2025 Top Fiberglass Grating Trends: Maximize Strength and Safety in Industrial Applications

As industries continue to evolve, the need for durable and reliable materials has never been more critical. One such material that has gained considerable attention is fiberglass grating. In 2025, the latest trends reveal that fiberglass grating not only maximizes strength but also enhances safety across various industrial applications. This article explores the transformative developments in fiberglass grating, shedding light on innovative designs and materials that are set to redefine industry standards.

Utilizing advanced manufacturing techniques and cutting-edge technology, the fiberglass grating of the future promises increased load-bearing capacity and longevity while minimizing the risk of accidents. With a growing emphasis on workplace safety and efficiency, companies are leaning towards fiberglass grating as a preferred solution for flooring, walkways, and support structures. This shift not only addresses the demands for higher performance but also aligns with eco-friendly initiatives, making fiberglass grating a sustainable choice for modern industries.

In concluding this exploration of 2025's top fiberglass grating trends, we will delve into practical insights that can assist businesses in making informed decisions regarding their material choices. By understanding the latest advancements and how they can be implemented effectively, organizations will be better equipped to enhance their operations while ensuring the safety and well-being of their workforce.

Innovative Fiberglass Grating Designs for Enhanced Load-Bearing Capacity

The industrial landscape is continuously evolving, and fiberglass grating designs are at the forefront of this transformation, particularly in 2025. With a strong emphasis on maximizing load-bearing capacity, innovative designs are being developed to meet the rigorous demands of various industrial applications. These advancements not only enhance the structural integrity of flooring and walkways but also address safety concerns that are paramount in workplaces where heavy machinery and foot traffic intersect.

One notable trend is the integration of advanced composite materials that provide superior strength-to-weight ratios. These materials allow manufacturers to create grating systems that are significantly lighter yet capable of supporting increased loads. Additionally, the introduction of modular grating systems facilitates easier installation and maintenance, reducing downtime and labor costs. Coupled with slip-resistant surfaces and corrosion-resistant properties, the new designs promise to deliver an unprecedented level of safety and durability, ensuring that industrial environments are both efficient and secure for workers.

Advancements in Anti-Slip Coatings for Improved Safety Standards

In 2025, the focus on antif-slip coatings for fiberglass grating is set to revolutionize safety standards in industrial applications. With slipping accidents accounting for 30% of workplace injuries, the need for reliable anti-slip solutions has never been more pressing. According to a recent report from the National Safety Council, workplaces that adopted advanced anti-slip coatings saw a 40% reduction in slip-related incidents. This significant decrease not only enhances worker safety but also minimizes potential liability costs for employers.

Advancements in technology have led to the development of new anti-slip coating materials that offer superior durability and performance. For instance, the use of polyurethane-based coatings has shown a marked improvement in resistance against wear and chemical degradation, extending the lifespan of fiberglass grating installations. Furthermore, industry analyses indicate that the market for anti-slip coatings is expected to grow by 15% annually, reflecting an increasing demand for safety in industrial settings. As businesses invest in these innovative solutions, the synergy between increased safety and operational efficiency will become a key driver for growth in this sector.

The Integration of Smart Technology in Fiberglass Grating Solutions

As we look ahead to 2025, the integration of smart technology into fiberglass grating solutions is poised to revolutionize industrial applications. This transformation is driven by increasing demands for safety, efficiency, and durability in hazardous environments. According to a report by Research and Markets, the global market for smart industrial materials is expected to grow at a CAGR of over 15% between 2023 and 2028, highlighting a significant shift toward advanced material solutions. Fiberglass grating, enhanced with smart sensors, can monitor stress levels, detect impacts, and provide real-time feedback to maintenance teams, thereby minimizing downtime and enhancing operational safety.

Moreover, the incorporation of IoT technology in fiberglass grating design allows for the seamless integration of data analytics into industrial operations. A recent study by Grand View Research indicates that the smart manufacturing sector is estimated to reach USD 420 billion by 2026, underscoring the importance of adopting innovative materials like smart fiberglass grating. These advancements not only contribute to structural integrity but also significantly enhance worker safety by alerting personnel to potential hazards, thereby fostering a safer workplace environment.

