How to Choose the Best Welded Wire for Your Projects and Applications

When it comes to selecting materials for construction and fencing projects, the choice of welded wire can significantly influence both the performance and longevity of the application. Welded wire is recognized for its exceptional strength, durability, and versatility, making it a preferred option across various industrial sectors. According to a market analysis by Grand View Research, the global welded wire market is projected to reach USD 12.87 billion by 2025, driven by increasing construction activities and a growing demand for effective security solutions.

As various applications utilize welded wire—from agriculture to residential fencing—it is essential to understand the specific requirements each project demands. For instance, the mesh size, gauge, and finish of welded wire can vary greatly, impacting its usability and resilience. A detailed report by Research and Markets indicates that factors like corrosion resistance and tensile strength are pivotal in determining the suitability of welded wire across environments. With the right selection, welded wire can provide a strong, safe, and aesthetically pleasing solution, tailored to the unique demands of each project.

In an industry moving towards sustainability and efficiency, understanding how to choose the best welded wire not only ensures optimal functioning but also contributes to overall project longevity and cost-effectiveness. Thus, gaining insight into specific applications and standards will facilitate informed decisions, ultimately enhancing project outcomes.

Understanding Welded Wire: Types and Materials

Welded wire is a versatile and durable fencing solution utilized across various applications, from agricultural setups to security enclosures. Understanding the types and materials of welded wire is crucial for selecting the best option for your specific project requirements. Primarily, welded wire is categorized into several types, including galvanized steel, stainless steel, and coated wire. Galvanized steel is the most common choice due to its corrosion resistance and cost-effectiveness, making it suitable for both indoor and outdoor use. According to a report by the Global Industrial Wire Market, galvanized wire accounted for over 40% of the market share in 2022, primarily driven by its demand in construction and agriculture.

When considering materials, the choice between stainless steel and plastic-coated wire can significantly influence the durability and performance of the welded wire. Stainless steel offers the highest level of corrosion resistance, making it ideal for harsh environments, while plastic-coated options provide additional protection and aesthetic appeal for those needing a less industrial look. In a recent industry analysis, it was noted that the demand for stainless steel welded wire has grown by approximately 25% over the past five years, highlighting a shift towards long-lasting materials in demanding applications. Selecting the right type and material of welded wire will ultimately enhance the project's longevity and effectiveness, ensuring it meets both functional and aesthetic needs.

How to Choose the Best Welded Wire for Your Projects and Applications

| Type of Welded Wire | Material | Wire Diameter (inches) | Mesh Size | Common Applications |

|---|---|---|---|---|

| Welded Wire Fencing | Galvanized Steel | 0.5 | 2"x4" | Animal enclosures, garden fencing |

| Welded Wire Panels | Stainless Steel | 0.25 | 1"x1" | Security fencing, outdoor structures |

| Welded Wire Mesh | Cold-Rolled Steel | 0.75 | 4"x4" | Concrete reinforcement, structural support |

| Welded Wire Fencing for Animals | Galvanized Coating | 0.5 | 1"x2" | Dog pens, livestock fencing |

| Decorative Welded Wire | Powder-coated Steel | 0.3 | 2"x2" | Garden trellises, decorative applications |

Key Factors to Consider When Choosing Welded Wire

When selecting the best welded wire for your projects and applications, there are several key factors to consider.

First and foremost, the gauge of the wire plays a crucial role in determining

the strength and durability of the finished product.

Thicker wires, indicated by a lower gauge number, provide greater strength and are suitable for heavy-duty applications

such as fencing livestock or creating robust enclosures. Conversely, thinner wires may suffice for lighter uses, such as

garden fencing or decorative purposes.

Another important aspect is the mesh size, which refers to the spacing

between the wires. Smaller mesh sizes offer enhanced security and are ideal for situations where smaller animals or even

debris need to be kept at bay. Additionally, you should consider the material

and finish of the welded wire.

