Understanding the Benefits of Steel Grating in Industrial Applications

In the industrial sector, the importance of selecting the right flooring solutions cannot be overstated, and steel grating emerges as a crucial player in this domain. According to a report by MarketsandMarkets, the global steel grating market is expected to reach $1.04 billion by 2025, demonstrating a strong CAGR of 5.8% from 2020. This robust growth can be attributed to the myriad benefits that steel grating provides, such as enhanced safety, durability, and cost-effectiveness in various applications including walkways, platforms, and drainage systems. Notably, the load-bearing capacity of steel grating surpasses that of traditional materials, making it ideal for heavy machinery environments. Furthermore, its maintenance-free nature and ability to withstand harsh conditions contribute to lower lifetime costs. As industries strive for efficiency and reliability, understanding the advantages of steel grating becomes imperative for optimally designed workspaces and operational safety.

Advantages of Steel Grating for Load-Bearing Applications

Steel grating has become an essential component in various industrial applications, particularly in load-bearing scenarios.

One of the primary advantages of steel grating is its exceptional strength-to-weight ratio, allowing it to support heavy loads while remaining lightweight.

This makes it a preferred choice for flooring, walkways, and platforms in manufacturing and construction environments, where safety and durability are critical.

Steel grating has become an essential component in various industrial applications, particularly in load-bearing scenarios.

One of the primary advantages of steel grating is its exceptional strength-to-weight ratio, allowing it to support heavy loads while remaining lightweight.

This makes it a preferred choice for flooring, walkways, and platforms in manufacturing and construction environments, where safety and durability are critical.

Moreover, steel grating is designed to provide excellent drainage and ventilation, which can help prevent the accumulation of water and debris on surfaces. This feature enhances safety by reducing slip hazards, making it ideal for environments where spills are common. Additionally, the open design of steel grating allows for optimal illumination and airflow, further promoting a safe and efficient working environment. Its resistance to corrosion and impact, when treated or galvanized, extends its lifespan, making it a cost-effective solution for long-term industrial use.

Enhancing Safety: Slip Resistance and Structural Integrity of Steel Grating

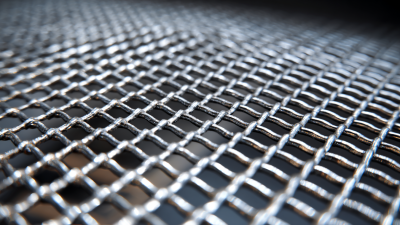

Steel grating is a vital component in various industrial applications, significantly enhancing safety through its inherent slip resistance and structural integrity. The surface of steel grating offers a secure footing, which is especially essential in environments where conditions can be wet or greasy. By preventing slips and falls, steel grating not only protects workers but also minimizes workplace accidents, fostering a safer operational environment.

When selecting steel grating for your facility, consider these tips: ensure the grate's surface has a suitable mesh pattern to maximize traction; install it at an appropriate angle to promote drainage; and regularly inspect the grating for wear and tear. Proper maintenance of steel grating can extend its lifespan and maintain its slip-resistance properties over time, ensuring continued safety for employees.

Moreover, the structural integrity of steel grating contributes to overall facility safety. Its robust construction can support substantial weights and withstand harsh conditions, making it a reliable choice for walkways, platforms, and machinery enclosures. Using high-quality materials and adhering to safety standards when installing steel grating will enhance both its resilience and effectiveness in creating a secure working environment.

Understanding the Benefits of Steel Grating in Industrial Applications

This chart illustrates the slip resistance and structural integrity ratings of various types of steel grating used in industrial settings. Higher ratings indicate better performance in enhancing safety. The data reflects common types of steel gratings and their respective ratings based on testing.

Cost-Effectiveness: Long-Term Savings with Durable Steel Grating Solutions

Steel grating has emerged as a cost-effective solution in industrial applications, providing long-term savings through its durability and low maintenance requirements. Unlike traditional flooring options, steel grating is designed to withstand extreme conditions and heavy loads, minimizing the likelihood of costly repairs or replacements. Its robust nature makes it ideal for factories, warehouses, and various industrial environments where safety and structural integrity are paramount.

The increasing market demand reflects the broader trend in the construction and industrial sectors, with a projected growth rate of 6.3% in the light gauge steel framing market. By reaching $66.89 billion by 2032, this growth signifies a shift towards materials that offer both strength and economic efficiency. Investing in durable steel grating solutions not only contributes to immediate safety and functionality but also ensures significant cost savings over time, reinforcing the trend towards sustainable industrial practices.

Versatility in Design: Customization Options for Industrial Projects

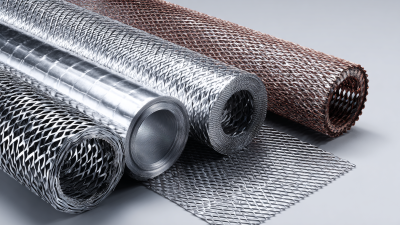

Steel grating stands out in industrial applications due to its versatility in design, offering numerous customization options to meet specific project needs. From varying mesh sizes to material choices, the adaptability of steel grating allows it to be tailored for diverse environments, such as walkways, platforms, and drainage systems. This customization ensures that projects can optimize safety and functionality while adhering to regulatory standards and design preferences.

Moreover, the ability to modify these grates allows for innovative solutions that align with modern industrial demands. For instance, incorporating anti-slip surfaces or specific load-bearing configurations can enhance safety and performance under unique conditions. As industries increasingly aim for sustainability, the versatility of steel grating can also accommodate eco-friendly practices, including the use of recycled materials and designs that minimize waste. This adaptability not only contributes to operational efficiency but also supports the overall goal of sustainable development in construction and industrial projects.

Environmental Impact: Recyclability and Sustainable Benefits of Steel Grating

Steel grating is a versatile material that offers considerable advantages in various industrial applications, particularly in terms of environmental sustainability. One of the most compelling features of steel grating is its recyclability. Made predominantly from steel, which is one of the most recycled materials globally, steel grating can be repurposed and reformed after its life cycle ends. This capability significantly reduces waste in landfills and promotes a circular economy, allowing manufacturers to adopt more sustainable practices.

Tips: When selecting steel grating for your projects, consider checking for certifications or claims about the material’s recycled content. Opting for products made from post-consumer or post-industrial recycled steel can further enhance the sustainability of your applications.

Moreover, the durable nature of steel ensures a long lifespan, which decreases the frequency of replacements and associated environmental footprints. By using steel grating, industries can also minimize the energy used for production compared to less durable materials. This efficiency contributes not only to cost savings but also to lower greenhouse gas emissions, making steel grating an environmentally responsible choice for organizations committed to sustainable practices.

Tips: Regular maintenance of steel grating can extend its lifespan even further. Simple approaches such as periodic inspections and cleaning can prevent rust and degradation, maximizing both performance and sustainability.

Related Posts

-

The Versatility and Benefits of Using Stainless Steel Mesh Screens in Everyday Applications

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

Exploring Metal Mesh Screen Innovations at the 138th Canton Fair 2025 with Industry Growth Insights

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Exploring the Growth of Steel Stair Treads at the 138th Canton Fair 2025 Industry Insights and Statistics