What is Stainless Steel Mesh Screen? Exploring Benefits, Applications, and Market Trends in 2023

In the evolving landscape of industrial materials, the stainless steel mesh screen has emerged as a crucial component across various sectors, including construction, manufacturing, and food processing. As the global market for stainless steel mesh is projected to reach USD 3.5 billion by 2025, according to a recent report by Grand View Research, it is essential to understand the extensive benefits and applications of this versatile product. The robust nature of stainless steel mesh provides not only durability and strength but also resistance to corrosion and high temperatures, making it ideal for demanding environments.

Industry expert Dr. John Carter, a leading authority in materials science, emphasizes the significance of stainless steel mesh screens in modern applications, stating, "The versatility and reliability of stainless steel mesh screens are unparalleled, enabling a wide array of solutions that meet stringent industry standards." As we explore the trends shaping this market in 2023, from advancements in manufacturing techniques to innovations in design, it is clear that the demand for stainless steel mesh screens continues to grow, driven by their essential role in enhancing operational efficiency and safety across multiple industries.

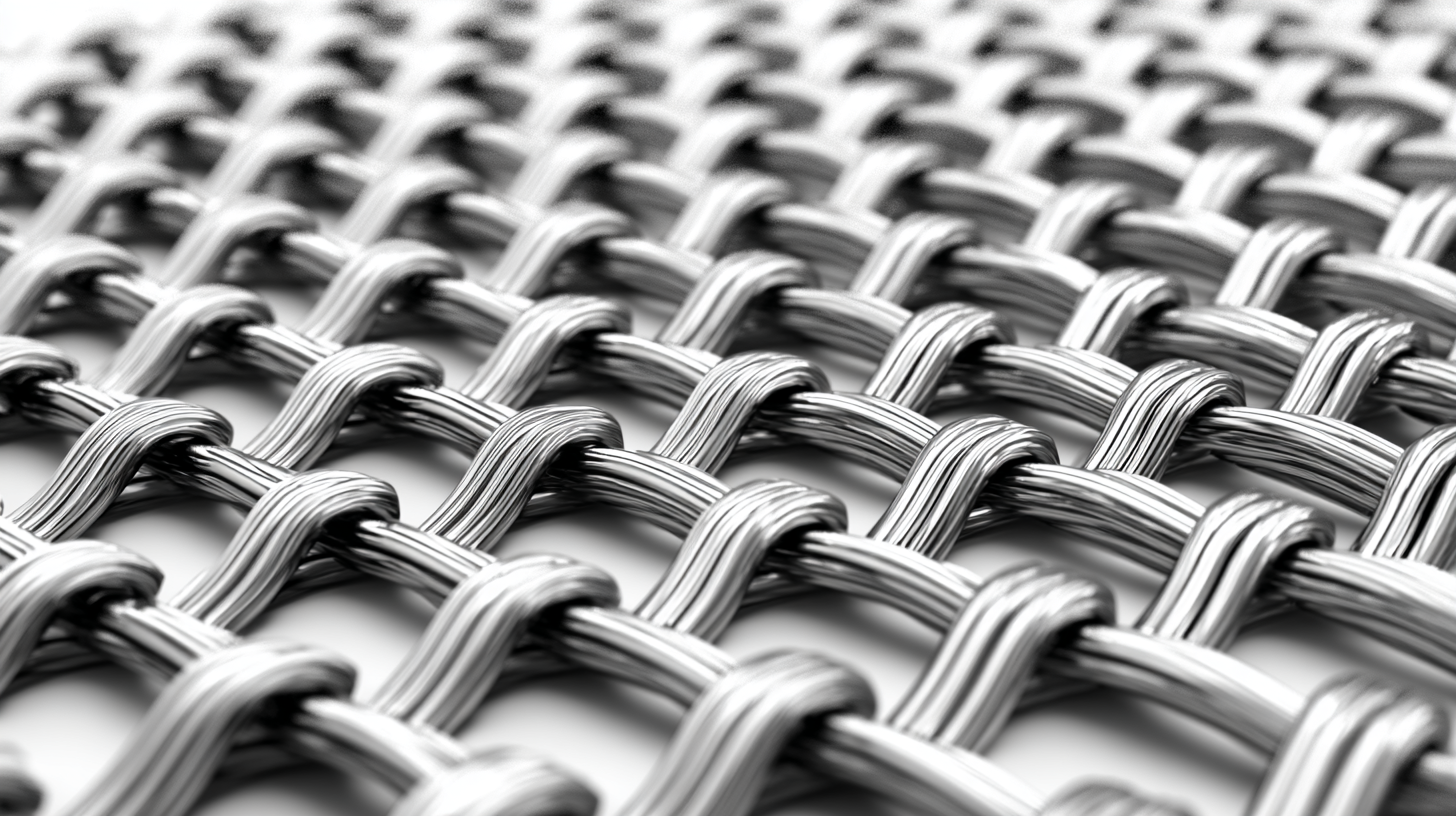

