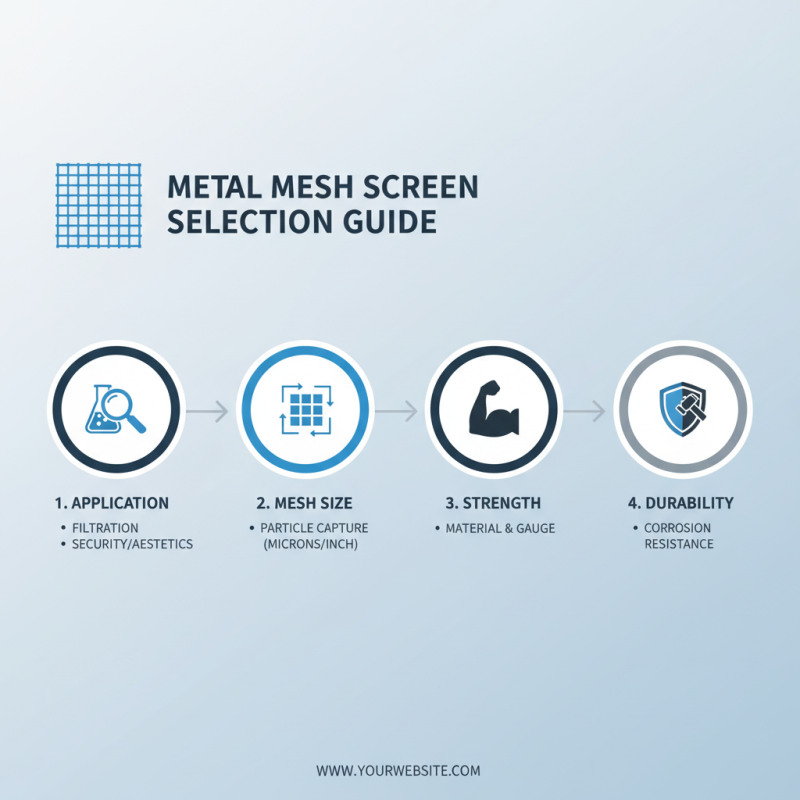

How to Choose the Right Metal Mesh Screen for Your Needs?

Choosing the right metal mesh screen can be challenging. It plays a crucial role in various applications, from construction to manufacturing. An industry expert, John Smith, emphasizes, "Selecting the right metal mesh screen is vital for efficiency and safety."

Metal mesh screens come in different materials, sizes, and designs. Each choice affects functionality. For example, stainless steel offers durability, while aluminum is lightweight and corrosion-resistant. Many people overlook the importance of wire diameter and mesh opening. These factors dramatically influence flow rates and filtration efficiency.

Sometimes, buyers make hasty decisions without proper research. This can lead to costly mistakes. Understanding your specific needs is essential. Each project requires careful consideration of the environment and usage. A wise choice can enhance performance and reduce future problems. Exploring options and seeking expert guidance often leads to better outcomes.

Understanding the Different Types of Metal Mesh Screens

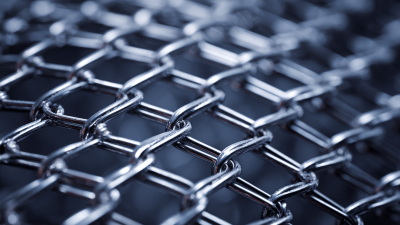

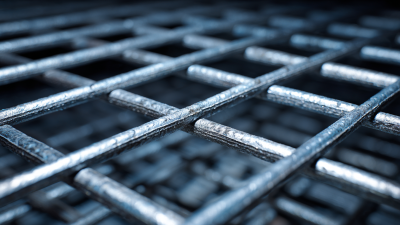

Choosing the right metal mesh screen requires understanding various types available on the market. Common options include woven wire mesh, expanded metal, and perforated metal sheets. Each type serves unique purposes. Woven wire mesh is great for filtration. Expanded metal offers strength with impressive airflow. Perforated metal combines durability and versatility.

When considering a metal mesh screen, think about the application. For high-traffic areas, you might need a sturdier option. If you're working with finer materials, a woven wire may be more beneficial. Remember to assess factors like the mesh size and hole pattern. These aspects impact both functionality and performance.

Tips: Always consider the environment. Will the screen face extreme temperatures or moisture? That affects material choice. Testing a few options can help find the best fit. Sometimes, it’s okay to explore different types. Trial and error can lead to surprising discoveries.

