What Are the Uses and Benefits of Stainless Steel Wire Mesh?

Stainless steel wire mesh has become a critical material in various industries. Its durability and resistance to corrosion make it ideal for numerous applications. From construction to agriculture, stainless steel wire mesh serves multiple purposes that enhance functionality and safety.

In construction, stainless steel wire mesh provides structural support and enhances strength. It is also used in filtration systems, ensuring clean water in urban settings. Additionally, this material offers protection against pests in agriculture, allowing crops to thrive without chemical interventions.

The versatility of stainless steel wire mesh is impressive. However, its high cost and maintenance requirements are worth considering. Users often need to evaluate the balance between benefits and drawbacks. In many cases, stainless steel wire mesh proves to be an invaluable investment, but it is important to weigh all factors before making a decision.

Uses of Stainless Steel Wire Mesh in Industrial Applications

Stainless steel wire mesh is commonly used in various industrial applications. Its durability and resistance to corrosion make it a preferred choice. In the food processing sector, for instance, stainless steel mesh ensures food safety. It prevents contamination while allowing for air circulation during drying processes. According to industry reports, over 40% of food manufacturers utilize stainless steel mesh to comply with safety regulations.

In the construction industry, stainless steel wire mesh is invaluable. It's employed in reinforcing concrete, helping to strengthen structures. A recent market analysis suggests that the construction sector represents roughly 30% of stainless steel wire mesh usage globally. The mesh also serves as a barrier against dust and debris at construction sites.

Tips: When selecting stainless steel wire mesh for your specific needs, consider both the gauge and the weave pattern. Not all types offer the same level of strength or flexibility. Remember, regular maintenance is key to prolonging the lifespan of the mesh. Inspect it periodically for any signs of wear or damage to maintain optimal performance.

Benefits of Stainless Steel Wire Mesh in Food Processing

In food processing, stainless steel wire mesh is essential. It offers a blend of strength and flexibility. This allows for multiple uses, including filtration and separation. The mesh can withstand high temperatures and various chemicals. It does not rust, which is crucial in wet environments. Contaminants are less likely to cling to its surface.

Food safety is paramount. Stainless steel wire mesh helps maintain hygiene. It is easy to clean, ensuring no residue remains. However, improper cleaning can lead to issues. It's important to establish a consistent cleaning routine. A neglected mesh can harbor bacteria and affect the food's safety.

The durability of stainless steel mesh also contributes to its value. It has a long lifespan, reducing the need for frequent replacement. Though it may be an initial investment, it pays off over time. But still, careful consideration is necessary to choose the appropriate wire mesh type. Every application is different. Not all types may suit specific processing needs. Balancing cost with quality is key, as is ongoing maintenance.

