Understanding the Benefits of Using Steel Stair Treads in High Traffic Areas

In today's bustling environments, the safety and durability of flooring solutions are paramount, particularly in high traffic areas where the risk of slips and falls is significantly elevated. One highly effective solution to address these concerns is the incorporation of steel stair treads. These specialized treads not only enhance safety through improved traction but also offer remarkable durability under constant use. The robust nature of steel ensures that stair treads can withstand the wear and tear of heavy foot traffic, making them an ideal choice for various applications, from commercial buildings to industrial settings. Moreover, steel stair treads can be designed with features such as anti-slip surfaces, contributing further to the prevention of accidents. This article delves into the numerous benefits of using steel stair treads, highlighting their importance in maintaining safety, reducing maintenance costs, and ensuring longevity in high traffic areas.

Identifying High Traffic Areas Suitable for Steel Stair Treads

When considering environments prone to heavy foot traffic, identifying suitable locations for steel stair treads is essential. High traffic areas typically include commercial buildings, public transport hubs, and educational institutions, where the sheer volume of movement can lead to wear and tear on stairs. Steel stair treads offer a durable solution, enhancing safety while extending the lifespan of stairway surfaces.

Tips: Regularly inspect high-traffic areas for signs of wear, ensuring you replace or repair treads as needed. Additionally, opt for steel treads with anti-slip surfaces to further enhance safety in crowded settings.

Another ideal location for steel stair treads is industrial sites where heavy machinery and equipment are often transported. The strength and resilience of steel provide the necessary support to withstand the daily rigors of such environments. Implementing steel treads not only provides safety and durability but also contributes to the overall aesthetic of the space, making it a smart investment for any facility facing substantial foot traffic.

Tips: Consider the specific requirements of your facility, including load-bearing capabilities and environmental conditions, when selecting steel treads. This will ensure optimal performance and longevity in high-traffic areas.

Evaluating the Durability and Longevity of Steel Stair Treads

Steel stair treads are increasingly recognized for their durability and longevity, making them an excellent choice for high traffic areas. Unlike traditional materials such as wood or plastic, steel is inherently resistant to wear and tear, ensuring that stair treads maintain their structural integrity even under continuous use. The robust nature of steel means that it can withstand heavy loads and impacts, significantly reducing the frequency of replacements and repairs. This durability translates to lower maintenance costs over time, making steel treads a cost-effective solution for facilities that experience heavy foot traffic.

Steel stair treads are increasingly recognized for their durability and longevity, making them an excellent choice for high traffic areas. Unlike traditional materials such as wood or plastic, steel is inherently resistant to wear and tear, ensuring that stair treads maintain their structural integrity even under continuous use. The robust nature of steel means that it can withstand heavy loads and impacts, significantly reducing the frequency of replacements and repairs. This durability translates to lower maintenance costs over time, making steel treads a cost-effective solution for facilities that experience heavy foot traffic.

Moreover, steel stair treads are often treated or coated with materials that enhance their resistance to corrosion and slipping. This additional layer of protection not only extends the lifespan of the treads but also contributes to safety in environments where slippery conditions may arise. The combination of strength and safety features makes steel stair treads a reliable option for industries like manufacturing, hospitality, and commercial buildings, where both durability and longevity are vital for ensuring smooth operations and safeguarding users. With proper installation and maintenance, steel stair treads can provide years of dependable service, proving to be a smart investment in any high-traffic setting.