Galvanized options resist rust and corrosion, making them more suitable for outdoor environments, while stainless steel

wires provide an even higher level of durability. By evaluating these factors—gauge, mesh size, and material—you can confidently

select the most appropriate welded wire to meet the specific needs of your projects.

Applications of Welded Wire in Various Industries

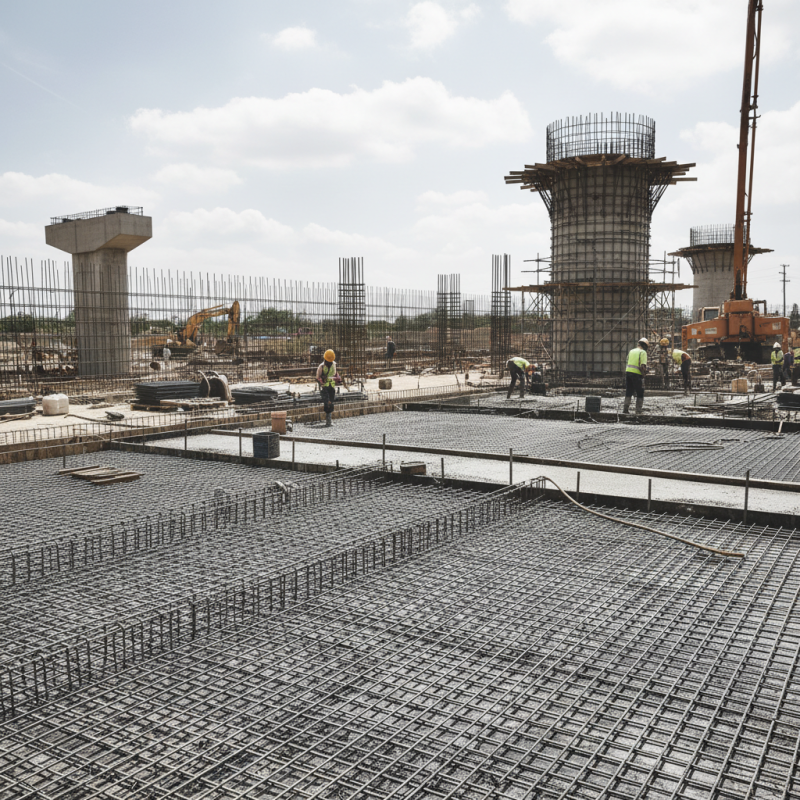

Welded wire has become a foundational material across varied industries due to its strength, durability, and versatility. Its applications stretch from construction and agriculture to manufacturing and security. According to a report by Freedonia Group, the demand for welded wire products in the construction sector is expected to grow by over 4% annually, driven by the rising need for robust fencing solutions and infrastructure projects. The rigidity and support provided by welded wire mesh make it an ideal choice for reinforcing concrete and creating safe enclosures.

In the agricultural industry, welded wire is extensively utilized for livestock containment and crop protection. The American Farm Bureau Federation highlights that strong, reliable fencing is vital for protecting livestock and preventing crop damage from wildlife. Additionally, welded wire is increasingly employed in horticulture for trellising plants, enabling efficient growth and improving yields. The versatility of welded wire in both indoor and outdoor applications showcases its importance in modern agricultural practices, as producers look for cost-effective solutions to enhance productivity. With its ability to endure harsh environments while maintaining structural integrity, welded wire remains a key material in meeting the diverse needs of various industries.

Comparing Strength and Durability of Different Welded Wire Options

When selecting welded wire for various projects, understanding the strength and durability of different options is crucial. Welded wire typically comes in various gauges and mesh sizes, which directly influence its load-bearing capacity and resistance to environmental factors. According to industry standards, a welded wire at a gauge of 10 can handle significantly higher tension than one at a gauge of 16, making it ideal for heavy-duty applications such as livestock enclosures or security fencing. A report from the American Wire Producers Association highlights that lower gauge wires offer better strength and longevity, especially in demanding conditions where resistance to corrosion and mechanical stress is vital.

