The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

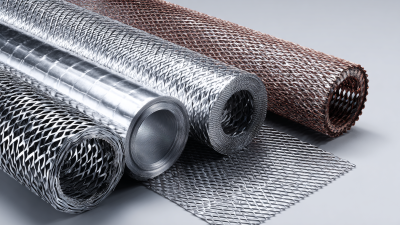

In recent years, the versatility of stainless steel mesh screens has gained significant recognition across various industries due to their robust characteristics and numerous benefits. According to a report by Grand View Research, the global stainless steel market is projected to reach $141.34 billion by 2025, partly driven by the increasing demand for stainless steel mesh screens in applications such as filtering, separation, and security. These screens not only provide exceptional strength and durability but also possess corrosion resistance, making them ideal for both indoor and outdoor usage. With applications ranging from industrial filtration to architectural design, the adoption of stainless steel mesh screens is on the rise, enhancing efficiency and safety in everyday functions. This article will explore the myriad advantages and practical uses of stainless steel mesh screens, demonstrating their essential role in modern applications.

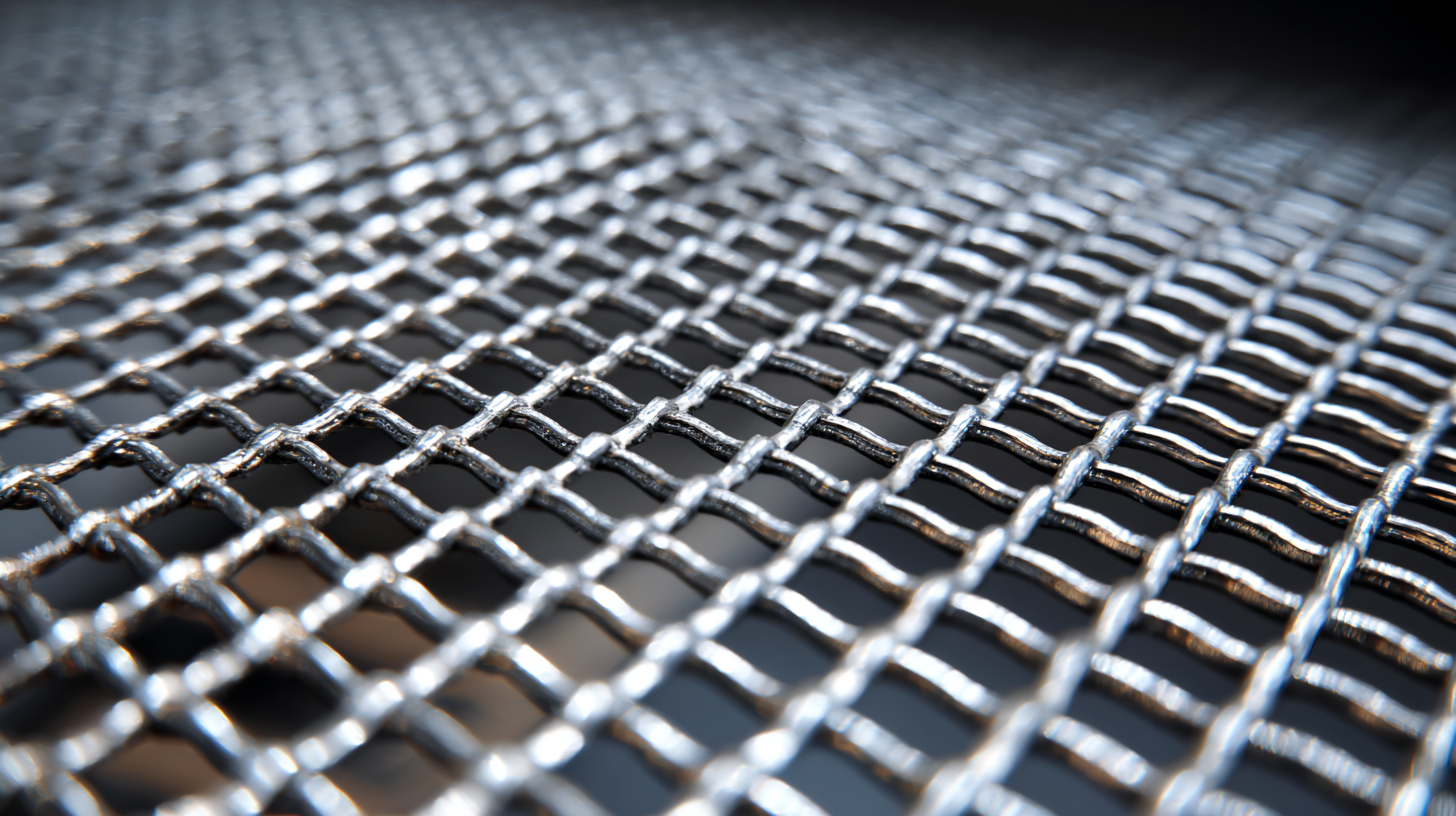

Understanding the Unique Properties of Stainless Steel Mesh Screens

Stainless steel mesh screens are known for their unique properties, making them an ideal choice for a myriad of applications. The inherent strength and durability of stainless steel ensure that these screens can withstand high temperatures and corrosive environments, which is essential in industries like food processing, pharmaceuticals, and construction. Moreover, stainless steel is non-reactive, meaning it won’t leach chemicals or contaminate products, making it a safe option for usage in various contexts, from kitchen applications to industrial filtration systems.

Stainless steel mesh screens are known for their unique properties, making them an ideal choice for a myriad of applications. The inherent strength and durability of stainless steel ensure that these screens can withstand high temperatures and corrosive environments, which is essential in industries like food processing, pharmaceuticals, and construction. Moreover, stainless steel is non-reactive, meaning it won’t leach chemicals or contaminate products, making it a safe option for usage in various contexts, from kitchen applications to industrial filtration systems.