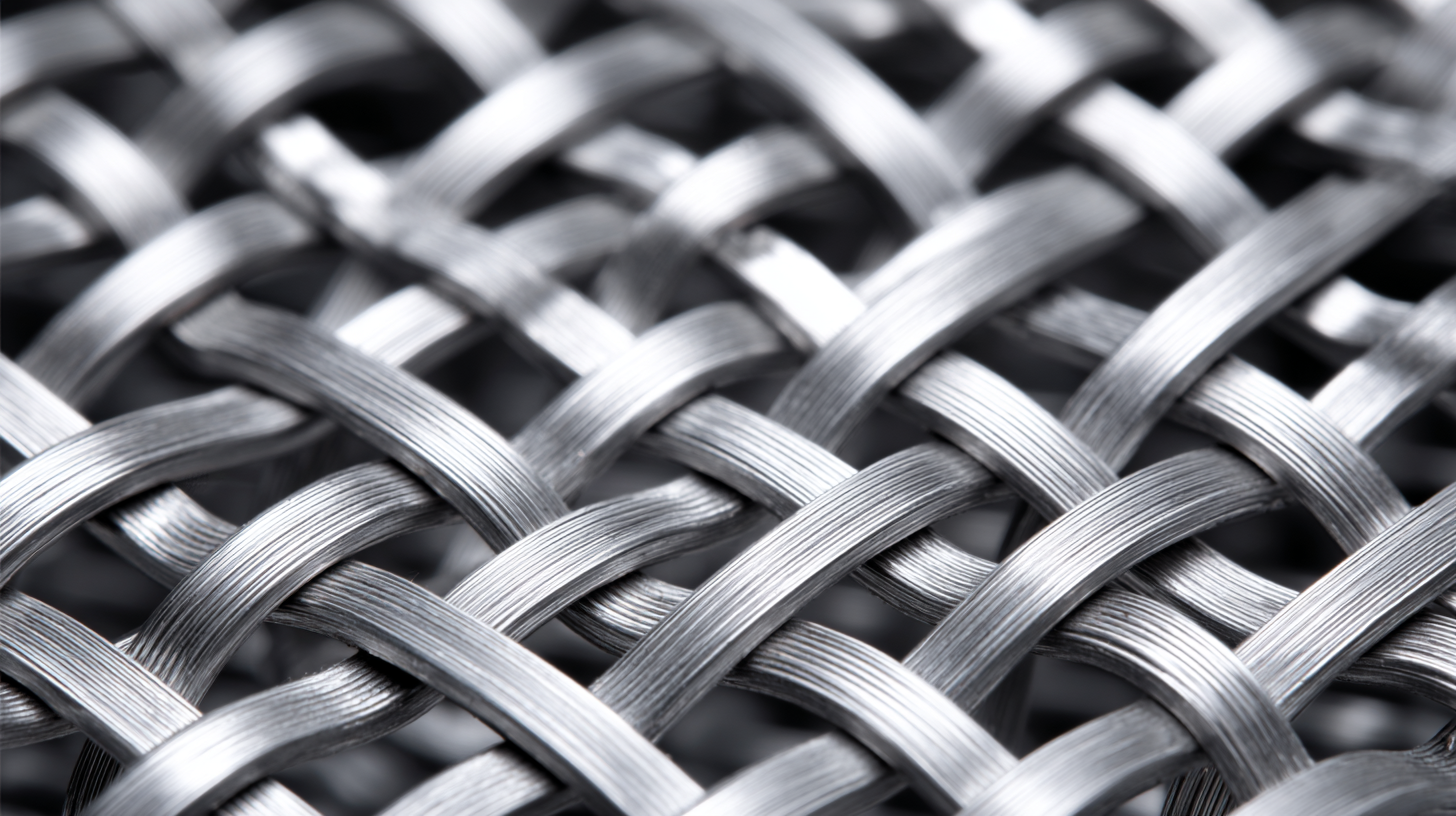

Definition and Characteristics of Stainless Steel Mesh Screen

Stainless steel mesh screens are versatile materials characterized by their woven construction, which offers strength and durability. These screens are made from stainless steel wires that are interlaced to form a mesh pattern, providing not only structural integrity but also resistance to corrosion and rust. This makes them ideal for use in various environments, including those exposed to moisture and harsh conditions. The properties of stainless steel—such as its aesthetic appeal and low maintenance needs—further enhance its popularity in both residential and industrial applications.

The application of stainless steel mesh screens is diverse, extending from architectural uses to filtration systems. In modern home design, architects and interior designers have embraced stainless steel mesh for its ability to create stylish partitions while also allowing light and air to flow through. Furthermore, industries utilize stainless steel mesh screens in processes like food processing, pharmaceuticals, and water filtration, where hygiene and durability are paramount. As trends in eco-friendly and sustainable practices continue to rise, the demand for materials like stainless steel mesh is expected to grow, reflecting a shift towards more enduring and resilient building practices.

