What is Perforated Metal? Exploring Uses, Benefits, and Design Options

Perforated metal is an incredibly versatile material that has found its way into a myriad of applications across various industries. Characterized by its unique pattern of holes and openings, perforated metal not only serves functional purposes but also enhances aesthetic appeal. From architecture to automotive design, the uses of perforated metal are vast, making it a popular choice among designers and engineers alike.

The benefits of perforated metal extend beyond mere functionality. Its lightweight nature, durability, and ability to facilitate airflow while providing structural support make it an ideal material for projects ranging from acoustic panels to filtration systems. Designers appreciate the freedom perforated metal offers in terms of customization, as it can be tailored to meet specific design needs and preferences. This flexibility allows for innovative and creative uses that push the boundaries of traditional materials.

In exploring the world of perforated metal, one can appreciate its significance in modern design and engineering, as well as the endless possibilities it presents. Whether one is interested in its practical applications or its design options, understanding perforated metal is essential for anyone looking to leverage its many advantages in their projects.

Definition of Perforated Metal: Characteristics and Composition

Perforated metal is defined as a versatile material that features a series of holes or openings manufactured through processes such as punching or drilling. The composition of perforated metal typically consists of various metals, including stainless steel, aluminum, and carbon steel, each offering distinct characteristics that cater to specific applications. The physical properties of the material—such as durability, lightness, and resistance to corrosion—make it suitable for use in diverse industries from construction and architecture to filtration and automotive applications. According to industry reports, the global perforated metal market was valued at approximately USD 1.5 billion in 2022 and is projected to grow significantly, driven by increased demand in industrial applications.

When considering design options, perforated metal can be customized according to hole size, pattern, and thickness, allowing for endless possibilities in terms of aesthetics and function. For example, larger holes can provide greater airflow and light passage, while smaller holes may be better suited for filtration purposes. The Eco-Business Report has indicated that the incorporation of perforated metal in building design not only enhances visual appeal but also contributes to energy efficiency, further highlighting its multifunctionality.

Tips: When selecting perforated metal for your project, consider not only the appearance but also the functionality, such as the intended use of the material. Collaborating with a professional can help ensure that the specifications meet both aesthetic and performance requirements. Additionally, keep in mind that the choice of metal will impact the longevity and maintenance of the product; selecting a corrosion-resistant option may be beneficial in environments exposed to moisture.

Common Manufacturing Processes for Perforated Metal

Perforated metal, characterized by its precise holes and patterns, is manufactured through several techniques tailored to meet diverse application needs. The most common manufacturing processes include punch pressing, laser cutting, and CNC machining. Punch pressing is often favored for its cost-effectiveness and efficiency in producing high volumes of metal sheets with consistent hole shapes. According to a report by the Industrial Fabricators Association, this method can achieve punch rates of 800 to 1000 strokes per minute, significantly enhancing production times while maintaining design accuracy.

Laser cutting has also gained popularity, particularly for applications requiring intricate patterns and precise dimensions. This method employs a high-powered laser to vaporize material, allowing for more complex designs that are often unachievable through conventional punching. A study from the Metalworking Research Institute highlights that laser cutting can reduce the thermal distortion of the material, thus preserving its structural integrity, which is crucial for industries like aerospace and automotive where standards are stringent.

CNC (Computer Numerical Control) machining represents a more advanced approach, delivering exceptional customization capabilities for perforated metal products. This method allows for real-time adjustments during the manufacturing process, facilitating the production of bespoke designs tailored to specific customer requirements. The flexibility of CNC machining is reflected in recent data from the Manufacturing Technology Association, which indicates a 35% increase in CNC applications for perforated metal in the last five years, underscoring its growing relevance in modern manufacturing.

What is Perforated Metal? Exploring Uses, Benefits, and Design Options - Common Manufacturing Processes for Perforated Metal

| Use Case | Benefits | Design Options | Common Manufacturing Processes |

|---|---|---|---|

| Architectural Facades | Aesthetic appeal, ventilation | Patterns, hole sizes, material finishes | Laser cutting, stamping |

| Noise Control Panels | Sound absorption, privacy | Custom shapes, varying perforation patterns | Punching, CNC machining |

| Security Screens | Increased safety, visibility | Multiple panel designs, color options | Hydraulic punching, machining |

| Industrial Applications | Durability, functionality | Thickness, hole pattern density | Perforating, rolling |

| Filter Elements | Efficient fluid flow, filtration | Custom perforation sizes, layered structures | Stamping, welding |

