Top 10 Benefits of Using Welded Wire for Your Construction Projects

In the realm of construction, selecting the right materials can significantly impact the durability, safety, and overall success of your project. One of the most reliable and versatile options available today is welded wire. This innovative material, consisting of a grid of wires that have been electrically fused at their intersections, offers a myriad of advantages that can enhance the efficiency and structural integrity of your construction endeavors. As industries strive for cost-effective and robust solutions, welded wire emerges as a prominent choice for builders and engineers alike.

Welded wire not only provides exceptional strength and durability but also streamlines the construction process, making it a preferred alternative to traditional reinforcement methods. Its uniform design minimizes the likelihood of weak points, ensuring a long-lasting foundation for various projects, from residential buildings to infrastructure developments. Moreover, welded wire's lightweight nature facilitates easier handling and installation, translating to significant time and labor savings on-site. As we delve into the top ten benefits of using welded wire for your construction projects, it becomes evident that this material is not merely a trend but a fundamental component in modern engineering practices.

Advantages of Welded Wire in Structural Integrity and Safety

Welded wire is an essential component in modern construction projects due to its significant contributions to structural integrity and safety. One of the primary advantages of using welded wire is its ability to distribute loads evenly throughout a structure. Unlike some traditional reinforcement methods, welded wire mesh forms a continuous network that enhances the tensile strength of concrete. This uniform load distribution minimizes the risk of cracking and failure, which is crucial for maintaining the durability of various constructions, including pavements, walls, and foundations.

Additionally, the inherent properties of welded wire contribute to overall safety in building projects. Its robust design allows for higher resistance to both static and dynamic loads, which is particularly important in areas prone to seismic activity or heavy traffic. The rigidity and stability provided by welded wire reduce the likelihood of deformation over time, ensuring that structures remain safe and sound throughout their lifespan. Moreover, the ease of installation of welded wire also plays a significant role in promoting safety during construction, as it simplifies the reinforcement process and reduces the chances of human error.

Top 10 Benefits of Using Welded Wire for Your Construction Projects - Advantages of Welded Wire in Structural Integrity and Safety

| Benefit | Description | Impact on Construction |

|---|---|---|

| Durability | Welded wire exhibits high resistance to corrosion and wear. | Enhances longevity of structures. |

| Strength | Provides structural reinforcement with high tensile strength. | Improves load-bearing capacity. |

| Cost-Effective | Lower material costs compared to alternatives. | Reduces overall project expenses. |

| Versatility | Applicable in various construction applications. | Adapts to diverse structural needs. |

| Ease of Installation | Quick to install, reducing labor time. | Speeds up project timelines. |

| Safety | Provides enhanced stability, reducing risk of failure. | Increases worker safety on-site. |

| Aesthetic Appeal | Can be designed for visual integration. | Enhances visual elements of structures. |

| Eco-Friendliness | Often made from recycled materials. | Supports sustainable construction practices. |

| Reduced Maintenance | Requires less upkeep over time. | Lowers long-term maintenance costs. |

| Fire Resistance | Non-combustible material offers fire safety. | Improves structural safety in fire events. |

Cost-Effectiveness of Welded Wire in Construction Projects

Welded wire has emerged as a cost-effective solution for various construction projects, providing both efficiency and reliability. A recent industry report indicates that using welded wire can reduce material costs by up to 20% compared to traditional reinforcement methods. This significant savings stems from the speed and ease of installation, allowing construction teams to allocate resources more effectively and speed up project timelines. Coupled with its strength and versatility, welded wire serves as an optimal choice for concrete reinforcement and other applications, resulting in lower overall costs for contractors.

When considering welded wire for your construction endeavors, it's essential to evaluate the long-term benefits beyond initial expenditures. For instance, welded wire mesh has been shown to enhance the structural integrity of constructions and reduce the probability of future repairs. Reports have found that structures utilizing welded wire can effectively decrease maintenance costs by an estimated 15%, significantly impacting long-term project budgets.