Advantages of Using Stainless Steel Mesh Screen in Various Industries

Stainless steel mesh screens have gained immense popularity across various industries due to their remarkable advantages. One of the primary benefits is their durability; stainless steel is highly resistant to corrosion, rust, and wear, making it ideal for use in challenging environments. This longevity significantly reduces maintenance costs and replacement frequency, allowing businesses to allocate resources more efficiently. Furthermore, the high tensile strength of stainless steel mesh ensures that it can withstand heavy loads and impact, enhancing safety in industrial applications.

Another notable advantage is the versatility of stainless steel mesh screens. They find applications in filtration, security, and architectural design, among others. In the food and beverage sector, stainless steel mesh is used for filtration processes, ensuring hygiene and preventing contamination. Meanwhile, in construction, it serves both functional and aesthetic purposes, offering robust security while maintaining an appealing look. As industries increasingly focus on sustainability, the recyclability of stainless steel presents an additional incentive, aligning with modern environmental standards and practices.

What is Stainless Steel Mesh Screen? Exploring Benefits, Applications, and Market Trends in 2023

| Application | Industry | Benefits | Market Trend (2023) |

|---|---|---|---|

| Filtration | Food Processing | Corrosion Resistance, Durable | Increasing demand for food safety |

| Caging and Fencing | Agriculture | Weather Resistant, Low Maintenance | Growth in organic farming |

| Architectural Features | Construction | Aesthetic Appeal, Customization | Rising interest in sustainable designs |

| Screening | Mining | High Strength, Versatility | Increased mineral extraction activities |

| Safety Gratings | Industrial | Slip Resistance, Long Lifespan | Growing focus on workplace safety |

Common Applications of Stainless Steel Mesh Screen in 2023

Stainless steel mesh screens have become essential in various industries due to their durability and versatility. In 2023, they are primarily utilized in filtration systems, architectural applications, and safety barriers.

The fine mesh structure effectively filters liquids and gases, making it invaluable in the food processing and pharmaceutical sectors. Additionally, the aesthetic quality of stainless steel makes it a popular choice for decorative elements in modern architecture.

Stainless steel mesh screens have become essential in various industries due to their durability and versatility. In 2023, they are primarily utilized in filtration systems, architectural applications, and safety barriers.

The fine mesh structure effectively filters liquids and gases, making it invaluable in the food processing and pharmaceutical sectors. Additionally, the aesthetic quality of stainless steel makes it a popular choice for decorative elements in modern architecture.

When deploying stainless steel mesh screens, consider these tips: ensure the right mesh size for your specific filtration needs, and choose a grade of stainless steel that can withstand the environmental conditions of your application.

Regular maintenance is also key to preserving the integrity of the mesh, especially in corrosive environments.

Another common application in 2023 is in the construction industry, where stainless steel mesh is used for reinforcing concrete and supporting structures. Its strength and resistance to corrosion make it ideal for use in exposed environments.

Furthermore, stainless steel mesh is also gaining traction in the realm of insect screens for homes and buildings, offering a durable solution that combines functionality with appealing aesthetics.

Current Market Trends and Future Projections for Stainless Steel Mesh Screen

The global stainless steel mesh screen market is experiencing significant growth, driven by its versatile applications across various industries. According to a recent report by Market Research Future, the market is projected to reach USD 1.5 billion by 2028, expanding at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2028. This growth can be attributed to the increasing demand for corrosion-resistant, durable materials in sectors like construction, food and beverage, and automotive.

In 2023, key trends include innovation in manufacturing techniques and designs, which enhance the performance and versatility of stainless steel mesh screens. The incorporation of advanced technologies such as automation and the development of customized solutions are making these products more efficient and cost-effective. Additionally, sustainability considerations are influencing purchasing decisions, as industries move towards more environmentally friendly materials. According to the Stainless Steel Research Institute, over 60% of consumers prioritize sustainability when choosing industrial supplies, indicating a paradigm shift in market dynamics.

Comparison of Stainless Steel Mesh Screen with Other Types of Mesh Screens

When discussing mesh screens, stainless steel mesh screens stand out due to their unique properties and benefits. Unlike traditional wire or plastic mesh screens, stainless steel offers superior strength, durability, and resistance to corrosion and rust. This makes them an excellent choice for various applications, especially in environments prone to moisture or chemicals. Furthermore, stainless steel mesh screens can endure high temperatures, making them suitable for use in industrial settings and kitchen applications.

Tip: When selecting a mesh screen, consider the environment in which it will be used. For high humidity or corrosive areas, stainless steel is often the best option to ensure longevity and maintain performance.

In contrast, other types of mesh screens, such as aluminum or fiberglass, may be lightweight and cost-effective but lack the robustness and lifespan of stainless steel. Aluminum can corrode over time, especially in harsh weather conditions, while fiberglass, although resistant to chemicals, is not as durable under high-stress applications. Investing in stainless steel mesh screens often proves to be more economical in the long run due to their extended service life.

Tip: Evaluate the specific requirements of your project before choosing your mesh type—think about factors like environmental exposure, weight considerations, and long-term costs.

Related Posts

-

The Ultimate Guide to Choosing the Right Stainless Steel Mesh Screen for Your Home Projects

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

Understanding the Benefits of Using Steel Stair Treads in High Traffic Areas

-

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights