How to Choose the Best FRP Grating for Your Project Needs

When embarking on a project that requires durable and lightweight flooring solutions, choosing the right FRP grating is essential. Fiber Reinforced Plastic (FRP) grating offers a range of benefits, including corrosion resistance, strength, and low maintenance, making it an ideal choice for various applications from industrial to commercial settings. However, with a plethora of options available, making an informed decision can seem daunting.

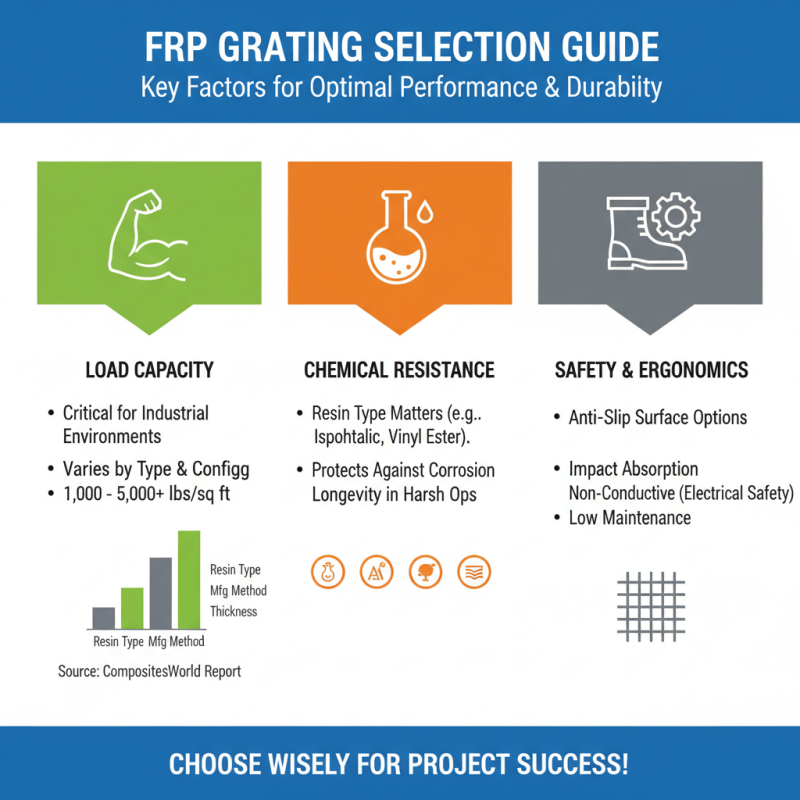

In this guide, we will explore key factors to consider when selecting the best FRP grating for your specific project needs. Understanding the unique characteristics of different grating types, such as load capacity, environmental compatibility, and aesthetic options, will help ensure that your choice aligns with performance requirements and budget constraints. Whether you need grating for walkways, drainage covers, or platforms, knowing what to prioritize will lead to an effective and satisfying implementation of FRP grating in your project.

Understanding the Different Types of FRP Grating Materials Available

When selecting the best FRP (Fiber Reinforced Polymer) grating for your project, it is essential to understand the various types of materials available. FRP grating is typically made from different resin types, including polyester, vinyl ester, and epoxy. Polyester is the most common choice due to its cost-effectiveness and sufficient chemical resistance for many applications. However, for environments where exposure to aggressive chemicals is a concern, vinyl ester offers enhanced durability and performance. Epoxy grating, while generally more expensive, provides superior mechanical strength and is ideal for high-load applications, making it a reliable option for demanding industrial environments.

Additionally, the type of fiberglass reinforcement used in the grating can significantly affect its performance. Standard fiberglass may be adequate for lighter applications, but for increased load-bearing capacity, the incorporation of higher-grade fiberglass can enhance structural integrity. Furthermore, environmental factors such as corrosion resistance, fire rating, and UV stability should also be considered. By carefully analyzing your project's specific requirements in relation to the different types of FRP grating materials available, you can make an informed decision that ensures long-lasting performance and safety.

Different Types of FRP Grating Materials

Key Factors to Consider When Selecting FRP Grating for Your Project

When selecting the best Fiber Reinforced Polymer (FRP) grating for your project, several key factors should be considered to ensure optimal performance and durability. One critical aspect is load capacity, which varies significantly based on the type and configuration of the grating. According to a report by the CompositesWorld, the load-bearing capacity of FRP gratings can range from 1,000 to over 5,000 pounds per square foot, depending on the resin type, manufacturing method, and thickness. This information is vital for projects in industrial environments where heavy machinery or foot traffic may be present.

