What is a Perforated Metal Sheet? A Comprehensive Guide to Its Uses and Benefits

Perforated metal sheets have gained significant traction across various industries due to their unique combination of functionality and aesthetics. According to a recent report by Grand View Research, the global perforated metal market is projected to reach over $3 billion by 2025, driven by rising demand in sectors such as architecture, automotive, and filtration. As industries seek innovative materials that offer mechanical strength along with lightweight properties, perforated metal sheets emerge as an optimal choice.

Industry expert Dr. John Smith, a leading material scientist at the Institute of Advanced Manufacturing, emphasizes the versatility of these materials, stating, "Perforated metal sheets not only enhance physical performance but also provide opportunities for creative design applications that traditional materials cannot match." This statement encapsulates the essence of why perforated metal sheets are increasingly being integrated into both functional and decorative applications, from building façades to noise reduction panels.

In this comprehensive guide, we will delve into the uses and benefits of perforated metal sheets, exploring their advantages in various sectors and highlighting the innovative designs that have evolved due to their implementation. By understanding the characteristics and potential of perforated metal, we can appreciate its pivotal role in shaping modern engineering and architectural solutions.

Understanding Perforated Metal Sheets: Definition and Composition

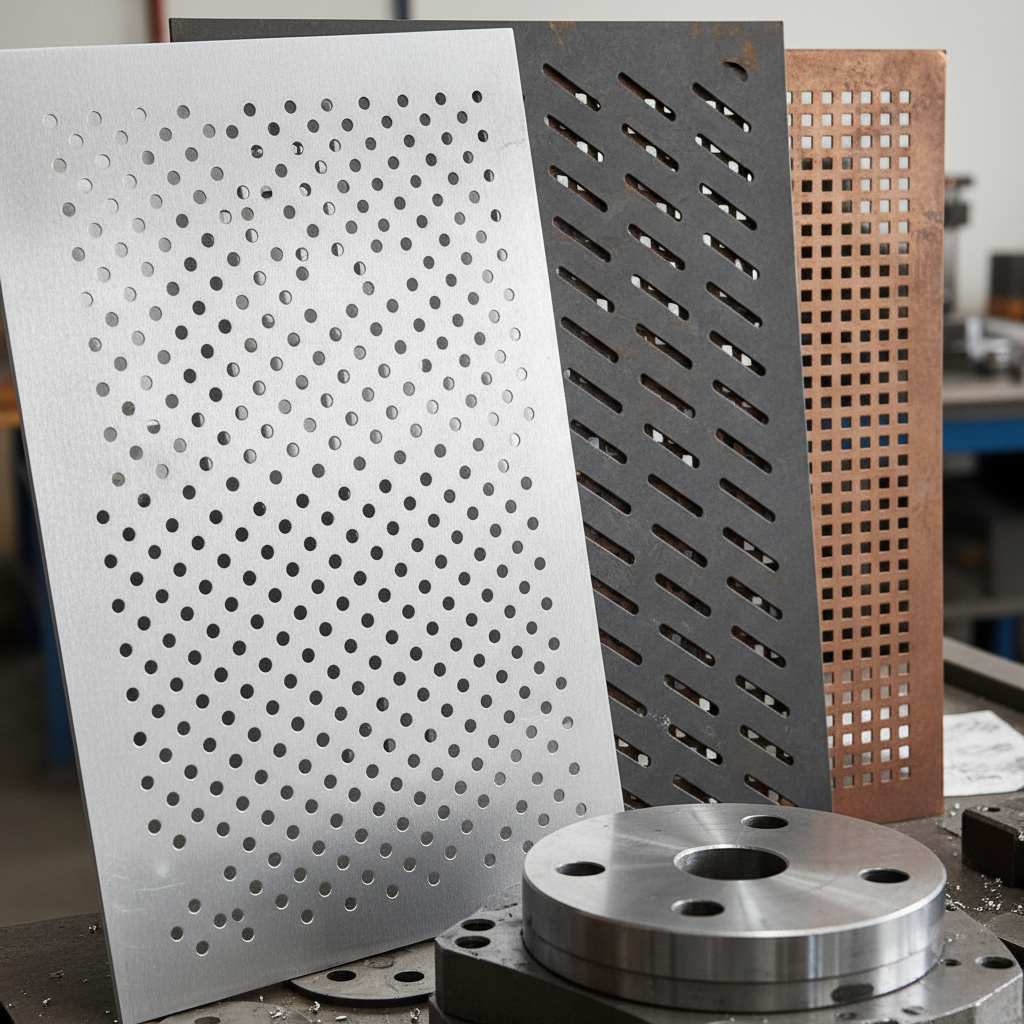

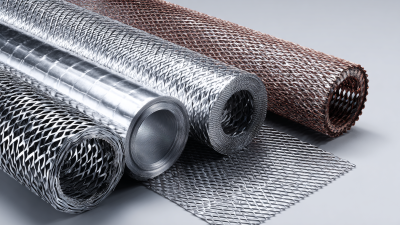

Perforated metal sheets are a versatile and functional material that have gained prominence across various industries. Defined by their distinctive patterns of holes, these sheets are typically made from various metals, including stainless steel, aluminum, and mild steel. The holes can be round, square, or custom shapes, allowing for a range of designs suitable for specific applications. The composition of a perforated metal sheet contributes greatly to its strength, lightweight nature, and suitability for different environments, making it a popular choice for architectural and industrial purposes.

