The Ultimate Guide to Choosing the Right Stainless Steel Mesh Screen for Your Home Projects

When embarking on home projects that require effective filtration, security, or aesthetic enhancement, selecting the right stainless steel mesh screen is crucial. According to a recent report by Market Research Future, the global stainless steel mesh market is projected to grow at a CAGR of 5.2% from 2021 to 2027, underscoring the increasing demand for these versatile materials across various applications. The unique properties of stainless steel mesh screens, including durability, corrosion resistance, and ease of maintenance, make them an ideal choice for homeowners. Furthermore, studies indicate that the proper selection of mesh design and wire diameter can significantly impact performance attributes such as airflow and structural integrity. This comprehensive guide aims to equip you with essential tips and insights, ensuring that you make an informed decision when choosing the perfect stainless steel mesh screen for your specific needs.

Understanding Different Types of Stainless Steel Mesh Screens Available

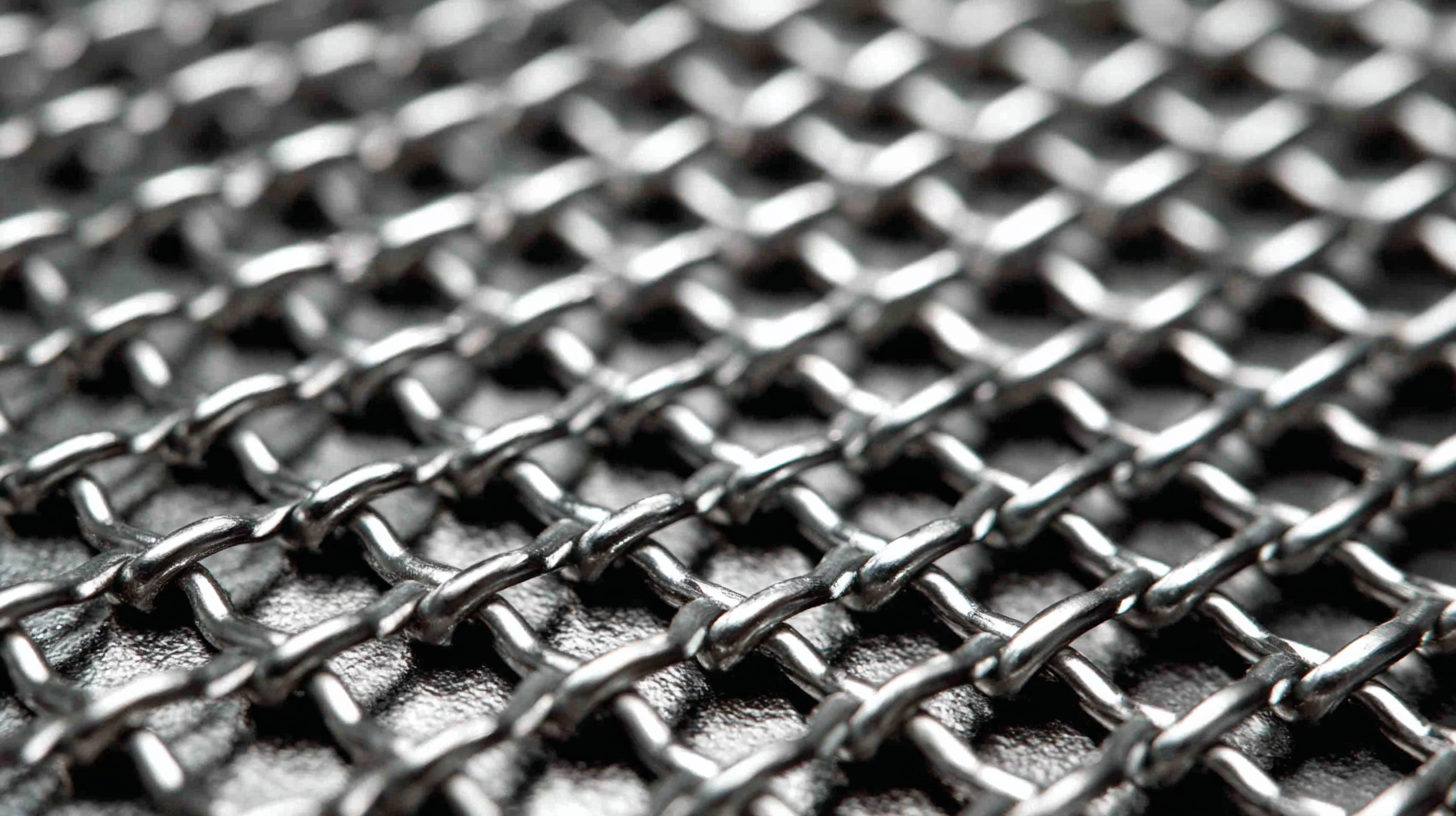

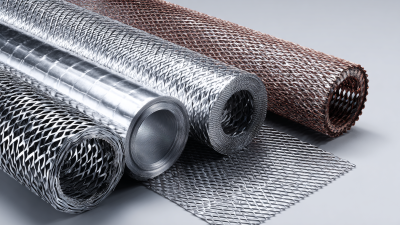

When selecting a stainless steel mesh screen for your home projects, it’s essential to understand the various types available. Stainless steel mesh screens come in different weaves, wire diameters, and hole sizes, each suited for specific applications. For instance, a plain weave offers a balanced combination of strength and flexibility, making it ideal for general use, while a twill weave provides enhanced tensile strength, perfect for applications requiring durability and resistance to deformation.