Diverse Applications of Perforated Metal in Various Industries

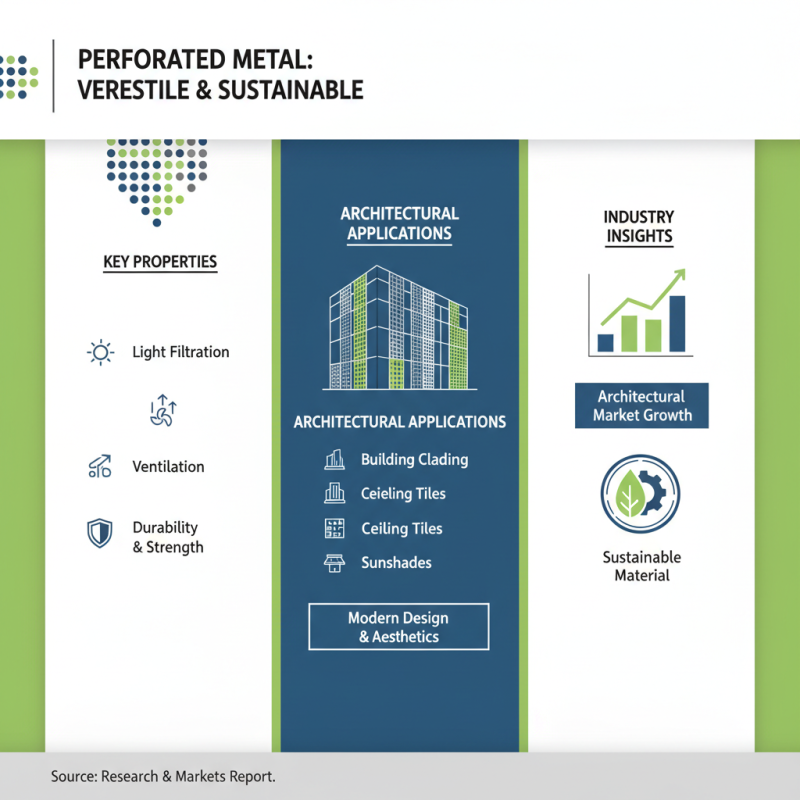

Perforated metal is a versatile material widely utilized across various industries due to its unique properties and functionalities. In architectural applications, for instance, perforated metal panels serve both aesthetic and practical purposes. According to a report by Research and Markets, the architectural segment is projected to grow significantly, with an increasing demand for sustainable building materials. Perforated metal allows for light filtration and ventilation while contributing to modern design aesthetics, making it an ideal choice for cladding, ceiling tiles, and sunshades.

In the manufacturing sector, the use of perforated metal is critical for processes involving filtration and separation. The global market for filtration is expected to reach USD 59.33 billion by 2025, according to a study by Grand View Research. Perforated metal sheets are employed in machinery, automotive, and food processing industries for screen applications, ensuring efficient fluid flow and preventing material contamination. Additionally, the customization options available with perforated metal—such as hole size, pattern, and thickness—allow for tailored solutions that meet specific operational needs across diverse sectors. This adaptability further cements perforated metal's status as a key component in modern industrial practices.

Advantages of Using Perforated Metal in Design and Functionality

Perforated metal has gained popularity in various design and architectural applications due to its unique combination of aesthetic appeal and functionality. The advantages of using perforated metal are manifold. Primarily, it offers excellent light and air permeability, making it ideal for environments where ventilation is essential. This feature not only enhances the comfort of spaces but also contributes to energy efficiency by reducing reliance on mechanical heating or cooling systems.

Moreover, perforated metal allows for creative design possibilities. Its patterns can be tailored to suit specific aesthetic needs while maintaining structural integrity. Designers can incorporate various hole sizes, shapes, and arrangements, enabling them to achieve intricate visuals that can transform any project. Additionally, this material can be utilized in diverse settings, from architectural facades and shading devices to decorative interior elements.

Tips for selecting perforated metal include considering the application environment, as materials can vary dramatically in terms of corrosion resistance and strength. It’s also beneficial to visualize how different patterns will interact with light and shadows before finalizing designs. Always consult with professionals to ensure that the chosen perforated metal will meet both design and functional requirements effectively.

Advantages of Using Perforated Metal in Design and Functionality

Design Options and Customization Potential for Perforated Metal Products

Perforated metal, a versatile and functional material, offers a myriad of design options and customization potential that caters to various industries. One of the most compelling aspects of perforated metal is its ability to be tailored to meet specific aesthetic and functional requirements. According to a report by Grand View Research, the global perforated metal market size was valued at approximately USD 2.05 billion in 2020 and is projected to expand at a CAGR of 4.3% from 2021 to 2028. This growth underscores the increasing demand for custom-designed perforated products in architecture, filtration, and industrial applications.

The customization potential of perforated metal products lies in the variety of hole patterns, sizes, and sheet thicknesses available. Designers can choose from a range of hole shapes—round, square, or even custom shapes—to create unique visual effects or optimize functionality for specific uses, such as sound dampening or ventilation. The ability to modify the percentage of open area in the perforation also allows for adjustments in airflow, light penetration, and aesthetic appeal. Industry data indicates that around 60% of perforated metal applications are in the architectural sector, including facades, signage, and interior design elements, highlighting the material's adaptability and relevance in modern design trends.

Additionally, advancements in laser cutting and CNC technology further enhance the customization capabilities of perforated metal, enabling more intricate designs while maintaining cost-effectiveness and efficiency in production. As industries continue to seek innovative materials that combine durability with design flexibility, perforated metal is positioned as a prime choice for both functional and creative applications.

Related Posts

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Unlocking Strength: How Steel Mesh Reinforces Modern Construction Trends with 30% Increased Durability

-

Why Metal Mesh Screens Are Essential for Your Home and Business Needs

-

What is a Perforated Metal Sheet? A Comprehensive Guide to Its Uses and Benefits

-

What is Perforated Metal and Its Uses in Construction and Design

-

Top 10 Steel Stair Treads for Safety and Durability You Need to Know About