providing safety barriers to enabling efficient airflow in HVAC systems, the applications of metal mesh screens are vast and continually expanding. This exploration of their innovative applications highlights not just their practicality, but also their adaptability in addressing modern challenges, illustrating how they bridge the gap between form and function in numerous industries.

Innovative Uses of Metal Mesh Screens in Architecture for Sustainable Design Solutions

Metal mesh screens have gained prominence in architectural design due to their versatility and sustainability benefits. According to a report by Research and Markets, the global architectural wire mesh market is projected to grow from $354.3 million in 2021 to $492.1 million by 2026, reflecting an increasing preference for environmentally conscious materials. Metal mesh screens not only enhance aesthetic appeal but also actively contribute to energy efficiency in buildings. For instance, these screens can regulate natural light, reducing the need for artificial lighting and lowering energy consumption.

In sustainable design, metal mesh screens offer innovative solutions for ventilation and climate control. A study published in the Journal of Green Building highlights that using metal mesh as a shading device can lead to energy savings of up to 30% in commercial buildings. Additionally, their ability to allow airflow while minimizing heat gain makes them an ideal choice for passive cooling strategies. These attributes support the growing emphasis on eco-friendly design, aligning with the architectural community's commitment to sustainable practices. As cities continue to evolve, the application of metal mesh screens is likely to expand, providing both functional and aesthetic benefits while addressing the challenges of modern architecture.

Enhancing Filtration Efficiency in Water Treatment: The Role of Metal Mesh Screens

Metal mesh screens play a pivotal role in enhancing filtration efficiency in water treatment processes. These screens, characterized by their robust structure and fine openings, facilitate the removal of impurities while allowing for the efficient passage of water. According to a report by Grand View Research, the global water treatment market is projected to reach $1.3 trillion by 2025, highlighting the increasing need for effective filtration solutions. Metal mesh screens are at the forefront of this trend, empowering facilities to maintain high water quality standards while minimizing energy consumption and operational costs.

Furthermore, the versatility of metal mesh screens extends beyond traditional filtration. A study published in the Journal of Environmental Engineering found that integrating advanced metal mesh designs can enhance nanoparticle capture rates by up to 30%, significantly improving water purity. This innovation not only addresses growing environmental concerns but also aligns with regulatory mandates to ensure cleaner water. As industries strive to comply with stricter water quality regulations, the adoption of metal mesh screens in treatment facilities is expected to accelerate, making them an essential component in modern water management systems.

Exploring the Versatility of Metal Mesh Screens: Innovative Applications Across Industries - Enhancing Filtration Efficiency in Water Treatment: The Role of Metal Mesh Screens

| Application Area | Material Type | Mesh Size (microns) | Filtration Efficiency (%) | Common Uses |

|---|---|---|---|---|

| Municipal Water Treatment | Stainless Steel | 100 | 95 | Removal of large particulates |

| Industrial Wastewater Treatment | Galvanized Steel | 50 | 90 | Suspended solids removal |

| Food and Beverage Filtration | Nickel Alloy | 150 | 97 | Clarification of liquids |

| Chemical Processing | Carbon Steel | 200 | 85 | Particle removal in solvents |

| Aquaculture | Bronze | 75 | 92 | Filter feed and debris |

Revolutionizing Automotive Engineering: Metal Mesh in Lightweight and Durable Components

