2025 How to Choose the Right Aco Drain for Your Drainage Needs

Choosing the right drainage system can significantly influence the effectiveness and longevity of your outdoor and indoor environments. Among the various options available, the ACO drain stands out for its innovative design and practical applications. With a range of styles and materials, selecting the appropriate ACO drain involves understanding your specific drainage needs and the environment in which it will be installed.

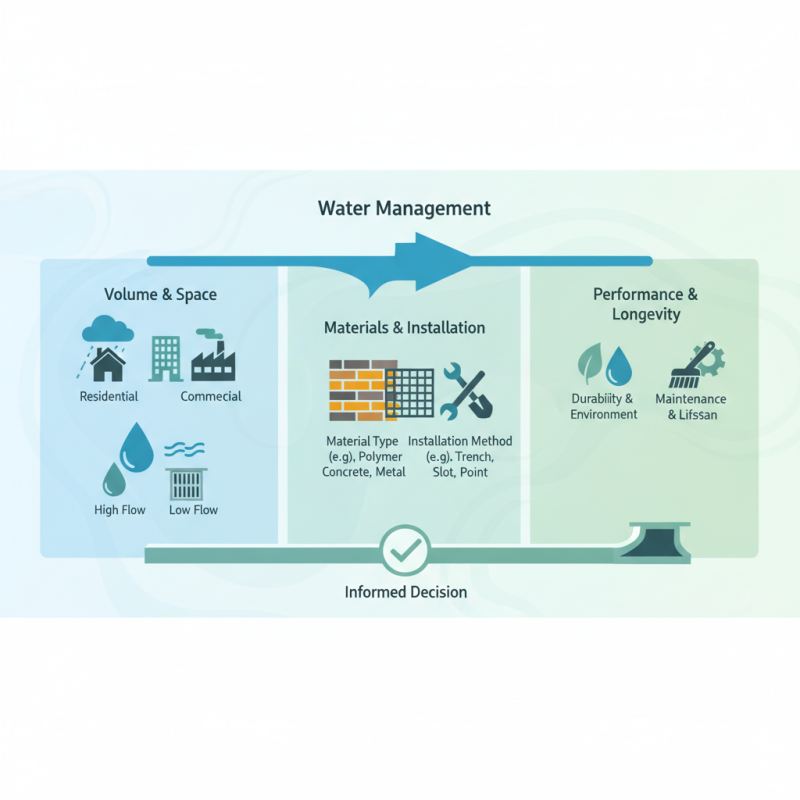

In this guide, we will explore crucial factors to consider when choosing the right ACO drain. From assessing the volume of water to be managed and the type of space—be it residential, commercial, or industrial—each aspect plays a vital role in determining the most suitable drain option. We will also discuss the importance of materials, installation methods, and maintenance to ensure optimal performance and longevity. By the end of this guide, you will be well-equipped to make an informed decision, ensuring your drainage systems are effective and durable for years to come.

Understanding Aco Drains: Types and Features

When selecting the right Aco drain for your drainage needs, it's essential to understand the different types and features available in the market. Aco drains are primarily categorized into three main types: channel drains, trench drains, and slot drains. Each type serves specific applications and environments, making it crucial to assess the drainage scenario. For instance, channel drains are often used in residential applications such as driveways and patios, while trench drains are preferable in commercial settings, particularly in areas that experience heavy water flow, like parking lots or industrial sites.

The features of Aco drains can significantly influence their performance. Key attributes to consider include the drainage capacity, material composition, and grating options. According to a report by the International Drainage and Civil Engineering Association, the efficiency of drainage systems can increase by up to 30% when the correct type and size of Aco drain are chosen. Moreover, the material of the drain, whether plastic, stainless steel, or polymer concrete, affects durability and resistance to corrosion or damage over time. Lastly, selecting the right grating not only enhances functionality but also impacts aesthetic appeal, particularly in venues where visual integration is important. Understanding these factors ensures optimal drainage performance tailored to specific needs.

Assessing Your Drainage Needs: Key Considerations

When selecting the appropriate Aco drain for your drainage needs, it's crucial to assess the specific requirements of your project. A comprehensive evaluation should consider factors such as the volume of water to be drained, the type of environment, and the anticipated load on the drainage system. According to the International Drainage Standards Association (IDSA), an average residential property requires a drainage system capable of handling approximately 1.5 inches of rain per hour. For commercial installations, this figure can increase significantly, necessitating a more robust solution.

In addition to water volume, the materials used for the Aco drain should match the surrounding environment. For instance, heavy-duty plastic drains may suffice for residential use, while cast iron or stainless steel drains are more suitable for industrial applications. A report from the American Society of Civil Engineers (ASCE) indicates that selecting the wrong drain can lead to maintenance issues and increased costs, with improper installations resulting in up to 30% higher expenses over the lifespan of the drainage system. Therefore, evaluating load-bearing capacity alongside the drainage volume is essential in ensuring longevity and efficiency in drainage solutions.