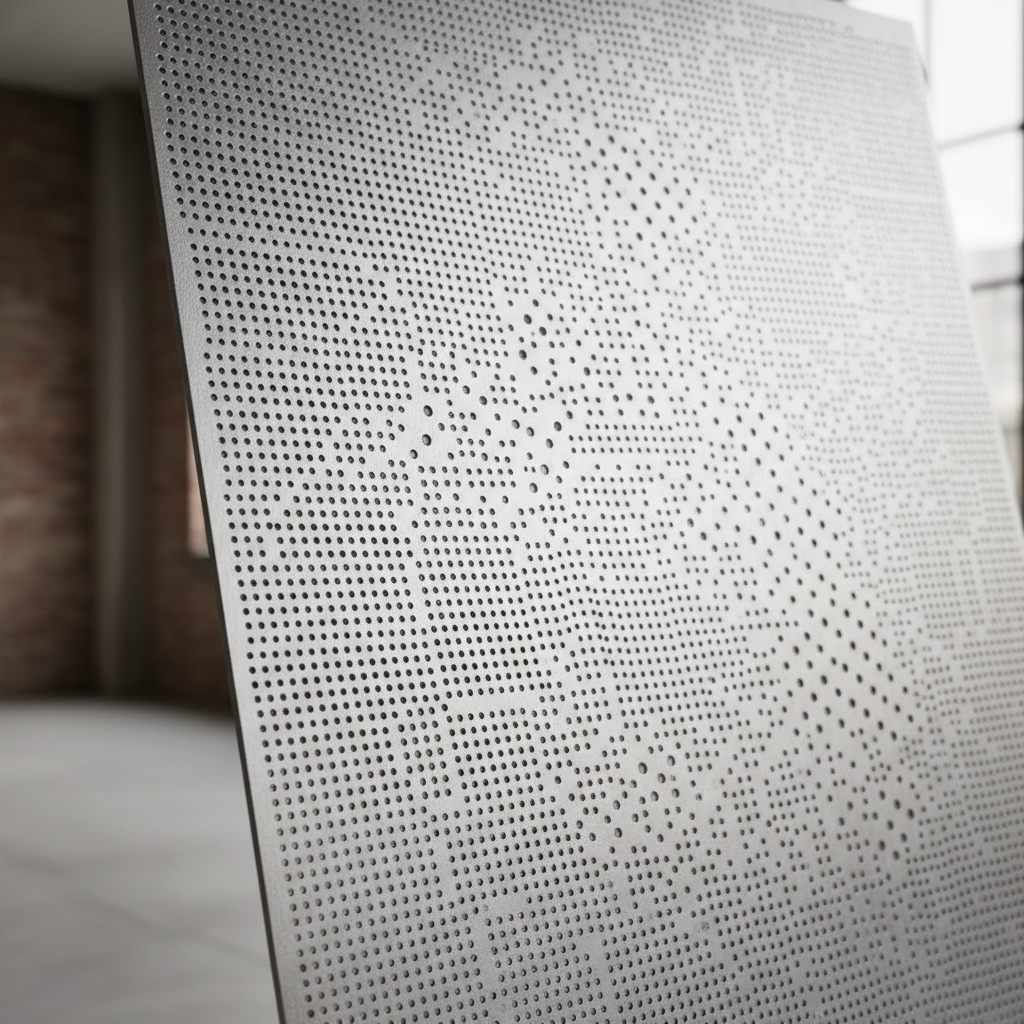

The manufacturing process of perforated metal sheets involves precise techniques that ensure the holes are consistently shaped and distributed. This not only impacts the aesthetic appeal of the product but also enhances its functionality. For instance, the perforation allows for optimal airflow, sound attenuation, and even light filtration, making these sheets ideal for acoustic panels, ceilings, and facades. Additionally, their customizable nature means they can be tailored to meet the specific needs of a project, whether for decorative purposes or structural applications. As industries continue to evolve, the applications of perforated metal sheets are becoming increasingly innovative, showcasing their importance in modern design and engineering.

Common Manufacturing Techniques for Perforated Metal Sheets

Perforated metal sheets are created through various manufacturing techniques that ensure precision and functionality. One of the most common methods is mechanical punching, where a die is used to create holes in the metal sheet under high pressure. This technique allows for a high degree of customization in terms of hole size, pattern, and spacing, making it suitable for diverse applications, from architectural designs to filtration systems.

