Top 10 Steel Stair Treads for Safety and Durability You Need to Know About

In the construction and safety industry, the importance of choosing the right materials cannot be overstated. Steel stair treads have emerged as a crucial element in enhancing both safety and durability in various environments. Renowned expert in construction safety, Dr. James Thornton, emphasizes, "The proper selection of steel stair treads can significantly reduce the risk of accidents while ensuring the longevity of the structure." This highlights the vital role that these components play in maintaining safety standards while providing durable solutions for both commercial and residential applications.

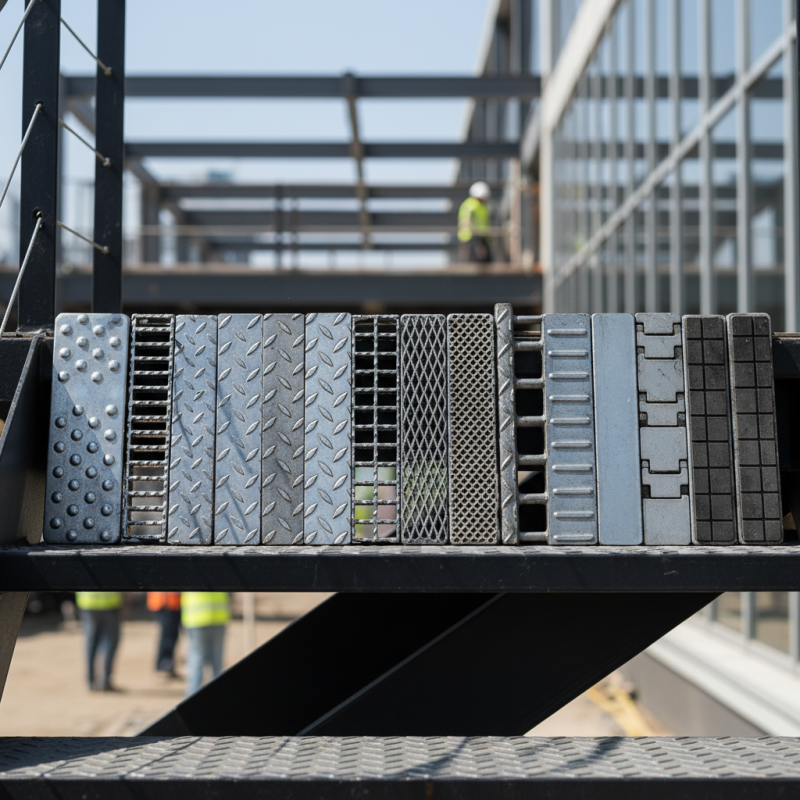

As we delve into the top 10 steel stair treads available in the market, it is essential to understand the unique features that make each option suitable for specific environments. From slip-resistant surfaces to robust materials, these stair treads are designed to withstand heavy foot traffic and adverse weather conditions. By selecting the right type of steel stair treads, one can not only improve safety but also add value to their property through enhanced aesthetic appeal and functionality.

In this article, we will explore various types of steel stair treads, their applications, and what to consider when making a choice. Understanding these factors will empower builders, architects, and homeowners alike to make informed decisions that prioritize safety and durability. Join us as we outline the essential features and benefits of the top steel stair treads available today.

What Are Steel Stair Treads and Their Importance in Safety?

Steel stair treads are essential components in architectural safety, designed to enhance both durability and traction in high-traffic areas. These treads are typically fabricated with non-slip surfaces which provide additional grip for individuals navigating staircases, significantly reducing the risk of slips and falls. According to the National Safety Council, slips and falls account for nearly 25% of all reported injury claims each year, emphasizing the critical role that effective stair design plays in preventing workplace accidents and promoting general safety.

The importance of steel stair treads extends beyond mere safety; they also contribute to overall durability in various environments. Research from the American National Standards Institute indicates that steel structures outperform other materials in terms of longevity and maintenance. Corrosion-resistant coatings further enhance the lifespan of steel treads, making them suitable for both indoor and outdoor applications, even in adverse weather conditions. This durability not only saves costs related to repairs and replacements but also ensures a consistently safe environment over time. Implementing steel stair treads effectively aligns with safety regulations and standards, underscoring their necessity in constructing safe operational spaces.