Tips for maximizing cost-effectiveness with welded wire include ensuring adequate planning and sizing of mesh for specific projects to prevent wastage. Additionally, collaborating with experienced professionals who understand the latest industry practices can lead to more informed decisions, ultimately maximizing the value derived from your investment in welded wire solutions.

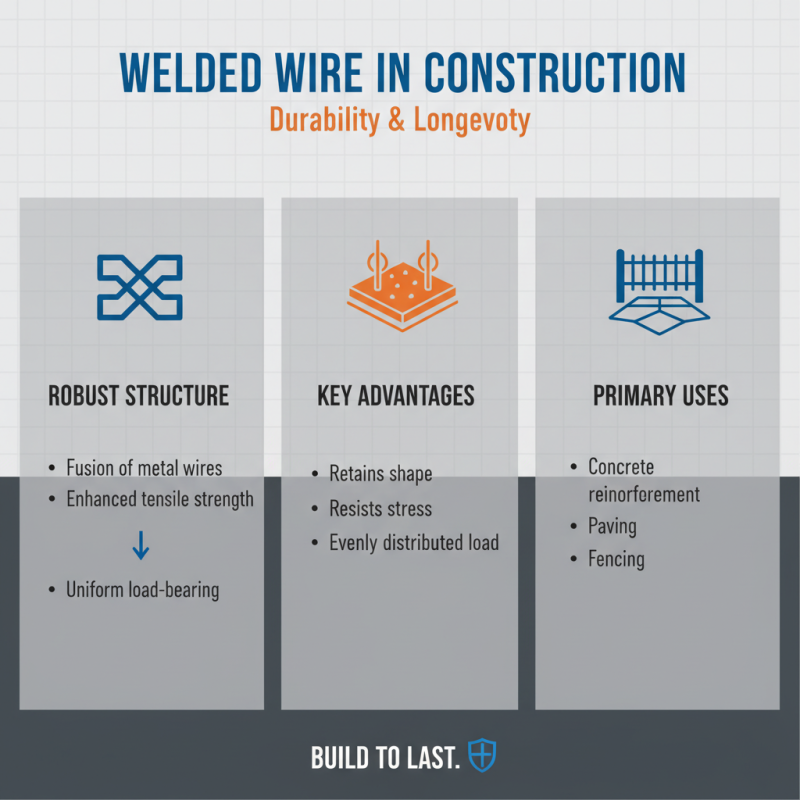

Durability and Longevity of Welded Wire Materials

Welded wire materials are increasingly favored in construction projects due to their impressive durability and longevity. One of the primary advantages of welded wire is its robust structure, which is created through the fusion of metal wires at intersections. This method not only enhances the tensile strength of the material but also creates a uniform and evenly distributed load-bearing capacity. As a result, welded wire retains its shape and integrity under various stress conditions, making it an ideal choice for reinforcing concrete, paving, and fencing applications.

Moreover, the longevity of welded wire materials is further augmented by their resistance to environmental factors such as rust and corrosion. When properly coated or treated, welded wire can withstand exposure to moisture, chemicals, and temperature fluctuations, thereby prolonging its lifespan. This inherent resistance translates to lower maintenance costs and a reduced need for replacement, which is particularly beneficial for large-scale construction projects where sustainability and cost-efficiency are paramount. By opting for welded wire, builders can ensure that their structures endure the test of time while maintaining safety and aesthetic appeal.

Versatility of Welded Wire in Various Construction Applications

Welded wire has emerged as a versatile solution in the realm of construction, catering to a wide array of applications ranging from structural reinforcement to fencing. Its design, featuring a grid of intersecting wires welded at their junctions, provides exceptional strength and stability. According to a report by the Global Welded Wire Mesh Market, the expansion in the construction industry is projected to elevate the demand for welded wire products significantly, anticipating a growth rate of over 7% annually through 2028. This statistic illustrates the growing recognition of welded wire's utility across diverse construction scenarios.