Selecting the Right Type of Steel Stair Tread for Your Environment

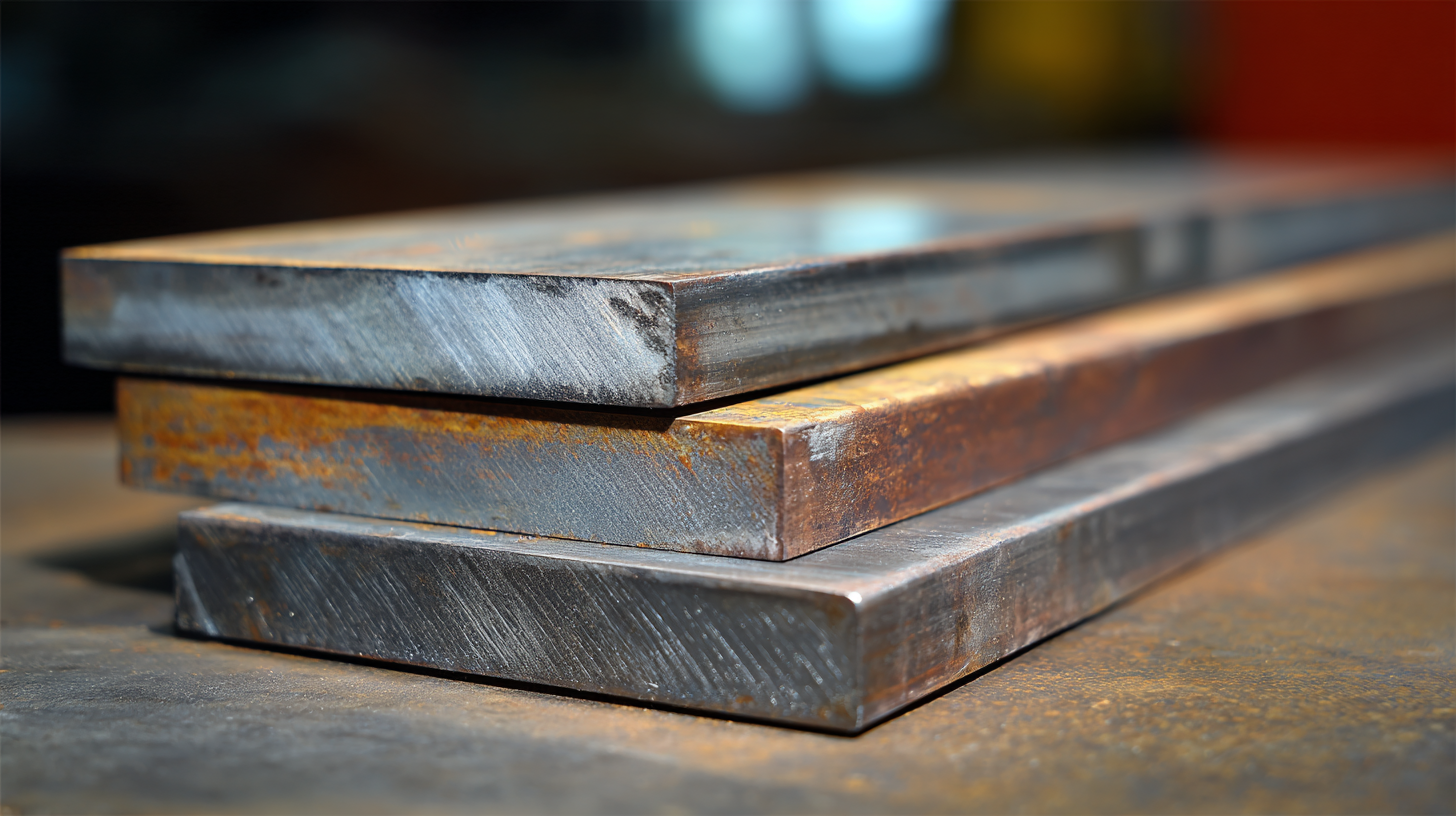

When selecting the right type of steel stair tread for high-traffic environments, it is crucial to consider both safety and durability. Steel stair treads come in various designs, including grooved, perforated, and slip-resistant options. Grooved treads, for instance, enhance traction, making them ideal for areas prone to wet or slippery conditions. This feature is especially important in commercial settings where the safety of employees and customers is a top priority.