Another popular method is laser cutting, which employs a focused beam of light to achieve intricate hole patterns with exceptional accuracy. Laser cutting is particularly advantageous for projects requiring complex geometries or fine details, as it minimizes material waste and can be quickly adjusted for different designs. Additionally, water jet cutting is employed to perforate metal sheets using a high-pressure stream of water mixed with abrasives, offering versatility in materials that can be processed, including thicker metal sheets, without altering their inherent properties. Each of these techniques contributes to the wide array of benefits that perforated metal sheets provide across various industries.

Diverse Applications of Perforated Metal Sheets Across Industries

Perforated metal sheets are versatile materials that find applications across a broad spectrum of industries. In the construction sector, they are commonly used for architectural panels, providing both aesthetic appeal and functional benefits such as ventilation and natural light penetration. According to a report by Research and Markets, the global architectural metal market is expected to grow significantly, with perforated sheets playing a crucial role in enhancing both the design and performance of buildings.

In the automotive industry, perforated metal sheets are employed to reduce vehicle weight while maintaining strength and safety. The lightweight characteristics are vital for improving fuel efficiency, with statistics indicating that a 10% reduction in vehicle weight can result in approximately 6-8% enhanced fuel economy. Additionally, these sheets are utilized in the manufacturing of noise and vibration damping components, evidencing their multifaceted application in improving vehicle performance and passenger comfort.

The food processing industry also benefits from perforated metal sheets, which are essential for creating filters, screens, and trays. The hygiene and cleanliness these materials offer is critical, as they can withstand high temperatures and are easy to clean. According to a report by the Food and Beverage Industry Association, the demand for innovative food processing techniques has surged, underscoring the importance of reliable materials like perforated metal sheets that can meet industry standards for safety and efficiency.

What is a Perforated Metal Sheet? A Comprehensive Guide to Its Uses and Benefits

| Application Industry | Common Uses | Material Types | Benefits |

|---|---|---|---|

| Architecture | Building facades, decorative elements | Aluminum, Steel, Stainless Steel | Aesthetic appeal, lightweight |

| Automotive | Grill designs, interior components | Steel, Aluminum | Durability, corrosion resistance |

| Food Processing | Sifting, draining applications | Stainless Steel, Food-grade materials | Hygienic, easy to clean |

| Construction | Safety barriers, ceilings | Carbon Steel, Galvanized Steel | Strength, fire resistance |

| Electronics | Speaker grilles, ventilation | Aluminum, Plastic-coated metals | Lightweight, excellent airflow |

Key Benefits of Using Perforated Metal Sheets in Design and Functionality

Perforated metal sheets are increasingly popular in various design and functional applications due to their unique blend of aesthetic appeal and practical advantages. One of the key benefits of using these sheets is their ability to enhance airflow and light penetration while maintaining structural integrity. This quality makes them ideal for architectural applications, such as facades, sunshades, and room dividers. By utilizing perforated sheets, designers can create striking visual effects while ensuring that spaces remain ventilated and illuminated.

In addition to their visual and functional benefits, perforated metal sheets are also highly versatile and customizable. They are available in a range of materials, including steel, aluminum, and copper, which can be tailored to suit specific project requirements. Furthermore, the hole pattern, size, and shape can be designed to achieve desired levels of sound absorption and aesthetic appeal. This adaptability not only allows for innovative design solutions but also ensures that such materials can meet diverse industry needs, from furniture design to industrial applications, thus broadening their appeal in numerous fields.

Factors to Consider When Choosing Perforated Metal Sheets for Projects

When selecting perforated metal sheets for projects, there are several critical factors to consider to ensure you choose the optimal material for your needs. The size, pattern, and thickness of the perforations can greatly influence performance and aesthetics. According to a report by Smithers Pira, the global market for perforated metals is projected to grow by 5.7% annually, emphasizing the rising demand for tailored solutions in various industries, including architecture and automotive.

Another crucial factor is the material composition. Steel, aluminum, and brass are common choices, each offering distinct benefits. For instance, aluminum is lightweight and corrosion-resistant, making it an excellent choice for outdoor applications. Tips: Always evaluate the environmental conditions of your project site, as the wrong material can lead to premature failure.

Additionally, consider the intended use of the perforated sheets. Whether for noise reduction, ventilation, or decorative purposes, the application will dictate necessary specifications. Investing in high-quality perforated sheets can lead to long-term cost savings, as better materials tend to require less maintenance and replacement. Tips: Consult with a supplier to discuss your specific project requirements and ensure compliance with industry standards.

Related Posts

-

2025 How to Choose the Best Aluminum Stair Treads for Safety and Durability

-

Enhancing Safety and Style: The Ultimate Guide to Choosing Steel Stair Treads for Your Home

-

Top 5 Benefits of Using Expanded Metal Sheets for Your Projects

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

Understanding the Importance of Stair Nosings for Safety and Aesthetics in Your Home

-

Understanding the Benefits of Using Steel Stair Treads in High Traffic Areas