2025 How to Choose the Best Welded Wire for Your Project

In the realm of construction and manufacturing, choosing the right materials is paramount for ensuring structural integrity and longevity of projects. Welded wire, with its impressive strength and versatility, has emerged as a favored choice across various applications, from fencing to reinforcement in concrete structures. According to a recent industry report published by the Wire Association International, the demand for welded wire products is projected to increase by 5% annually over the next five years, underscoring its growing relevance in the construction sector.

Expert insights also highlight the critical considerations in selecting the appropriate welded wire for specific projects. Leading materials engineer Dr. John Smith states, "Selecting the right type of welded wire not only enhances the strength of the structure but also impacts the overall cost-effectiveness and durability." Dr. Smith emphasizes the importance of understanding the different specifications and applications of welded wire, as improper selection can lead to inefficiencies and increased costs in the long run.

As we delve into the factors influencing the choice of welded wire, it is essential to examine various elements such as wire gauge, spacing, and material composition. Being equipped with this knowledge will empower project managers and contractors to make informed decisions that align with their project's requirements, ultimately leading to successful outcomes.

Understanding the Different Types of Welded Wire Available

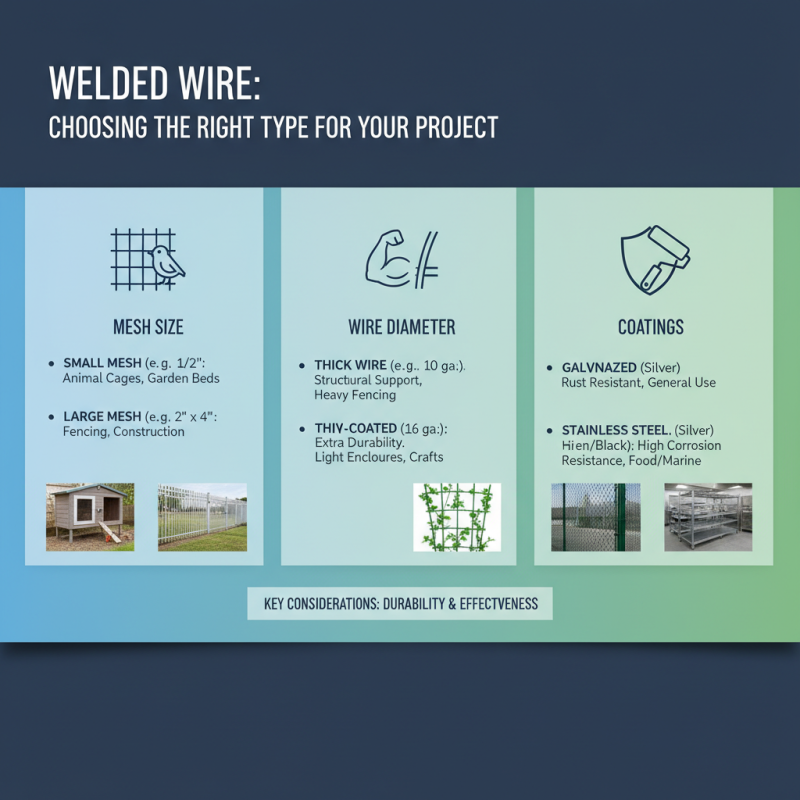

When selecting the best welded wire for your project, it's essential to understand the various types available, each suited for specific applications. Welded wire comes in different mesh sizes, wire diameters, and coatings, which can significantly influence its durability and effectiveness. For instance, a smaller mesh size is ideal for applications requiring containment of small animals or plants, while larger mesh sizes are better suited for fencing or construction purposes. The choice of wire diameter also plays a critical role in strength; thicker wires provide enhanced support for heavy applications, while thinner wires may suffice for lighter loads.