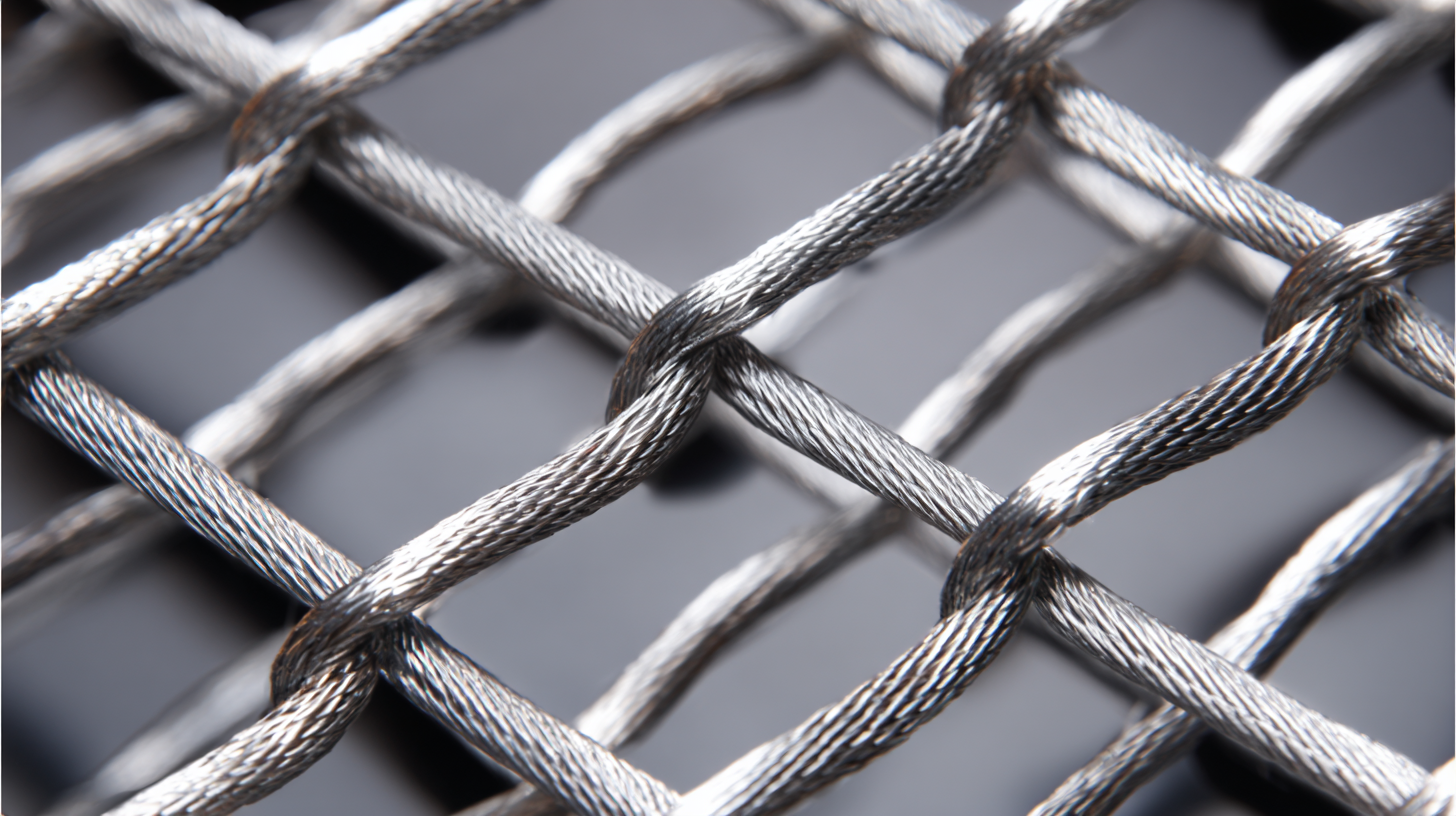

When choosing stainless steel mesh screens, consider the mesh size and wire diameter to suit your specific needs. A finer mesh is suitable for applications requiring detailed filtration, while a coarser mesh might be better for supporting heavier materials. Tip: Always ensure the screen is properly cleaned and maintained to prolong its lifespan and effectiveness. Additionally, be mindful of the environmental conditions it will be exposed to; screens in humid or corrosive settings may benefit from a passivation process to enhance corrosion resistance.

Stainless steel mesh screens are not only practical but also versatile. They can be utilized in decorative applications, such as architectural designs and art installations, owing to their aesthetic appeal and modern look. Tip: When using stainless steel mesh in decorative projects, pairing it with LED lighting can create stunning visual effects. By understanding these unique properties, users can harness the full potential of stainless steel mesh screens across various everyday applications.

Identifying Everyday Applications for Stainless Steel Mesh Screens

Stainless steel mesh screens are increasingly becoming indispensable in various everyday applications, owing to their durability and versatility. These screens are employed in numerous sectors, including healthcare, where they are crucial for filtering and maintaining clean environments. For instance, they are utilized in medical devices to ensure that particulate matter does not interfere with operations, ultimately improving patient care and safety.

Beyond healthcare, stainless steel mesh screens find extensive use in industrial settings, particularly in processes involving fluid filtration and separation. Their ability to withstand harsh chemicals and temperatures makes them ideal for manufacturing environments, where consistent performance is critical. Additionally, advances in printing technologies have further expanded their application, enabling the creation of high-performance sensors that can be integrated into everyday devices. By enhancing the resolution and functionalities of screen-printed materials, these screens not only contribute to industrial efficacy but also improve the usability of consumer electronics.

