10 Essential Tips for Choosing Stainless Steel Wire Mesh for Your Needs

Choosing the right stainless steel wire mesh can seem daunting. Many options are available, each with unique features. It is crucial to identify your specific needs before making a decision.

Evaluate the mesh size and wire gauge. These factors directly impact performance. Proper consideration can lead to better functionality in your project. Corrosion resistance is another vital aspect. Stainless steel wire mesh offers durability, but not all grades are equal.

Consider the intended application carefully. Will it be used for filtration, safety, or decoration? The answers to these questions guide your choice. Take time to reflect on your options. A hasty decision could result in unsatisfactory outcomes. In the end, a well-informed choice leads to successful use of stainless steel wire mesh.

Understanding the Different Grades of Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, understanding the different grades is crucial. Each grade offers unique properties that impact performance. For example, 304 stainless steel is common due to its excellent corrosion resistance, making it ideal for many applications. However, it may not hold up in extreme environments. The 316 grade offers better corrosion resistance, especially against chlorides. It’s often preferred for marine applications.

In a study, about 60% of users reported issues with mesh performance based on grade selection. Poor choices can lead to increased maintenance costs and reduced efficiency. Understanding tensile strength is equally important. For instance, the mesh’s wire diameter affects its load-bearing capacity. Thicker wires generally offer more strength but can reduce flexibility.

Choosing the right grade is not straightforward. It requires careful consideration of environmental factors and intended use. Many overlook heat resistance, which can affect long-term durability. Users need to reflect on their specific situations and plan accordingly.

Identifying Your Specific Wire Mesh Application Requirements

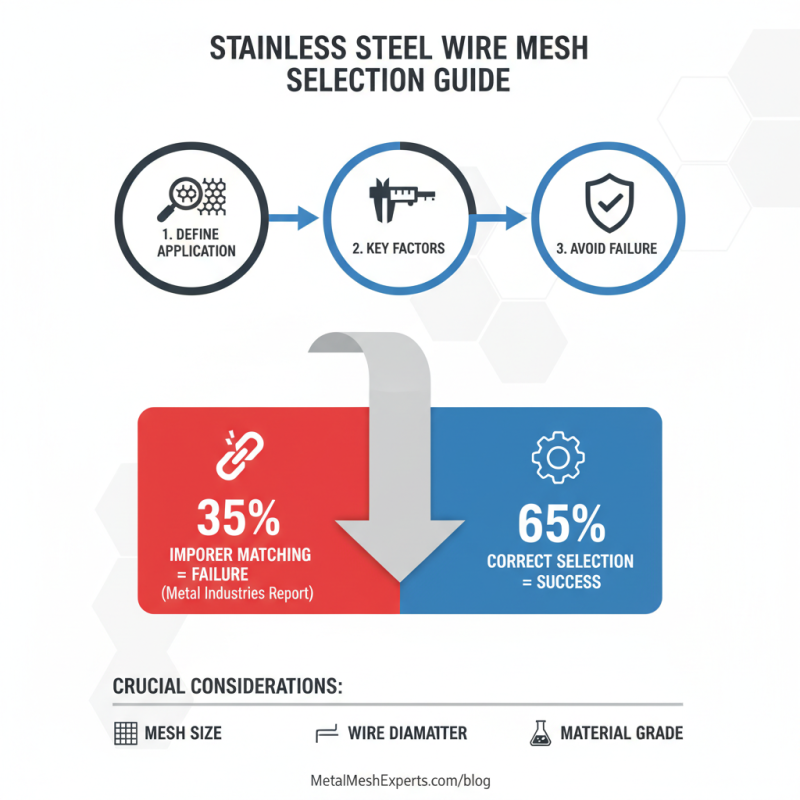

When selecting stainless steel wire mesh, understanding your specific application is crucial. Each project has unique requirements. Factors like mesh size, wire diameter, and material grade matter greatly. According to a recent report from the Metal Industries Association, around 35% of wire mesh failures stem from improper application matching.

Consider your environment. Corrosion resistance is vital if the mesh will be outdoors or in wet conditions. Different grades of stainless steel offer varying levels of strength and resistance. For example, type 304 is common but not always suitable for marine environments. Meanwhile, 316 stainless steel excels in those settings due to its added molybdenum. This highlights the need for careful selection based on location.