Additionally, the choice of finish can significantly affect the performance of steel stair treads. A galvanized finish offers resistance to corrosion, while powder-coated treads can provide added aesthetic appeal and customization options. When evaluating the environment where the treads will be installed, factors such as exposure to chemicals, temperature fluctuations, and foot traffic patterns should be taken into account. By understanding these elements, one can select the most suitable steel stair tread that not only meets safety standards but also complements the overall functionality and design of the space.

Understanding the Benefits of Using Steel Stair Treads in High Traffic Areas - Selecting the Right Type of Steel Stair Tread for Your Environment

| Type of Steel Stair Tread | Material | Grip Type | Best for | Durability Rating | Cost per Unit ($) |

|---|---|---|---|---|---|

| Flat Steel Tread | Carbon Steel | Smooth | Indoor Low Traffic | Moderate | 15 |

| Diamond Plate Tread | Aluminum | Textured | Outdoor Medium Traffic | High | 25 |

| Non-Slip Tread | Stainless Steel | Aggressive | High Traffic Areas | Very High | 35 |

| Solid Ribbed Tread | Mild Steel | Ribbed | Heavy Duty Indoors | High | 20 |

Installing Steel Stair Treads: A Step-by-Step Guide

When considering the installation of steel stair treads in high traffic areas, it’s essential to understand the step-by-step process for optimal results. First, ensure you have the necessary tools and materials, including steel treads, screws, a drill, and safety gear. According to a report by the Occupational Safety and Health Administration (OSHA), slip and fall accidents account for over 20% of workplace injuries, highlighting the importance of installing durable materials that provide traction.

Begin by measuring the stair dimensions accurately to ensure a perfect fit for the treads. Next, prepare the surface by cleaning it thoroughly to remove any debris that could affect adhesion. Position the steel treads and mark where to drill holes for screws, typically at intervals of 12 to 16 inches, as suggested by industry guidelines for optimal stability. According to the American Institute of Steel Construction, properly installed steel treads can enhance the safety of stairways by up to 30%, making them a crucial choice for areas with heavy foot traffic.

Once the drilling is complete, place the treads, securing them tightly with screws. It’s advisable to finish with a non-slip coating to further enhance safety. Regular inspections and maintenance will ensure the longevity of the treads, elevating not just safety but also the structural integrity of the high traffic areas where they are installed.

Maintaining Steel Stair Treads for Optimal Safety and Performance

Maintaining steel stair treads is crucial for ensuring optimal safety and performance in high traffic areas. Regular inspection for signs of wear, corrosion, or damage can help identify potential hazards before they become serious issues. This proactive approach not only prolongs the lifespan of the treads but also protects users from slips, trips, and falls. Cleaning the treads regularly is equally important; a buildup of dirt or debris can create unsafe conditions, diminishing the effectiveness of the tread's anti-slip features.

Additionally, applying protective coatings can enhance the durability of steel stair treads. These coatings shield against environmental factors such as moisture and chemicals that can lead to corrosion over time. Periodically reapplying these coatings as directed can restore the tread’s grip and aesthetic appeal, ensuring that safety remains the top priority. Furthermore, ensuring proper installation and alignment of the treads can significantly reduce wear and enhance user experience. A sound maintenance routine is essential for maximizing the benefits of steel stair treads in busy settings, allowing facilities to uphold safety standards and improve overall performance.

Related Posts

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics

-

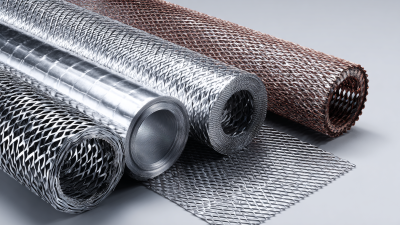

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights

-

Understanding the Benefits of Steel Grating in Industrial Applications

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Understanding the Importance of Stair Nosings for Safety and Aesthetics in Your Home