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

| Application | Benefits | Material Properties | Common Uses |

|---|---|---|---|

| Filtration Systems | Durable, resistant to corrosion | Non-reactive, easy to clean | Water purification, oil filtration |

| Architectural Features | Aesthetic appeal, strength | Lightweight, high tensile strength | Balustrades, building facades |

| Agricultural Screens | Effective pest control, durability | Weather-resistant, long-lasting | Greenhouses, grain storage |

| Industrial Applications | Safety and functionality | High heat resistance, non-corrosive | Equipment guards, machinery enclosures |

| Kitchen Tools | Easy maintenance, hygienic | Non-staining, dishwasher safe | Sifters, strainers, cooking vessels |

Step-by-Step Guide to Choosing the Right Stainless Steel Mesh Screen

When choosing the right stainless steel mesh screen for your needs, it's essential to consider several key factors. First, determine the screen's intended application—different situations may require specific mesh sizes and types. For instance, a finer mesh is ideal for preventing small particles from passing through, while a coarser option may be more appropriate for filtering larger debris.

Next, evaluate the material quality, as various grades of stainless steel offer different levels of corrosion resistance and durability. For outdoor applications or environments prone to moisture, opting for a higher-grade stainless steel, such as 316, can enhance longevity. Additionally, consider the wire diameter and weave pattern; these attributes not only affect strength but also influence the airflow and visibility through the mesh. By thoroughly assessing these factors, you can select a stainless steel mesh screen that perfectly aligns with your requirements, ensuring efficiency and effectiveness in its use.

The Versatility of Stainless Steel Mesh Screens

Maintenance Tips to Ensure Longevity of Stainless Steel Mesh Screens

To ensure the longevity of stainless steel mesh screens, proper maintenance is essential. Regular cleaning is a fundamental practice; using warm soapy water and a soft brush can effectively remove dirt and debris. Avoid abrasive cleaners or materials that could scratch the surface, as scratches can weaken the metal and lead to corrosion over time. Additionally, rinsing with clean water and drying with a soft cloth will help prevent water spots and further corrosion.

To ensure the longevity of stainless steel mesh screens, proper maintenance is essential. Regular cleaning is a fundamental practice; using warm soapy water and a soft brush can effectively remove dirt and debris. Avoid abrasive cleaners or materials that could scratch the surface, as scratches can weaken the metal and lead to corrosion over time. Additionally, rinsing with clean water and drying with a soft cloth will help prevent water spots and further corrosion.

Another vital maintenance tip is to inspect the mesh screens periodically for any signs of wear or damage. Look for frayed edges, rust spots, or any distortion that may affect functionality. If any issues are detected, timely repairs or replacements can prevent more significant damage and ensure efficacy. When storing stainless steel mesh screens, keeping them in a dry environment is advisable, as moisture can accelerate rust formation. By following these simple maintenance tips, users can ensure their stainless steel mesh screens remain durable and effective for a variety of everyday applications.

