Top 2025 Stainless Steel Mesh Screen Uses and Benefits You Need to Know

In today's industrial and commercial landscapes, the significance of a stainless steel mesh screen is undeniable. These versatile and durable screens are designed to meet a variety of needs across multiple sectors, offering practical solutions for filtration, separation, and security. As we move toward 2025, the applications of stainless steel mesh screens are projected to expand, showcasing their role in enhancing efficiency and safety in various processes.

The benefits of using a stainless steel mesh screen are manifold. Known for their strength and resistance to corrosion, these screens provide an ideal choice for environments that demand durability and reliability. From construction to food processing and even in residential applications, stainless steel mesh screens offer unparalleled functionality. This comprehensive overview will explore the top uses of stainless steel mesh screens, emphasizing their advantages and the innovative ways they can be implemented in different fields. As industries evolve, understanding the critical roles these screens play will be essential for maximizing performance and ensuring safety in everyday operations.

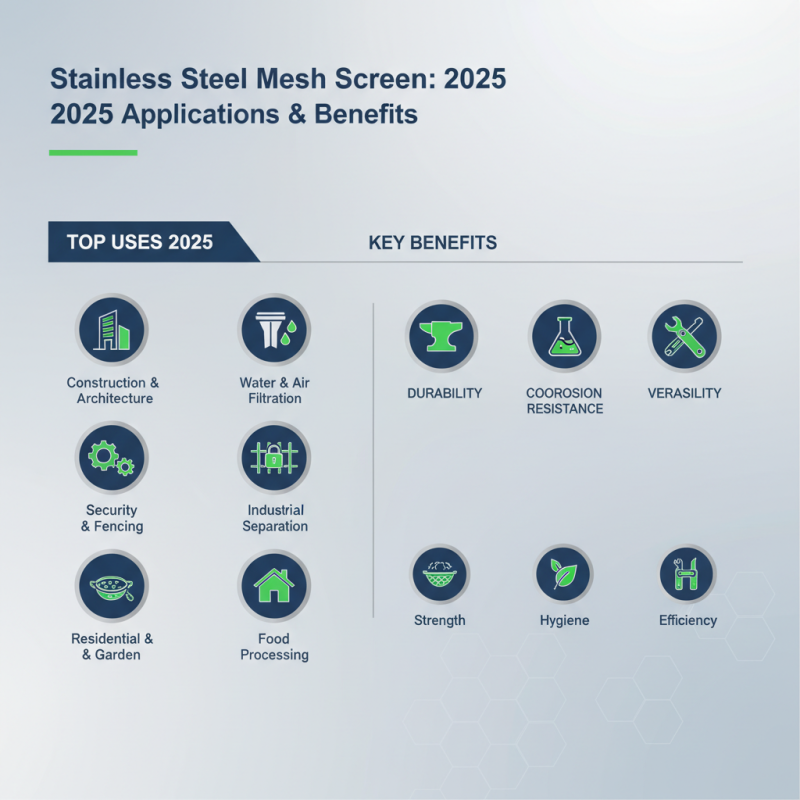

Applications of Stainless Steel Mesh Screens in Various Industries

Stainless steel mesh screens are widely acknowledged for their versatility and strength, making them essential in a variety of industries. One prominent application is in the food and beverage sector, where these screens are used in filtration processes to ensure the purity of products. The fine mesh prevents contaminants while allowing liquids to pass through, enhancing quality control and compliance with health regulations. Additionally, their corrosion resistance makes them ideal for environments exposed to moisture, ensuring longevity and reliability in production.

Another significant area of application is in the construction and architectural industries. Stainless steel mesh screens are used for safety barriers, facades, and ventilation systems, combining aesthetic appeal with practicality. Their robust nature allows them to withstand harsh weather, making them suitable for both indoor and outdoor structures. Moreover, in agriculture, these screens serve as protective barriers, preventing pests from damaging crops while allowing air and sunlight to reach the plants. This multi-faceted utility showcases how stainless steel mesh screens meet the diverse needs of various sectors, contributing to efficiency and safety in operations.