Another significant factor to consider is the environmental resistance of the FRP grating. The American Composites Manufacturers Association (ACMA) indicates that FRP materials are resistant to corrosion, UV degradation, and thermal fluctuations, making them suitable for various applications, including marine and chemical facilities. It is essential to review the specific environmental conditions your project will encounter, as certain resins may provide better chemical resistance or UV stabilization over time. Assessing these aspects will help ensure that the selected FRP grating meets the longevity and safety requirements of your project while also providing a cost-effective solution in the long run.

Assessing Load Capacity: Standards and Specifications for FRP Grating

When selecting FRP (Fiberglass Reinforced Plastic) grating for a project, understanding the load capacity is paramount. The load capacity of FRP grating is determined by various standards and specifications that ensure the material can withstand the intended loads for a specific application. These standards, often established by organizations like ASTM or ANSI, outline the testing methods and performance criteria required to verify the strength and durability of the grating. It's important to consult these specifications to confirm that the grating you choose meets the demands of your specific industry requirements, whether it be for industrial flooring, walkways, or platforms.

In addition to adhering to established standards, evaluating the load capacity involves considering factors such as the type of load (static or dynamic), the distribution of weight, and environmental conditions that may affect performance. FRP grating products often come with load tables that indicate the maximum safe load for various grating spans. By carefully assessing these criteria, engineers and project managers can make informed decisions, ensuring that the chosen FRP grating not only supports operational needs but also maintains safety and compliance with regulatory standards. Proper selection based on these assessments is essential to optimizing the longevity and effectiveness of FRP grating solutions in diverse applications.

Evaluating Chemical Resistance and Other Environmental Conditions

When selecting FRP (Fiberglass Reinforced Plastic) grating for a specific project, evaluating chemical resistance is crucial, particularly in environments exposed to harsh substances. According to a report by the American Society for Testing and Materials (ASTM), FRP materials can offer varying degrees of resistance based on the resin type and the presence of fillers or additives. For instance, vinyl ester resins are often preferred for their superior resistance to corrosive chemicals such as concentrated acids and alkalis, making them ideal for industrial applications.

Additionally, environmental conditions must be considered alongside chemical resistance. A study presented at the Composite Materials Conference revealed that UV exposure significantly affects FRP’s structural integrity over time, with some formulations showing a reduction in tensile strength of over 20% after prolonged exposure. Thus, when selecting FRP grating, it's vital to assess not only the chemical environment, such as the presence of corrosive agents, but also the potential impact of UV radiation and temperature fluctuations. Ensuring that the chosen grating can withstand these conditions will enhance its longevity and effectiveness in the intended application.

Cost Analysis: Comparing FRP Grating with Traditional Materials

When evaluating the cost of FRP (Fiberglass Reinforced Plastic) grating against traditional materials such as steel and wood, it’s essential to consider not only the upfront material costs but also long-term factors such as maintenance, durability, and life cycle. A study published by the Composites Market Research indicates that FRP grating systems can be up to 40% lighter than comparable steel options, which can drastically reduce transportation and installation costs. Additionally, the corrosion resistance of FRP means it requires less maintenance over its lifespan, leading to reduced labor costs and extended service life.

In terms of initial investment, while FRP grating may have a higher purchase price than some traditional materials, the total cost of ownership can be significantly lower. A report by the American Composites Manufacturers Association suggests that over a projected 20-year lifespan, the savings associated with reduced maintenance and replacement needs can outweigh the initial cost difference by a factor of 3:1 in favor of FRP grating. This makes it a compelling option for projects where durability and reduced downtime are critical, particularly in harsh environmental conditions.

How to Choose the Best FRP Grating for Your Project Needs - Cost Analysis: Comparing FRP Grating with Traditional Materials

| Material Type | Cost per Square Foot | Weight (lbs/sq ft) | Corrosion Resistance | Lifespan (Years) | Maintenance Requirements |

|---|---|---|---|---|---|

| FRP Grating | $30 - $50 | 1.5 | Excellent | 25 - 30 | Low |

| Steel Grating | $20 - $35 | 2.5 | Moderate | 10 - 20 | Medium |

| Aluminum Grating | $25 - $45 | 2.0 | Good | 15 - 25 | Low |

| Wooden Grating | $15 - $30 | 3.0 | Poor | 5 - 10 | High |

Related Posts

-

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

-

Why Metal Mesh Screens Are Essential for Your Home and Business Needs

-

Exploring the Versatility of Metal Mesh Screens: Innovative Applications Across Industries

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

How to Choose the Best Welded Wire for Your Projects and Applications

-

The Ultimate Guide to Choosing the Right Stainless Steel Mesh Screen for Your Home Projects