You should also evaluate load-bearing capacities. Inindustrial settings, heavy loads can compromise weaker mesh types. Experts suggest testing the mesh samples in the actual conditions to gauge performance. Over-reliance on standard specifications can lead to underperformance. Thus, engage engineers or specialists to ensure the mesh aligns precisely with your needs. This proactive approach minimizes costly mistakes.

Key Factors to Consider When Selecting Wire Mesh Specifications

When choosing stainless steel wire mesh, several key factors should guide your decisions. The mesh's wire diameter is essential. A thicker wire provides more durability but may also reduce flexibility. Conversely, a finer wire can offer better filtration but might be more susceptible to damage. Evaluating your specific application will help in selecting the right thickness.

Next, consider the mesh's opening size. Smaller openings are ideal for filtering particles or liquids, while larger ones allow for ventilation or structural support. Be mindful of the material's corrosion resistance as well. Different grades of stainless steel vary in their resistance to rust and chemicals. This is crucial in settings exposed to harsh environments.

Aesthetic aspects could also play a role in your selection. The finish of the mesh can impact both its appearance and functionality. It’s important to think about how it will be installed and maintained. Mistakes in these areas can lead to costly changes later. Lastly, ensure that your mesh meets any relevant regulatory standards for safety and performance. Balancing all these factors can be challenging but necessary for the best outcome.

10 Essential Tips for Choosing Stainless Steel Wire Mesh for Your Needs

| Dimension | Wire Diameter (mm) | Mesh Opening (mm) | Mesh Count | Application |

|---|---|---|---|---|

| 1/2 inch | 0.5 | 13.5 | 20 | Filtration |

| 1 inch | 1.0 | 25.4 | 18 | Security Screening |

| 2 inch | 1.5 | 50.8 | 12 | Agricultural Fencing |

| 1/4 inch | 0.3 | 6.35 | 30 | Crafting |

| 3/4 inch | 0.8 | 19.1 | 16 | Construction |

Evaluating the Durability and Corrosion Resistance of Wire Mesh

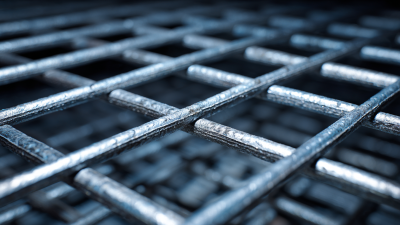

When selecting stainless steel wire mesh, durability and corrosion resistance are vital. Stainless steel is renowned for its strength, meaning it can endure heavy use. However, not all stainless steel is created equal. Different grades exhibit varying levels of resistance to rust and wear. Choosing the right grade for your environment is crucial. For instance, marine environments are harsher due to salt, requiring more specialized materials.

Corrosion resistance is often affected by the presence of impurities. Contaminants can lead to rust over time, compromising the mesh's integrity. Regular maintenance is essential to monitor any signs of degradation. Minor issues like surface rust can escalate if ignored. Pay attention to the manufacturing process too. Welded wire mesh may not perform as well in corrosive environments compared to woven types. The choice you make can impact longevity. Reflecting on your specific needs will help in selecting the right type.

Comparing Cost vs. Quality in Stainless Steel Wire Mesh Options

When considering stainless steel wire mesh, weighing cost against quality is crucial. Stainless steel mesh comes in various grades and specifications. Higher grades often come with a higher price tag. However, they offer better resistance to corrosion and prolong the lifespan of the material. For example, 304 and 316 grades serve different environments. Choosing the right grade impacts both performance and expense.

Quality may seem like an upfront cost but could lead to long-term savings. Cheaper options might need frequent replacements. Over time, this can lead to higher overall expenses. On the other hand, a high-quality option may require a more significant investment initially. Yet, the durability can save money down the road. It's essential to assess your unique needs and scenarios.

Additionally, details matter. Consider wire diameter and mesh size carefully. Smaller openings provide better filtration, but they may come at a higher cost. If you overlook these factors, you could end up with an option that doesn’t meet your requirements. Reflect on your specific usage to find the right balance. Costs may tempt you toward cheaper choices, but the consequences might lead to frustration.

Related Posts

-

What Are the Uses and Benefits of Stainless Steel Wire Mesh?

-

What is Perforated Metal? Exploring Uses, Benefits, and Design Options

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Understanding the Benefits of Using Steel Stair Treads in High Traffic Areas

-

Unlocking Strength: How Steel Mesh Reinforces Modern Construction Trends with 30% Increased Durability

-

What is Perforated Metal and Its Uses in Construction and Design