Key Features to Consider When Choosing Steel Stair Treads

When choosing steel stair treads, several key features should be carefully considered to ensure both safety and durability. Firstly, the material's slip resistance is critical. According to industry reports, approximately 28% of all workplace accidents are caused by slips, trips, and falls. Opting for tread designs that incorporate textured surfaces or coatings can significantly reduce these incidents. Look for options that feature a high coefficient of friction, ideally meeting or exceeding the American National Standards Institute (ANSI) recommendations.

Another important factor is the tread's load capacity. Steel stair treads are often subjected to heavy foot traffic and potential impacts. Selecting treads that are engineered to support substantial weight—often tested with a load capacity of 1,500 lbs or more—ensures that they can withstand daily use without compromising structural integrity. Additionally, consider corrosion resistance; treads made with galvanized or stainless steel can prevent degradation from environmental factors, extending their lifespan and maintaining safety.

**Tips**: Always consult with safety auditors or building codes to ensure compliance with local regulations when installing stair treads. Regular maintenance checks can help identify any wear or damage early, prolonging the lifespan of your steel treads. Lastly, investing in anti-slip additives or taping can provide an extra layer of safety, especially in high-traffic or outdoor environments.

Top 10 Steel Stair Treads for Safety and Durability You Need to Know About

| Model | Material | Dimensions | Surface Type | Weight Capacity | Slip Resistance Rating | Warranty |

|---|---|---|---|---|---|---|

| Model A | Steel | 12" x 36" | Textured | 1000 lbs | ASTM C1028 | 5 years |

| Model B | Galvanized Steel | 10" x 40" | Non-Slip | 1200 lbs | R11 | 10 years |

| Model C | Stainless Steel | 14" x 36" | Grippable | 1500 lbs | ASTM C1028 | Lifetime |

| Model D | Carbon Steel | 12" x 30" | Diamond Plate | 900 lbs | R9 | 3 years |

| Model E | Powder-Coated Steel | 16" x 40" | Grip Surface | 1300 lbs | R12 | 7 years |

Top 10 Steel Stair Treads: A Comprehensive Review

When it comes to ensuring safety in both residential and commercial settings, choosing the right steel stair treads is paramount. Steel treads offer immense durability and are designed to withstand heavy foot traffic, making them ideal for industrial environments. According to a recent report by the Occupational Safety and Health Administration (OSHA), falls are among the leading causes of workplace injuries, emphasizing the need for effective safety solutions like stair treads. For instance, steel treads often feature anti-slip surfaces, which can reduce slip and fall incidents by up to 50%, significantly enhancing safety measures.

In addition to safety, the longevity of steel stair treads makes them a smart investment. A study by the American National Standards Institute (ANSI) indicates that materials properly treated for corrosion resistance can last up to 30 years in outdoor environments. Furthermore, their ability to withstand extreme weather conditions without compromising structural integrity adds to their appeal in various settings, from factory floors to outdoor steps. By considering factors such as tread thickness, surface texture, and load rating, users can select the most suitable steel treads that align with performance standards while ensuring safety and longevity for all users.

Maintenance Tips for Ensuring Durability of Steel Stair Treads

Maintaining the durability of steel stair treads is essential to ensure safety and longevity. Regular cleaning is an integral part of this maintenance routine. Dirt, grime, and moisture can lead to corrosion over time, so it's important to sweep and wash the treads periodically using non-corrosive cleaners. For tougher stains or substances such as grease, using a mild detergent can effectively remove them without damaging the surface. Additionally, inspecting for any signs of wear, such as rust spots or dents, should be conducted routinely to address potential issues before they escalate.

Another crucial aspect of maintenance is applying a protective coating. Depending on the environment in which the stair treads are used, a sealant or anti-slip coating can enhance their durability and safety. This preventative measure not only helps in minimizing corrosion but also increases traction, especially in wet or icy conditions. Furthermore, consider implementing an inspection schedule to assess the integrity of the treads regularly, ensuring that any necessary repairs or replacements can be made promptly. By following these maintenance tips, the lifespan of steel stair treads can be significantly extended, providing a safe and reliable surface for all users.