Durability also varies by the type of coating applied to the wire. Galvanized welded wire, for example, is treated to resist rust and corrosion, increasing its lifespan significantly compared to uncoated options. The Wire Association International found that properly galvanized wire can last up to 30 years in harsh environments, while uncoated wire shows signs of deterioration within just a few years. Furthermore, wire mesh that includes a polymer coating offers enhanced UV resistance, making it suitable for outdoor projects. Evaluating these factors alongside project requirements ensures you opt for the most appropriate welded wire, maximizing both performance and longevity.

Cost-Effectiveness: Evaluating Your Welded Wire Budget

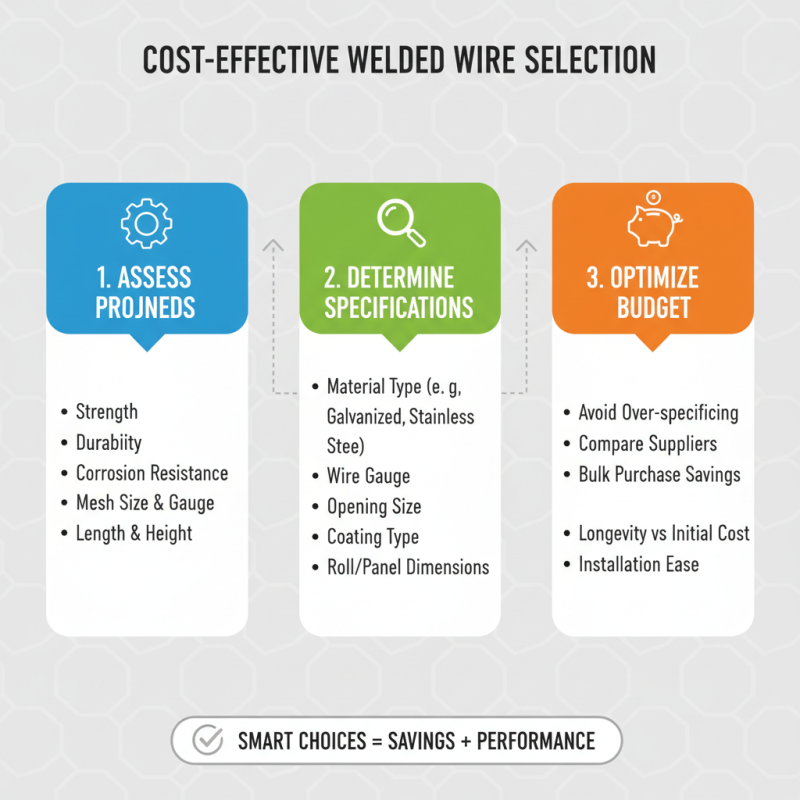

When selecting welded wire for your projects, understanding the cost-effectiveness of your choices is crucial. Budgets can vary widely based on project size, application, and material quality. Begin by assessing the specific requirements of your project, such as the strength, durability, and corrosion resistance of the wire. This will help you determine the necessary specifications and avoid overspending on unnecessary features.

Once you have a clear understanding of your needs, compare prices from different suppliers while considering the long-term value each option offers. Cheaper materials may save money upfront but can lead to higher maintenance costs or replacements in the future. Therefore, a balance between initial cost and overall lifetime value is essential. Additionally, factor in any shipping costs or potential discounts for larger orders, as these aspects can significantly impact your budget. By carefully evaluating these factors, you can make an informed decision that aligns with your financial constraints while ensuring the successful completion of your project.

Related Posts

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

-

2025 How to Choose the Right Drain Grate for Your Landscape Design

-

Choosing the Right Trench Drain Grate for Your Home Landscape Needs

-

Understanding the Importance of Stair Nosings for Safety and Aesthetics in Your Home