How to Choose the Right Metal Mesh Screen for Your Needs?

| Screen Type | Material | Mesh Size (Opening Size) | Wire Diameter | Applications |

|---|---|---|---|---|

| Woven Wire Mesh | Stainless Steel | 0.5 mm - 100 mm | 0.2 mm - 2 mm | Filtration, sieving, and separation |

| Perforated Metal Sheet | Mild Steel | 1 mm - 30 mm | 1 mm - 5 mm | Architectural elements, noise control |

| Expanded Metal Mesh | Aluminum | 5 mm - 50 mm | 0.5 mm - 3 mm | Grilles, safety guards, and decorative applications |

| Wire Cloth | Brass | 0.1 mm - 0.5 mm | 0.1 mm - 0.5 mm | Laboratory use, precision screening |

Assessing Your Specific Requirements for Metal Mesh Screens

Choosing the right metal mesh screen starts with understanding your specific needs. Think about the application. Are you using it for filtration, security, or aesthetics? Each purpose may require different characteristics. For example, a filtering screen needs a specific mesh size to capture desired particles. Security screens need strength and durability.

Consider the environment. Will the screen be used indoors or outdoors? Outdoor screens need to withstand weather conditions. This could mean looking for corrosion-resistant materials that can handle moisture. Reflect on the sizes and shapes that will fit your space. A standard size might not work for unique applications. Customization could be necessary. It’s important to weigh your options carefully.

Additionally, take time to evaluate any potential drawbacks. High-quality screens can be an investment. But lower-cost options may not always meet your expectations. Assess the balance between durability and cost. Do you need long-lasting materials or something more temporary? Each choice can significantly impact performance and functionality. The right decision may require some reflection and experimentation.

Evaluating the Material and Coating Options Available

Selecting the right metal mesh screen is crucial for various applications. The material you choose plays a significant role in defining durability and functionality. Stainless steel, aluminum, and brass are among the most common choices. Stainless steel is known for its corrosion resistance and strength, making it suitable for outdoor use. However, it might be more expensive compared to aluminum, which is lighter and more affordable but less robust.

Coating options also impact performance. Options like PVC coating offer additional protection against environmental elements. A recent industry report by MarketsandMarkets highlighted that coating can enhance the screen's lifespan by up to 30%. This is particularly important in industries like agriculture and construction, where durability is paramount.

Yet, options abound. Choosing the wrong mesh could lead to failures or increased maintenance costs. For example, uncoated aluminum might corrode in humid climates. Many users overlook the scale of mesh openings, which also affects functionality. Some might need finer mesh to filter debris effectively, while others may require larger openings for ventilation. Evaluating these factors is essential for meeting specific needs.

Determining Mesh Size and Open Area for Optimal Performance

Choosing the right metal mesh screen involves understanding mesh size and open area. A well-designed screen balances strength and airflow. The mesh size refers to the number of openings per linear inch. Smaller openings can filter finer particles. However, they may also restrict airflow.

Open area is crucial for performance. It's the percentage of total screen area that is free space. More open area results in better ventilation. But too much can compromise strength. Consider your application. For example, a dust filter needs a different mesh size than an air vent. It can be challenging to find a perfect match. Sometimes, compromises are necessary.

Evaluate the environment as well. Conditions can change over time. Screens exposed to moisture may corrode faster. Regular inspections can help detect such issues before they become problematic. Testing different sizes may be necessary to find the right fit. Trusting intuition may lead to unsatisfactory results. Prioritize careful research and trial to achieve optimal performance.

Considering Durability and Maintenance Factors in Selection

When selecting a metal mesh screen, durability is a key factor. Different materials exhibit varying resistance to corrosion, wear, and impact. For instance, stainless steel screens are known for their longevity. According to a recent industry report, stainless steel can last up to 30 years in outdoor settings. In contrast, aluminum may degrade faster, especially in harsh environments. This highlights the importance of considering the specific conditions where the screen will be used.

Maintenance is another critical consideration. Some metal mesh screens require frequent cleaning, while others can endure without much attention. For example, galvanized screens are often easy to maintain. However, their coating can chip, leading to rust if not monitored. A survey found that 40% of users reported unexpected maintenance issues with their screens. This statistic suggests that buyers should inquire about the best practices for keeping their chosen screen in good condition.

Deciding on the right mesh size is also essential. Finer meshes may trap more debris but can clog quickly, increasing the need for cleaning. Larger meshes may allow more airflow but can let in unwanted particles. A balanced choice is vital for efficiency. Users must weigh the benefits against the expectations of long-term durability and upkeep.

Related Posts

-

Exploring the Versatility of Metal Mesh Screens: Innovative Applications Across Industries

-

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights

-

Unlocking Strength: How Steel Mesh Reinforces Modern Construction Trends with 30% Increased Durability

-

Why Metal Mesh Screens Are Essential for Your Home and Business Needs

-

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

-

What is Perforated Metal and Its Uses in Construction and Design