In framed structures, welded wire is often employed for slab reinforcement, enhancing durability and reducing cracking. The American Concrete Institute emphasizes that using welded wire mesh in concrete slabs can increase load-bearing capacity considerably, contributing to safer and more efficient constructions. Furthermore, in landscaping and agricultural applications, its adaptability for barriers and supports showcases its multifaceted nature, addressing the needs of both urban and rural settings. The material's capability to endure harsh environmental conditions also makes it an ideal choice for long-lasting installations.

Moreover, welded wire's economical aspect cannot be overlooked. The efficient manufacturing process reduces material waste, allowing for cost-effective construction solutions without compromising quality. A construction materials report highlights that projects utilizing welded wire can see reduced labor costs due to the ease of installation, ultimately making welded wire an invaluable resource for construction professionals looking to optimize both performance and budget.

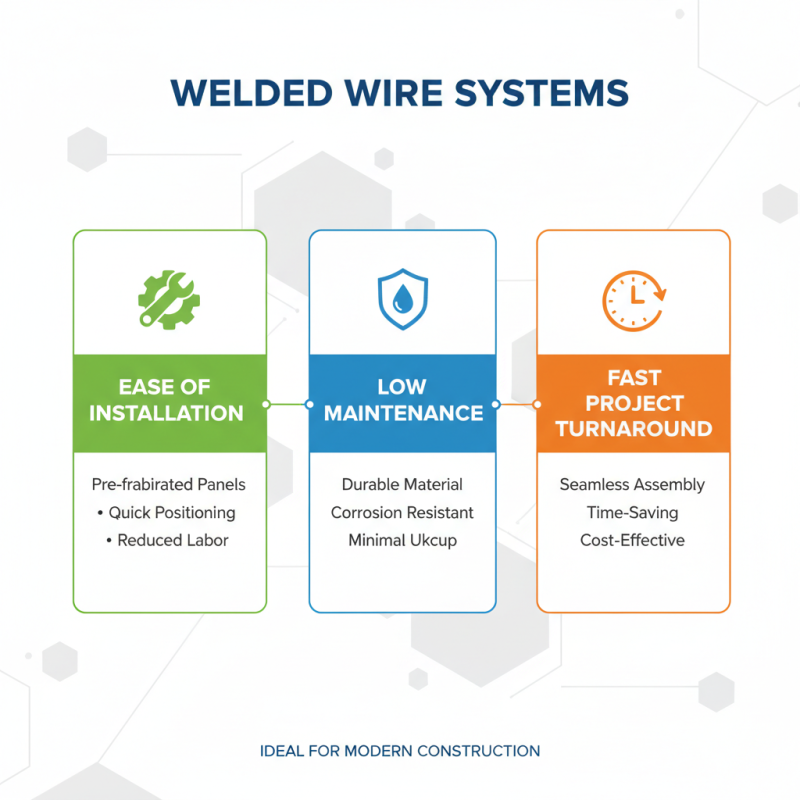

Ease of Installation and Maintenance of Welded Wire Systems

Welded wire systems have gained popularity in construction projects due to their ease of installation and low maintenance requirements. One of the primary advantages of using welded wire is the straightforward assembly process. With pre-fabricated panels, contractors can quickly position the wire sections and secure them in place, significantly reducing labor time and costs. This seamless installation process allows for quick project turnaround, making it an ideal choice for time-sensitive builds.

Additionally, maintenance concerns are minimal with welded wire structures. The durable nature of the welded wire ensures long-lasting performance with little to no upkeep needed. Unlike traditional fencing or mesh systems that may require frequent inspections or repairs due to rust or wear, welded wire systems withstand various environmental conditions without compromising integrity. This reliability not only keeps projects within budget but also minimizes disruptions, allowing for more efficient overall project management. With these benefits, welded wire systems are a practical solution for modern construction challenges.

Related Posts

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

How to Choose the Best Welded Wire for Your Projects and Applications

-

2025 How to Choose the Best Welded Wire for Your Project

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

2025 Top Uses and Benefits of Expanded Metal Sheet in Construction and Design

-

Why Metal Mesh Screens Are Essential for Your Home and Business Needs