Evaluating Aco Drain Materials and Durability

When selecting an Aco drain, evaluating materials and their durability is paramount to ensure long-term performance and efficiency in drainage systems. The most common materials used for Aco drains include stainless steel, polymer concrete, and plastic. Stainless steel is highly valued for its resistance to corrosion, making it ideal for environments exposed to harsh chemicals or high moisture levels. Additionally, its strength and aesthetic appeal make it a great choice for locations requiring both functionality and visual compatibility.

Polymer concrete offers benefits such as lightweight construction and excellent load-bearing capacity, making it suitable for heavy-duty applications. Its durability is enhanced further by its resistance to various environmental factors, ensuring longevity even under rigorous conditions. On the other hand, plastic drains are lightweight and easy to install, providing a cost-effective solution for residential and low-impact commercial applications. However, when choosing plastic, it's important to consider factors like UV resistance and temperature tolerance, as these can affect overall performance over time.

Assessing the specific needs of your drainage system is essential in selecting the right material. Factors such as expected load, exposure to chemicals, and environmental conditions will dictate which material offers the best balance of durability and practicality. By prioritizing these aspects, you can ensure your Aco drain performs effectively, maximizing both efficiency and lifespan.

2025 How to Choose the Right Aco Drain for Your Drainage Needs - Evaluating Aco Drain Materials and Durability

| Material | Durability Rating | Weight (kg) | Temperature Resistance (°C) | Chemical Resistance |

|---|---|---|---|---|

| Polymer Concrete | High | 15 | -20 to 70 | Excellent |

| Stainless Steel | Very High | 20 | -40 to 500 | Good |

| Polyethylene | Medium | 10 | -30 to 60 | Fair |

| HDPE | Medium | 12 | -40 to 80 | Good |

| Cast Iron | Very High | 35 | -20 to 400 | Excellent |

Installation Requirements: What You Need to Know

When installing an Aco drain, understanding the installation requirements is crucial for ensuring optimal performance and longevity. First, it's important to assess the area where the drainage system will be placed. Proper grading is essential, allowing water to flow naturally towards the drain. Make sure the surface is leveled appropriately to prevent any pooling or blockage issues.

Tips:

- Measure the height of the drain before installation to ensure it aligns correctly with the surrounding surface.

- Use a spirit level to confirm the slope directs water toward the drain effectively, maintaining a gradient of at least 1% to 2%.

Next, consider the materials needed for installation. Ensure that you have high-quality components like geotextile fabrics for filtration and appropriate drainage pipes to connect to your Aco drain. Proper sealing and jointing will prevent leaks and enhance the system's efficiency.

Tips:

- Check local building codes and regulations regarding drainage systems to ensure compliance and avoid potential issues.

- Always allow for expansion joints in areas that may fluctuate in temperature to prevent cracking or damage.

By following these guidelines and tips, the installation of your Aco drain will meet both your drainage needs and the necessary standards for optimal function.

2025 Aco Drain Selection Insights

This chart illustrates the relative impact of various criteria when selecting Aco drains for drainage needs. The scores represent the importance of each criterion on a scale of 1 to 10, indicating Material Quality as the most critical factor.

Maintenance Tips for Ensuring Optimal Drain Performance

Maintaining optimal drain performance is crucial for ensuring the longevity and efficiency of your Aco drainage system. Regular inspection is the first step in effective maintenance. Checking for any signs of blockages or debris accumulation at the drainage entry points can prevent larger issues down the line. Clearing any visible debris will help maintain proper flow and minimize the risk of overflow or flooding, which can be detrimental to both the drainage system and surrounding areas.

In addition to routine inspections, it is essential to perform a thorough clean every few months. This can include flushing the drains with water to remove any sediment buildup and using specialized cleaning tools to clear stubborn blockages. Furthermore, seasonal maintenance checks should be a priority, especially before heavy rain periods, to ensure that your drainage system can handle increased water levels without issue.

By implementing these maintenance tips, you can significantly enhance the performance of your Aco drain and ensure it meets your drainage needs effectively.

Related Posts

-

Understanding the Benefits of Aco Drain Systems for Modern Drainage Solutions

-

Top 2025 Stainless Steel Mesh Screen Uses and Benefits You Need to Know

-

Enhancing Safety and Style: The Ultimate Guide to Choosing Steel Stair Treads for Your Home

-

What is Perforated Metal? Exploring Uses, Benefits, and Design Options

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

Enhancing Safety and Durability: The Essential Role of Aluminum Stair Treads in Public Infrastructure