As industries continue to prioritize sustainability and safety, the role of smart fiberglass grating solutions will undeniably expand, shaping the future of industrial infrastructures.

Sustainable Materials: The Future of Fiberglass Grating Production

The future of fiberglass grating production is increasingly leaning towards

sustainable materials, reflecting a broader trend in industrial applications

aimed at reducing environmental impact. Traditional fiberglass manufacturing processes often involve harmful chemicals and non-renewable resources.

However, advancements in material science have led to the development of eco-friendly alternatives that utilize recycled materials and bio-based resins.

These innovations not only lower the carbon footprint associated with production but also enhance the properties of the grating, resulting in products that are both

strong and durable.

Moreover, sustainable fiberglass grating options provide facilities with the ability to comply with stricter

environmental regulations while also meeting their operational needs. By integrating renewable and recyclable materials, manufacturers can produce grating

solutions that maintain high performance without compromising safety and structural integrity. This shift not only speaks to the growing demand for sustainability

in industrial practices but also reflects a commitment to responsible production methods that can benefit both businesses and the planet.

As industries continue to prioritize sustainability, the adoption of eco-friendly fiberglass grating will likely play a pivotal role in shaping the future of

industrial applications.

Regulatory Changes Impacting Fiberglass Grating Use in Industrial Settings

In recent years, stringent regulatory changes have reshaped the landscape for fiberglass grating in industrial applications. The growing emphasis on safety and environmental stewardship has prompted many industries to reassess their materials and practices. According to a recent report by the American Composites Manufacturers Association (ACMA), the demand for fiberglass reinforced plastics is expected to grow by 6% annually through 2025, driven largely by these regulatory pressures. Industries such as chemical processing, oil and gas, and wastewater treatment are particularly impacted, as they must comply with new standards that mandate the use of materials improving both worker safety and operational reliability.

In response to these regulations, manufacturers are innovating to enhance the performance of fiberglass grating products. Data from a 2022 market analysis by Technavio indicates that advancements in resin technology and reinforcement techniques are enabling fiberglass grating to achieve superior strength-to-weight ratios, essential for applications requiring outstanding durability under harsh conditions. Furthermore, compliance with regulations posits a significant opportunity for growth; companies deploying certified materials not only ensure safety but also stand to benefit from reduced liability risks and potentially lower insurance premiums. Enhanced product offerings in terms of design flexibility and anti-slip properties further bolster the appeal of fiberglass grating in an increasingly safety-conscious industry landscape.

2025 Top Fiberglass Grating Trends

This bar chart illustrates key trends in fiberglass grating for 2025, focusing on various factors such as safety standards, load capacity, and environmental considerations, each rated on an importance scale from 1 to 10. These insights reflect the evolving demands and regulatory landscape impacting the use of fiberglass grating in industrial applications.

Related Posts

-

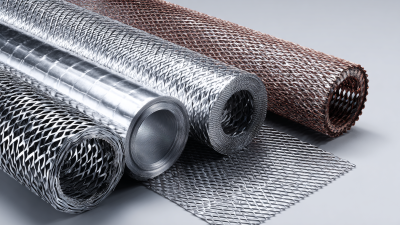

Exploring the Versatility of Metal Mesh Screens in Modern Design and Engineering

-

Why Metal Mesh Screens Are Essential for Your Home and Business Needs

-

The Ultimate Guide to Choosing the Right Stainless Steel Mesh Screen for Your Home Projects

-

What is a Perforated Metal Sheet? A Comprehensive Guide to Its Uses and Benefits

-

5 Best Wire Mesh Panels: Enhancing Security with 75% Increased Durability Over Traditional Fencing

-

Expanded Metal Innovations at the 138th Canton Fair 2025 Shaping the Future of Manufacturing in China