Enhancing Efficiency with Custom Stainless Steel Mesh Screen Solutions

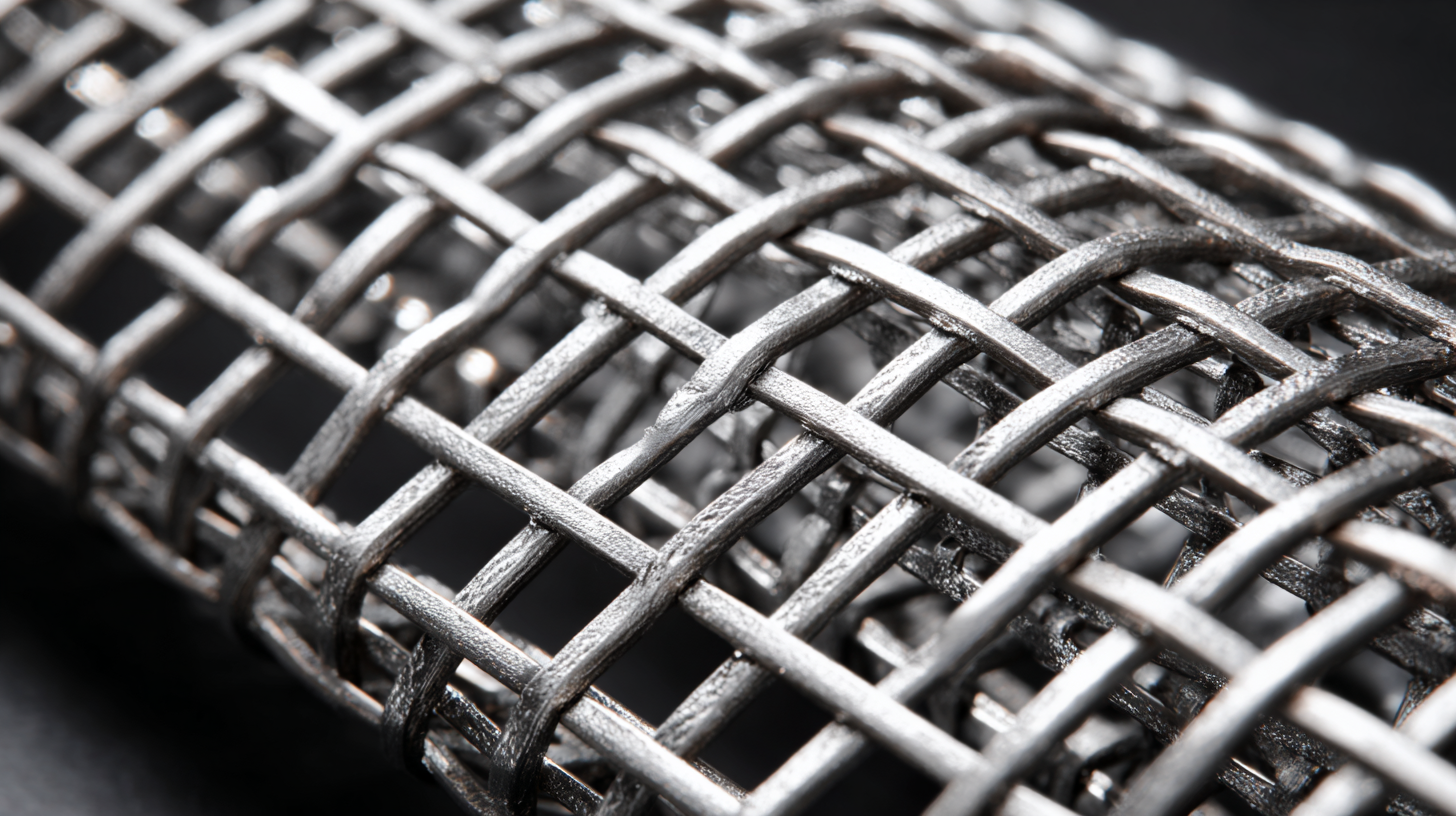

Stainless steel mesh screens have emerged as essential tools in various industries due to their durability, resistance to corrosion, and versatility. These screens can be custom-designed to fit specific applications, enhancing efficiency and functionality. Whether in food processing, construction, or filtration systems, tailored stainless steel mesh solutions can significantly improve operational productivity by accurately meeting the unique needs of each application.

When considering custom stainless steel mesh screens, it’s crucial to assess the specific requirements of your project. Here are a few tips to keep in mind:

- Evaluate the mesh size that best suits your application, as this affects both the filtration quality and flow rate.

- Consider the environment in which the mesh will be used; selecting the right grade of stainless steel can enhance durability and resistance against harsh conditions.

- Work closely with manufacturers to ensure the designs suit your operational needs perfectly.

By investing in custom stainless steel mesh screens, you can optimize processes while ensuring longevity and reliability. This strategic approach not only saves time but also reduces maintenance costs, ultimately contributing to a more efficient workflow across various everyday applications.

Related Posts

-

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China