Moreover, the type of coating on welded wire can affect both its longevity and resistance to corrosion. Galvanized wire tends to resist rust and corrosion better than black wire, making it a popular choice for outdoor projects. Additionally, you’ll find options such as PVC-coated wire which not only offers protection from the elements but also adds an aesthetic appeal, blending seamlessly into landscape designs. By understanding these different types of welded wire and their characteristics, you can make a more informed decision that aligns with the specific needs of your project.

Key Factors to Consider When Selecting Welded Wire

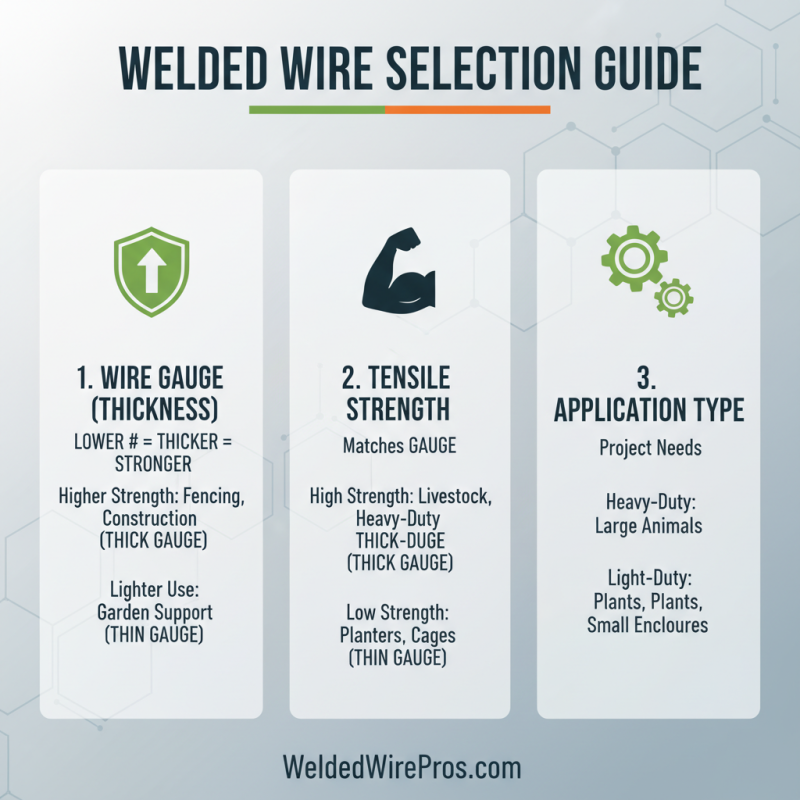

When selecting welded wire for your project, there are several key factors to consider to ensure that you choose the best material for your needs. First, evaluate the gauge of the wire, which refers to the thickness. A lower gauge number indicates thicker wire, providing greater strength and durability. If your application demands high tensile strength, such as fencing for livestock or heavy-duty construction, opt for a thicker gauge. Conversely, for lighter applications like garden supports, a thinner gauge may suffice.

Additionally, consider the spacing of the welds and the mesh openings. The size of the openings impacts the wire's suitability for specific tasks. For example, smaller openings are ideal for keeping smaller animals contained, while larger openings can be effective for general reinforcement purposes. Always assess the environmental conditions where the wire will be installed, as weather exposure can influence material selection.

**Tips:** Always look for welded wire with a protective coating, such as galvanized or vinyl coating, to enhance its resistance to rust and corrosion, which is vital for outdoor use. Also, be sure to test the weight that will be applied to the wire in its intended use; overloading can compromise its integrity. Lastly, reviewing customer feedback or consulting with experts can provide insight into the performance of different welded wire types.

Evaluating the Strength and Durability of Welded Wire Options

When selecting the best welded wire for your project, evaluating the strength and durability of different options is crucial. According to a report by the American Society for Testing and Materials (ASTM), wire mesh that meets standard specification A185 is tested for minimum yield strength of 50,000 psi, which is an essential factor in ensuring that the welded wire can withstand significant loads and stressors in various applications. Whether you're using the wire for fencing, reinforcement, or industrial applications, understanding these strength metrics helps ensure that your selection aligns with the demands of your project.