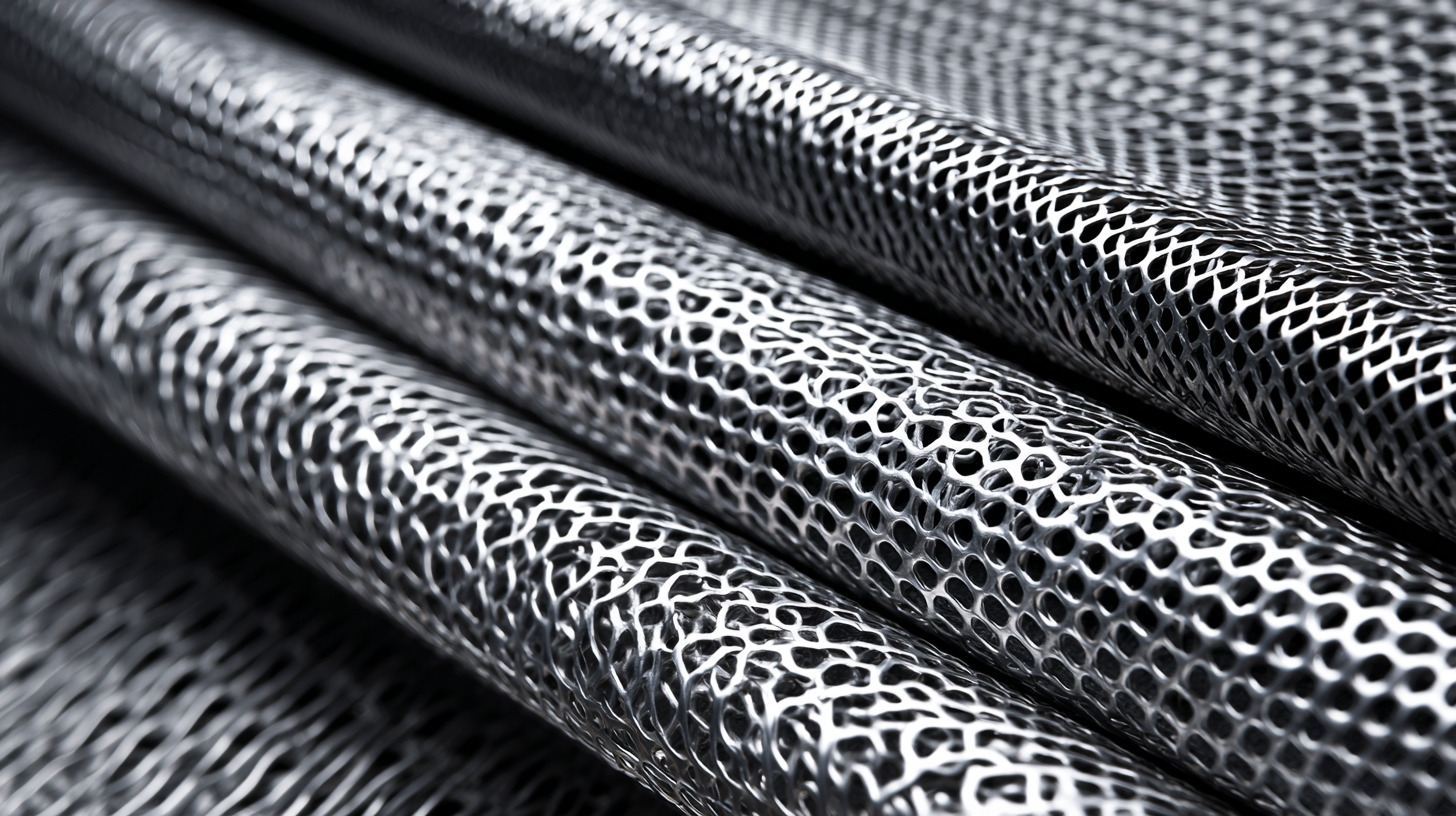

Metal mesh screens are revolutionizing automotive engineering by enabling the production of lightweight and durable components. The automotive industry has long sought ways to improve fuel efficiency and vehicle performance without compromising structural integrity. By incorporating metal mesh into various parts of vehicles—such as chassis, body panels, and even interior elements—manufacturers can significantly reduce weight while enhancing strength.

The unique properties of metal mesh, including its high tensile strength and flexibility, allow for innovative designs that were previously unattainable with traditional materials. For instance, metal mesh can be used in the creation of custom heat exchangers, which improve engine cooling efficiency. Additionally, its porous nature aids in reducing turbulence, which can enhance aerodynamic performance. As a result, metal mesh is becoming an essential component in the quest for more efficient and resilient automotive designs, paving the way for the next generation of vehicles that are not only lighter but also more sustainable.

Metal Mesh Screens in Electronics: Improving Heat Dissipation and Signal Integrity

Metal mesh screens have emerged as a crucial component in many electronic devices, primarily due to their ability to improve heat dissipation and signal integrity. These screens are made from fine metallic wires woven together, allowing them to act as effective thermal conductors. In high-performance electronics, such as smartphones and computers, managing heat is essential to ensure optimal functionality and longevity. The incorporation of metal mesh screens helps in distributing heat evenly across components, thereby preventing hotspots and reducing the risk of thermal damage.

Moreover, metal mesh screens play a key role in enhancing signal integrity. In wireless communication devices, for instance, they can minimize interference and improve the quality of signal transmission. By acting as a filter, metal mesh screens can reduce unwanted electromagnetic interference while allowing desired signals to pass through. This attribute is especially beneficial in densely packed electronic environments, where maintaining signal clarity is paramount. As industries continue to evolve, the versatility of metal mesh screens in electronics is set to drive innovative solutions that meet the increasing demands for performance and reliability.

Advancements in Agricultural Technology: Utilizing Metal Mesh Screens for Enhanced Crop Production

The agricultural technology sector is witnessing remarkable advancements aimed at enhancing crop production, particularly through the innovative use of metal mesh screens. As the global agricultural film market is projected to grow from $11.96 billion in 2024 to $19.66 billion by 2032, with a compound annual growth rate (CAGR) of 6.3%, it is clear that the integration of modern materials and methods is becoming pivotal in meeting the increasing demands of food production.

Metal mesh screens are playing a crucial role in controlled environment agriculture (CEA), providing efficient filtration and cultivation solutions that augment plant health and yield.

Research highlights the importance of technological progress in agricultural modernization as a core component of rural revitalization strategies. As the global population is expected to surpass 9 billion by 2050, the application of innovative practices, such as those utilizing metal mesh screens, becomes essential. These screens facilitate better resource management and pest control, contributing to increased agricultural resilience and productivity. With the 2025 Central Document No. 1 emphasizing the reinforcement of food supply capabilities, the role of advanced materials in agriculture will be indispensable for future food security and sustainability.

Related Posts

-

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Understanding the Benefits of Steel Grating in Industrial Applications

-

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China