Key Benefits of Using Stainless Steel Mesh Screens

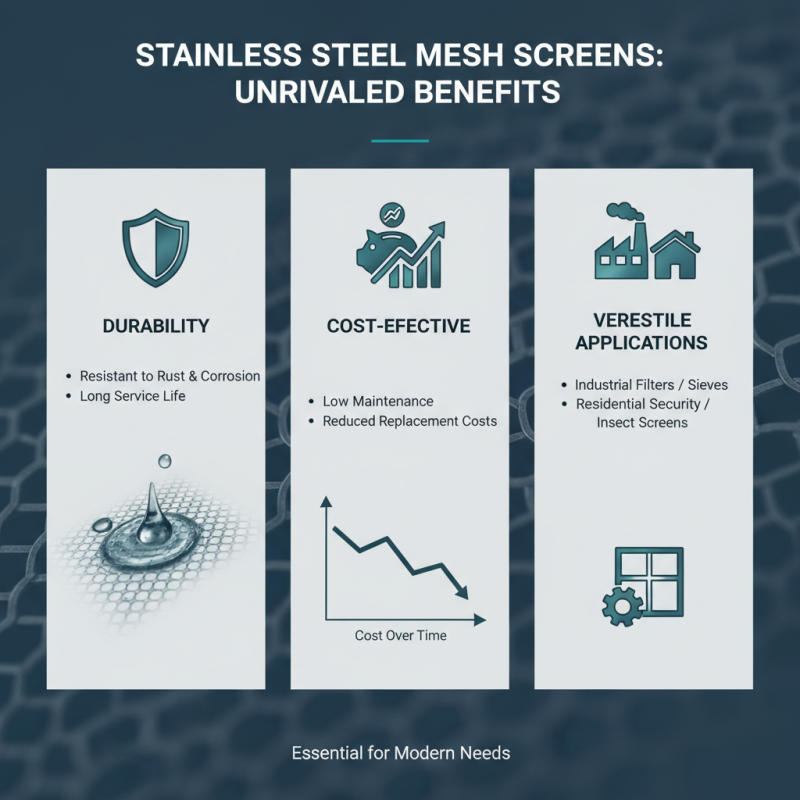

Stainless steel mesh screens provide a host of benefits that make them indispensable in various applications. One of the primary advantages is their durability. Stainless steel is inherently resistant to rust and corrosion, which ensures that the mesh screens maintain integrity and functionality over time, even in harsh environments. This longevity translates to lower maintenance costs and extended service life, making stainless steel an economical choice for industrial and residential uses alike.

Another significant benefit of stainless steel mesh screens is their versatility. These screens can be manufactured in various mesh sizes and configurations, allowing for tailored solutions based on specific filtration or airflow requirements. This adaptability makes them ideal for a range of applications, from agricultural sieves and architectural designs to food processing and automotive uses. Moreover, the strength of stainless steel allows it to withstand considerable stress and strain, making it suitable for high-pressure environments where other materials might fail. This combination of durability, adaptability, and strength positions stainless steel mesh screens as a reliable choice in a multitude of sectors.

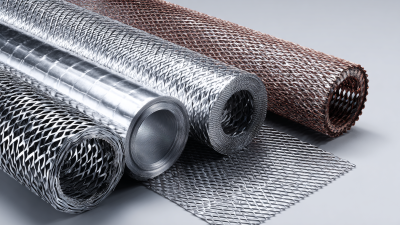

Different Types of Stainless Steel Mesh Screens and Their Specifications

Stainless steel mesh screens are versatile tools employed across various industries due to their strength, durability, and resistance to corrosion. There are several types of stainless steel mesh screens, each with distinct specifications tailored to specific applications. For instance, welded wire mesh typically features a uniform opening size and can be utilized for filtration, while woven wire mesh offers greater flexibility in terms of opening patterns, making it suitable for architectural applications.

The specifications of stainless steel mesh screens can vary significantly. The wire diameter can range from 0.016 inches to 0.25 inches, with opening sizes spanning from 20 microns to several inches. According to a report by MarketsandMarkets, the global market for stainless steel mesh is projected to grow at a CAGR of 5.6% from 2021 to 2026, reflecting the increasing demand for these materials in construction, automotive, and food processing industries. Additionally, different grades of stainless steel, such as 304 and 316, exhibit distinct levels of corrosion resistance, with grade 316 demonstrating superior performance in marine applications due to its higher nickel and molybdenum content.

Maintenance Tips for Prolonging the Life of Stainless Steel Mesh Screens

Maintaining stainless steel mesh screens is essential to ensure their longevity and optimal performance. Regular cleaning is one of the most beneficial practices for prolonging the life of these screens. Depending on the environment and the type of debris they encounter, screens should be inspected and cleaned regularly. A thorough wash with warm, soapy water can effectively remove dust, dirt, and residues, preventing blockage and potential wear. For tougher stains or buildup, a gentle scrub with a non-abrasive brush and a diluted vinegar solution can help restore the screen's integrity without causing damage.

Another crucial aspect of maintenance is proper handling during installation and removal. Stainless steel mesh screens can be susceptible to dents and deformation if mishandled, so using protective gloves and tools can minimize the risk of introducing imperfections. Additionally, storing the screens in a dry, cool place when not in use can prevent exposure to corrosive elements and environmental factors that could lead to deterioration. Regularly checking the frame for signs of rust or wear will also help identify potential issues before they necessitate costly repairs or replacements. By implementing these maintenance tips, users can enjoy the benefits of durable, reliable stainless steel mesh screens for years to come.

Top 2025 Stainless Steel Mesh Screen Uses and Benefits

Comparative Analysis: Stainless Steel vs. Other Mesh Materials

When comparing stainless steel mesh screens with other mesh materials, several key factors come into play, including durability, corrosion resistance, and versatility. Stainless steel offers superior strength and longevity, making it an ideal choice for high-stress applications. According to a report from the Global Market Insights (2023), the demand for stainless steel mesh is projected to grow due to its extensive use across industries such as construction, automotive, and food processing. Stainless steel mesh not only withstands extreme temperatures but also resists rust and chemical degradation, outperforming alternatives like plastic or nylon under similar conditions.

Conversely, while materials like aluminum and copper mesh may be lightweight and cost-effective, they lack the same level of durability, particularly in harsh environments. For example, aluminum tends to corrode faster than stainless steel when exposed to moisture or chemicals, leading to increased maintenance costs. This comparative analysis underscores the importance of selecting the right mesh material based on the specific application requirements.

Tip 1: When choosing a mesh material, consider the environmental factors it will face, such as humidity, temperature, and exposure to chemicals. This can greatly influence the longevity and performance of the mesh.

Tip 2: For applications requiring high strength and resistance to corrosive environments, stainless steel should be your go-to choice, especially if the budget allows for it. Investing in quality material will pay off in the long run through reduced maintenance and replacement costs.

Related Posts

-

What is Stainless Steel Mesh Screen? Exploring Benefits, Applications, and Market Trends in 2023

-

2025 Top Uses and Benefits of Expanded Metal Sheet in Construction and Design

-

What is Welded Wire and How to Choose the Right Type for Your Projects

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Mesh

-

2025 How to Choose the Right Drain Grate for Your Landscape Design