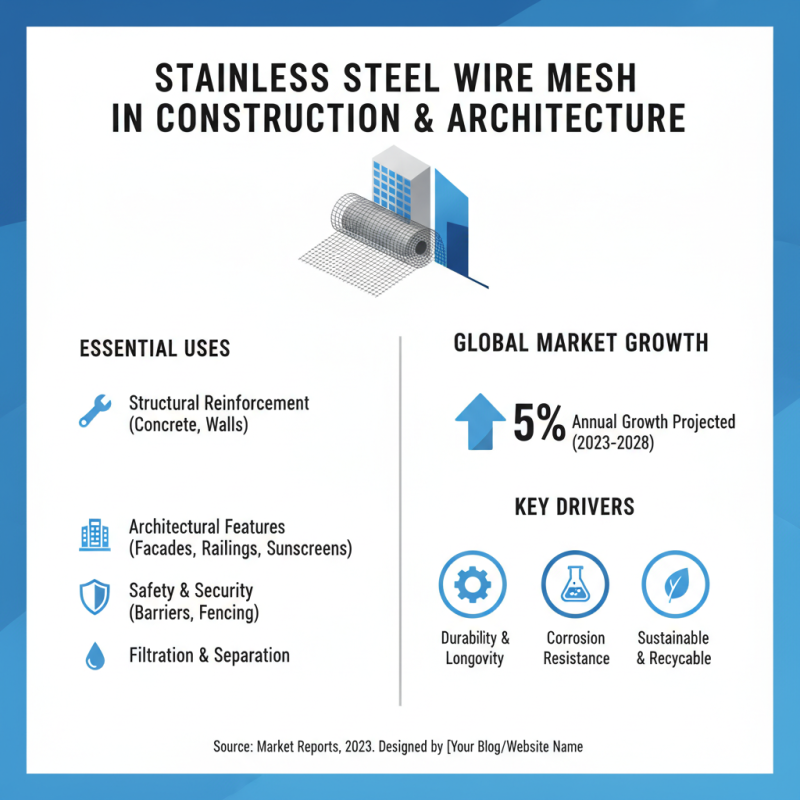

Applications of Stainless Steel Wire Mesh in Construction and Architecture

Stainless steel wire mesh has become essential in construction and architecture. Its uses are diverse, from reinforcement to decorative applications. According to market reports, the global demand for stainless steel in construction is projected to grow by about 5% annually. This demand stems from the material’s durability and resistance to corrosion.

In building facades, stainless steel wire mesh provides both aesthetic and functional benefits. It can enhance airflow while offering protection against the elements. Architects often use it for shade systems, allowing natural light while reducing heat. A study by the American Institute of Steel Construction emphasizes that stainless steel components can increase a building's lifespan by 30% compared to other materials.

However, while stainless steel wire mesh is durable, it is not without challenges. Installation can be complicated, requiring skilled labor to ensure proper fitting. Maintenance is another consideration, especially in coastal areas where salt can lead to corrosion over time. A balance between function and form is necessary to avoid issues down the line.

Advantages of Stainless Steel Wire Mesh for Filtration and Separation

Stainless steel wire mesh is widely used in various industries. Its strength and durability make it an ideal choice for filtration and separation processes. In water treatment facilities, this mesh efficiently captures contaminants. It prevents unwanted particles from entering the system. The uniform openings ensure consistent filtration. This reliability is crucial for maintaining water quality.

In food processing, stainless steel wire mesh offers an additional advantage. It is resistant to corrosion and high temperatures. This ensures the safety of food products. Moreover, its easy cleaning properties make it a popular choice. However, some users may find it challenging to achieve complete sanitation. Regular maintenance is essential to avoid potential contamination.

Another benefit is its versatility. Stainless steel mesh can be used in automotive and aerospace industries. It serves as a protective filter for various components. However, fabricators must consider the right specifications to avoid weaknesses in the design. Perfect customization can be tricky. Nevertheless, finding the right balance can enhance the effectiveness of applications.

What Are the Uses and Benefits of Stainless Steel Wire Mesh?

| Dimension | Use | Benefits |

|---|---|---|

| Aperture Size: 0.5 mm | Filtration of liquids | High flow rate and durability |

| Aperture Size: 1 mm | Separation of solid particles | Corrosion resistance and easy cleaning |

| Wire Thickness: 0.3 mm | Screening applications | Strength and flexibility |

| Custom Mesh Size | Architectural applications | Aesthetic appeal and structural support |

| Galvanized Finish | Outdoor applications | Enhanced weather resistance |

Maintenance and Durability of Stainless Steel Wire Mesh Products

Stainless steel wire mesh is celebrated for its exceptional durability and low maintenance needs. The material resists rust and corrosion, making it ideal for various environments. Unlike other materials, stainless steel withstands harsh weather and chemical exposure. This durability translates into longevity, reducing the need for frequent replacements. However, it's essential to ensure that the mesh is properly installed and maintained.

Regular cleaning is crucial to enhance the lifespan of stainless steel wire mesh. Dust and debris can accumulate, leading to potential corrosion if not addressed. A simple wash with soap and water often suffices, but some people overlook this step. Neglect can lead to costly repairs. It’s a stark reminder that even durable materials require care.

While stainless steel wire mesh is robust, it isn’t entirely impervious to damage. It can bend or warp under extreme pressure, which is a flaw worth considering. Understanding these limitations is vital for effective use. Reflecting on these aspects can lead to better decisions in choosing the right mesh for specific applications.

Uses and Benefits of Stainless Steel Wire Mesh

This bar chart illustrates the various applications of stainless steel wire mesh across different industries. The highest application area is in the Food Industry, followed by Construction, Filtration, Automotive, and Electronics. Stainless steel wire mesh is favored for its durability and resistance, making it a versatile choice across multiple sectors.

Related Posts

-

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

-

The Ultimate Guide to Choosing the Right Stainless Steel Mesh Screen for Your Home Projects

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Mesh

-

Top 10 Benefits of Using Welded Wire for Your Construction Projects

-

Top 2025 Stainless Steel Mesh Screen Uses and Benefits You Need to Know

-

How to Choose the Best Welded Wire for Your Projects and Applications