Tips: When choosing the right mesh, consider the environment in which it will be used. For outdoor projects exposed to the elements, opt for screens with higher corrosion resistance. Additionally, evaluate the mesh's hole size – smaller holes may be suitable for filtering fine debris, while larger holes facilitate airflow and light penetration.

Another common type is welded wire mesh, known for its stability and strength, often used in fencing or animal enclosures. If your project requires safety and security, consider using heavy-duty mesh that can withstand impact. Always make sure to gauge the mesh's specifications against your project needs to ensure optimal performance and longevity.

Key Factors to Consider When Choosing Stainless Steel Mesh for Your Needs

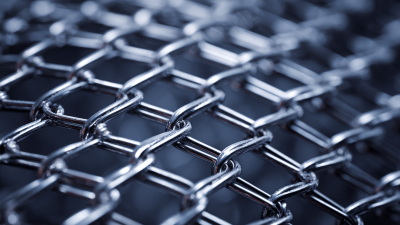

When selecting the appropriate stainless steel mesh screen for your home projects, several key factors must be considered to ensure you meet both functionality and longevity. First and foremost is the mesh size, which directly impacts the screen's filtration capabilities. According to recent industry studies, mesh sizes ranging from 10 to 80 are commonly used in residential applications, balancing air and liquid flow with effective particle retention. Choosing the right mesh size will depend on your specific needs, such as whether you’re using it for pest control, filtration, or architectural purposes.

Another critical aspect is the type of stainless steel alloy used in the mesh, as this determines its durability and resistance to corrosion. A report from the International Stainless Steel Forum highlights that 304 and 316 stainless steels are the most widely used grades, with 316 providing superior resistance to harsh environments due to its molybdenum content.

For outdoor applications or areas exposed to moisture and chemicals, opting for 316 stainless steel can significantly enhance the lifespan of your mesh screen, reducing long-term replacement costs and maintenance efforts.

Comparative Analysis of Stainless Steel Mesh Screen Grades and Their Applications

When selecting a stainless steel mesh screen for various home projects, understanding the different grades of stainless steel is crucial. Stainless steel mesh typically comes in grades such as 304, 316, and 430, each with distinct properties tailored for specific applications. Grade 304, known for its excellent corrosion resistance and durability, is suitable for general indoor use, including kitchen and household applications. Its affordability and versatility make it a popular choice for home improvement projects.

On the other hand, Grade 316 is a premium option that offers superior resistance to corrosion and pitting, particularly in harsh environments like coastal areas or chemical processing plants. This grade is ideal for outdoor applications, where weather resistance is vital. Meanwhile, Grade 430, while less resistant to corrosion than the first two, is often chosen for its magnetic properties and cost-effectiveness, making it suitable for decorative elements and applications where extreme conditions are not a concern. Understanding these distinctions helps homeowners select the appropriate stainless steel mesh screen that aligns with their project's specific needs and environmental factors.

The Ultimate Guide to Choosing the Right Stainless Steel Mesh Screen

This chart displays the corrosion resistance scores of various stainless steel mesh screen grades used in home projects. Grades like 316 offer superior resistance, making them ideal for marine environments, while Grade 430 is more suitable for less demanding applications.

Common Home Projects That Benefit from Stainless Steel Mesh Screens

When considering home improvement projects, integrating stainless steel mesh screens can significantly enhance both functionality and aesthetics. These screens serve various purposes, including providing protection, enhancing ventilation, and adding a touch of modern design to homes. Common projects that benefit from stainless steel mesh screens include window guards, porch enclosures, and outdoor kitchen installations, allowing homeowners to maximize their living spaces while ensuring safety and durability.

Tips: When choosing the right stainless steel mesh for your project, consider the weave type and the gauge of the material. A tighter weave can offer greater protection against pests, while a finer gauge can improve visibility and air flow.

Additionally, think about the intended use of the mesh screen. For instance, if you’re creating a cat window guard, ensure the screen is strong enough to withstand playful paws. Explore various design options to find a perfect match for your home's aesthetic, integrating both function and style seamlessly.

Maintenance Tips for Longevity of Your Stainless Steel Mesh Screens

When it comes to maintaining the longevity of stainless steel mesh screens, regular care and attention are essential. According to a report by the International Stainless Steel Forum, proper maintenance can extend the lifespan of stainless steel products by up to 50%. This means that simple cleaning practices can significantly enhance the durability of your screens, especially in environments exposed to moisture and harsh weather conditions. Regularly removing dust and debris using a soft brush or vacuum can prevent corrosion and other damage.

In addition to cleanliness, applying protective coatings can offer an additional layer of defense against environmental factors. The Stainless Steel Association recommends using a specialized stainless steel cleaner to remove stains and prevent rust build-up effectively. Studies have shown that stainless steel with a protective layer remains more resistant to oxidation, ensuring that your mesh screens not only perform optimally but also retain their aesthetic appeal. By incorporating these maintenance tips, homeowners can maximize the lifespan of their stainless steel mesh screens and enjoy their functional benefits for years to come.

Related Posts

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

Understanding the Benefits of Using Steel Stair Treads in High Traffic Areas

-

Choosing the Right Trench Drain Grate for Your Home Landscape Needs

-

Exploring the Versatility of Metal Mesh Screens: Innovative Applications Across Industries

-

Understanding the Importance of Stair Nosings for Safety and Aesthetics in Your Home