Durability is another key consideration when choosing welded wire. Research indicates that galvanized welded wire can exhibit double the lifespan compared to non-galvanized options, particularly in environments exposed to moisture and corrosive elements. The International Wire & Machinery Association (IWMA) emphasizes that materials treated for corrosion resistance not only enhance longevity but also reduce maintenance costs over time. By prioritizing both strength and durability, project managers can select welded wire that not only meets immediate needs but also stands the test of time, ultimately contributing to the project's success and sustainability.

2025 How to Choose the Best Welded Wire for Your Project - Evaluating the Strength and Durability of Welded Wire Options

| Wire Type | Wire Diameter (Gauge) | Mesh Size (Inches) | Coating Type | Strength Rating (lbs) | Durability (Rating from 1 to 5) |

|---|---|---|---|---|---|

| Galvanized Steel | 14 | 2 x 4 | Zinc Coated | 1200 | 5 |

| Stainless Steel | 16 | 1 x 2 | Uncoated | 1500 | 5 |

| PVC Coated Steel | 12 | 2 x 4 | PVC Coated | 1000 | 4 |

| Electrowelded Wire | 18 | 1 x 1 | Galvanized | 800 | 3 |

Determining the Suitable Wire Gauge for Your Project Needs

When selecting welded wire for your project, one of the most crucial factors to consider is the wire gauge. Wire gauge refers to the thickness of the wire, which directly impacts its strength, flexibility, and suitability for various applications. According to data from the Wire Association International, the gauge size of welded wire meshes typically ranges from 8 to 12 gauge. A higher gauge number indicates a thinner wire, while a lower gauge corresponds to a thicker wire. Understanding the requirements of your project, such as load-bearing capacity and environmental exposure, will guide you in selecting the appropriate wire gauge.

For instance, a project requiring significant structural support, like fencing for livestock or construction barriers, will often benefit from a lower gauge, such as 8 or 10 gauge wire, which can bear higher loads due to its added strength. Conversely, lighter applications such as garden fencing or decorative projects may only require 12 or 14 gauge wire, offering adequate support while remaining cost-effective. Research published in the American Society of Civil Engineers highlights the importance of selecting the right gauge; projects that fail to account for appropriate wire strength risk structural integrity and increased maintenance costs. Thus, a careful evaluation of wire gauge is essential for achieving optimal results in your welded wire projects.

Cost Analysis: Budgeting for Your Welded Wire Project

When budgeting for your welded wire project, it's essential to consider various factors that can impact overall costs. The type and gauge of wire you choose play a significant role in your budget. Heavier gauges may be more durable but will also increase your expenses. Additionally, the length and height of the wire panels will directly affect the amount you need to purchase. Carefully measuring your project requirements can help prevent overbuying and ensure that you stay within budget.

Tips for achieving cost efficiency include shopping around for suppliers and comparing prices. It’s also beneficial to ask for bulk discounts if you plan to purchase a large quantity of welded wire. Another useful strategy is to consider alternative materials that may offer similar benefits at a lower price. Always factor in potential additional costs such as shipping, installation, and maintenance to get a comprehensive view of your financial commitment.

Finally, it’s wise to prepare for unexpected expenses. Having a contingency budget, typically around 10-15% of your total project cost, can provide a safety net and allow for adjustments if prices fluctuate or additional materials are needed. By taking these budgeting tips into account, you can better navigate the financial aspects of your welded wire project and make informed decisions.

2025 Welded Wire Cost Analysis for Projects

This chart represents the estimated costs of different types of welded wire for various project sizes. The data considers factors such as wire gauge, material, and quantity required.

Related Posts

-

How to Choose the Best Welded Wire for Your Projects and Applications

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Mesh

-

How to Choose the Best FRP Grating for Your Project Needs

-

What is Perforated Metal? Exploring Uses, Benefits, and Design Options