Top 10 Steel Stair Treads Durability Ratings

The chart below illustrates the durability ratings of different steel stair treads based on material properties and user feedback. The ratings are based on a scale of 1 to 10, where 10 indicates maximum durability.

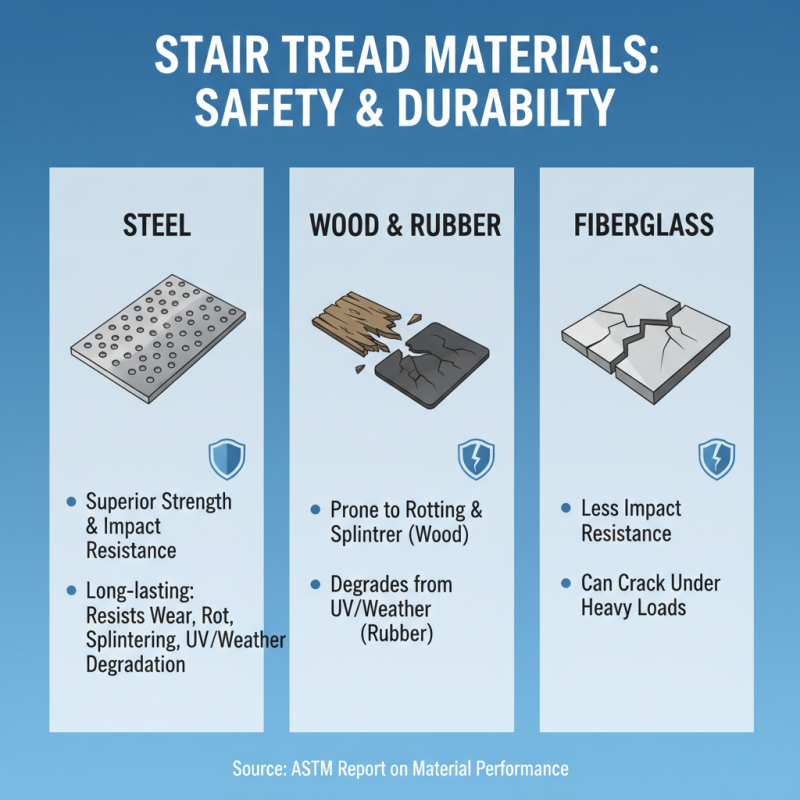

Comparing Steel Stair Treads to Other Materials: Pros and Cons

When it comes to choosing materials for stair treads, steel stands out due to its superior safety and durability compared to other common options like wood, rubber, or fiberglass. According to a report by the American Society for Testing and Materials (ASTM), steel treads can withstand significant weight and impact, making them ideal for high-traffic areas in both commercial and industrial settings. Steel's inherent strength allows it to resist wear and tear much longer than wood, which is more prone to rotting and splintering, and rubber, which may degrade over time when exposed to UV light and harsh weather conditions.

Moreover, the slip-resistance of steel treads is another critical advantage. Industry studies indicate that the use of textured steel surfaces can significantly reduce the risk of slips and falls, particularly in wet or oily environments. Unlike fiberglass, which may offer some slip resistance but lacks the overall strength and longevity of steel, steel treads provide a reliable, long-lasting solution. While the initial cost of steel treads may be higher than alternatives, their lifespan and performance under demanding conditions often make them the more economical choice in the long run.

Related Posts

-

Enhancing Safety and Style: The Ultimate Guide to Choosing Steel Stair Treads for Your Home

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

Understanding the Importance of Stair Nosings for Safety and Aesthetics in Your Home

-

What is a Trench Drain Grate and How It Ensures Optimal Drainage Performance

-

Understanding the Benefits of Aco Drain Systems for Modern Drainage Solutions

-

2025 How to Choose the Best Aluminum Stair Treads for Safety and Durability