What is a Trench Drain Grate and How It Ensures Optimal Drainage Performance

In the world of efficient drainage solutions, the trench drain grate plays a crucial role in managing water runoff and ensuring optimal performance. According to drainage expert John Smith, “A well-designed trench drain grate not only enhances water management but also safeguards the integrity of surrounding structures.” This statement highlights the importance of selecting the right trench drain grate to prevent flooding and erosion, particularly in areas prone to heavy rainfall or where paved surfaces can lead to water accumulation.

Trench drain grates come in various materials and designs, each tailored to specific environments and load-bearing requirements. From residential settings to commercial applications, understanding the nuances of trench drain grates is essential for engineers and property owners alike. As urbanization continues to increase, the demand for reliable drainage systems that uphold both functionality and aesthetics has never been greater. By delving into the features and benefits of trench drain grates, we can uncover how they contribute not only to effective drainage but also to the overall safety and longevity of our infrastructure.

Understanding the Basics: What is a Trench Drain Grate?

A trench drain grate

is an essential component of a trench drainage system, designed to efficiently manage surface water runoff. Typically installed in low-lying areas, these grates cover a channel that directs rainwater or melted snow away from surfaces, preventing flooding and erosion.

The materials used for trench drain grates vary from stainless steel to polymer, each offering different levels of durability and corrosion resistance. According to a report from the American Society of Civil Engineers, poorly managed stormwater can lead to infrastructure damage costing billions of dollars annually. Thus, effective drainage solutions, including trench drain grates, are critical in urban planning and environmental management.

When selecting a trench drain grate, consider factors such as load rating and drainage capacity. Loading classes can significantly vary, so it’s essential to choose a grate that can withstand the expected traffic, be it pedestrian, vehicular, or heavy machinery. A recommended tip is to opt for grates with quick-release mechanisms for easier maintenance and cleaning.

Additionally, proper installation is crucial for optimal performance. Ensure that the trench is level and that the grate fits snugly into the channel. This can prevent debris accumulation, which may obstruct flow. Periodic inspections and maintenance will enhance the longevity of your trench drain system and its efficiency in managing water runoff.

Key Features of Trench Drain Grates for Enhanced Performance

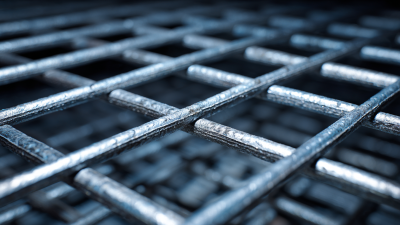

Trench drain grates play a crucial role in ensuring optimal drainage performance in various environments, from industrial sites to residential areas. One of the key features of these grates is their material composition, which often includes durable metals like stainless steel or heavy-duty polymer. These materials are designed to withstand heavy loads while resisting corrosion and wear, ensuring longevity and reliability under challenging conditions. The choice of material directly impacts the efficiency of water flow, allowing for rapid drainage and minimizing the risk of flooding.

Another important aspect is the design and shape of the grates. Many trench drain grates come with slotted or perforated patterns that facilitate maximum water entry while preventing debris from clogging the system. The size of the openings is engineered to balance flow rate and filtration, effectively channeling excess water away while keeping the surrounding area clean. Additionally, some models are designed with safety features such as slip-resistant surfaces, ensuring that foot traffic remains safe in wet conditions. Together, these key features enhance the performance of trench drain grates, making them an essential component for effective drainage solutions.

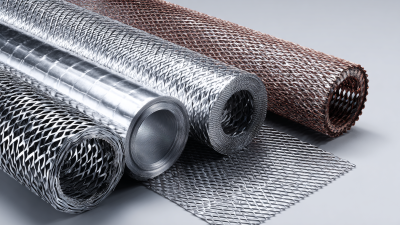

Different Materials Used in Trench Drain Grates and Their Benefits

Trench drain grates play a crucial role in maintaining optimal drainage performance, and their material composition significantly affects their efficiency and durability. Common materials used for trench drain grates include stainless steel, plastic, and cast iron. Stainless steel offers a sleek appearance and exceptional resistance to rust and corrosion, making it ideal for outdoor applications where weather impact is a concern. On the other hand, plastic grates are lightweight and highly resistant to chemicals, allowing for easy installation and maintenance in various environments.

When it comes to cast iron, its strength and longevity make it suitable for heavy load applications, such as roadways or industrial areas. However, it is essential to consider the weight of the grate, as heavier grates may require more robust supporting structures. Each material provides unique benefits, so choosing the right one depends on the specific needs of your drainage project.

**Tip:** For residential projects, consider using stainless steel or plastic grates, as they typically require less maintenance and are more aesthetically pleasing. If you’re working in high-traffic areas, opt for cast iron to ensure maximum durability. Always consult with a specialist to determine the best material suited for your particular drainage needs.

How Trench Drain Grates Contribute to Effective Water Management

Trench drain grates play a vital role in effective water management by facilitating the swift collection and transportation of surface water. These functional components are designed to cover trench drains, which are essentially narrow channels installed in various settings, from commercial properties to residential driveways. The grates allow water to flow into the trench without obstructing passing vehicles or pedestrians, ensuring a seamless integration into the surrounding environment. By capturing runoff during rain events, trench drain grates help prevent flooding and erosion, thereby maintaining the integrity of landscapes and structures.

Moreover, the materials and designs of trench drain grates significantly influence their performance. Options such as metal, plastic, or concrete provide different levels of strength and corrosion resistance, catering to diverse applications. Many grates also come with safety features, such as slip-resistant surfaces, to enhance user safety. Through their strategic placement in high-water areas, these grates not only manage water effectively but also contribute to the overall efficiency of drainage systems, reducing maintenance costs, and promoting sustainable water management practices in urban planning.

Selecting the Right Trench Drain Grate for Your Specific Needs

When selecting the right trench drain grate for your specific needs, it's essential to consider a variety of factors, including size, material, and load capacity. The size of the grate must correspond to the trench dimensions to ensure proper fit and optimal water flow. Additionally, the spacing and design of the grate openings should be tailored to effectively handle the anticipated volume of runoff while preventing debris from clogging the system.

Material choice also plays a significant role in performance and longevity. Common materials include polymer, stainless steel, and cast iron, each offering different levels of durability and resistance to environmental factors. For instance, stainless steel grates provide excellent rust resistance and strength, making them ideal for high-load areas. In contrast, polymer grates may be lighter and easier to install, suitable for low-traffic residential applications. Ultimately, understanding the specific drainage requirements and environmental conditions of your project will guide you in selecting the most appropriate trench drain grate for efficient water management.

Related Posts

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

-

Unlocking Strength: How Steel Mesh Reinforces Modern Construction Trends with 30% Increased Durability

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Understanding the Importance of Stair Nosings for Safety and Aesthetics in Your Home